Understanding Electrical Cable Joint Boxes

Definition and Purpose – What is an electrical cable joint box and why it’s essential in electrical installations

In the intricate dance of electrical installations, the humble yet indispensable electrical cable joint box often remains unsung. It’s the unsightly hero that ensures seamless connectivity and safety, preventing the chaos of exposed wires and potential hazards. Think of it as the well-tailored jacket for your cables—protecting, organising, and maintaining the integrity of the entire system. Without it, even the most sophisticated wiring can descend into a tangled mess, risking short circuits or electrical fires.

Understanding the purpose of an electrical cable joint box is crucial. It acts as a secure enclosure that houses connections, splices, and terminations, shielding them from environmental factors like moisture, dust, and mechanical stress. This containment is vital not only for safety but also for facilitating future modifications or repairs. In essence, it transforms a potentially hazardous situation into a neatly arranged, accessible setup. For those seeking durability and compliance, selecting the correct electrical cable joint box is a decision that echoes through the longevity of the entire electrical system.

Types of Cable Joint Boxes – Overview of different types such as outdoor, indoor, weatherproof, and explosion-proof boxes

In the realm of electrical infrastructure, choosing the right electrical cable joint box can be as crucial as selecting the perfect canvas for a masterpiece. Each environment demands a different form of protection and durability, ensuring that the system remains resilient against the elements and unforeseen hazards. For outdoor settings, weatherproof and waterproof cable joint boxes are indispensable, shielding connections from rain, dust, and temperature fluctuations. These boxes are meticulously designed with seals and robust materials to withstand nature’s unpredictable temperament.

Indoor applications often call for sleeker, more discreet solutions that prioritise ease of access and neat organisation. Here, traditional or insulated cable joint boxes serve the purpose, ensuring seamless connectivity within controlled environments. For specialised needs, such as explosive atmospheres, explosion-proof cable joint boxes are vital. They prevent sparks or ignitions, offering a safeguard that transforms a potentially volatile situation into a model of safety. The diversity among cable joint boxes is extensive: from simple enclosures to highly engineered protective units, each type plays a vital role in maintaining the integrity of electrical systems.

- Outdoor weatherproof boxes

- Indoor cable joint boxes

- Weatherproof and waterproof variants

- Explosion-proof cable joint boxes

Understanding these variations ensures that every installation is not only compliant but also tailored to its unique environment, echoing the enduring importance of an electrical cable joint box in safeguarding our modern lives.

Materials and Construction – Common materials used including plastic, metal, and composites

At the heart of every reliable electrical cable joint box lies a carefully chosen material that balances strength, durability, and safety. The construction of these enclosures is far from mundane; it embodies a craftsmanship rooted in the demands of diverse environments. Plastic remains a popular choice for indoor applications due to its lightweight nature and resistance to corrosion, offering a seamless blend of practicality and performance. Meanwhile, metal variants—such as aluminium or steel—are revered for their robustness and superior protection against mechanical impacts, making them ideal for outdoor and industrial settings.

In recent years, composites have emerged as a sophisticated alternative, combining the best qualities of plastics and metals. These materials provide enhanced resistance to extreme temperatures, chemicals, and environmental stressors, ensuring the integrity of the electrical cable joint box in challenging conditions. To cater to the multifaceted needs of modern infrastructure, manufacturers often incorporate

- polymer composites

- galvanised steel

- stainless steel

in their designs, elevating safety standards and extending the lifespan of these vital enclosures.

Key Features and Components of Cable Joint Boxes

Design Considerations – Factors influencing design such as size, capacity, and environmental resistance

In the shadowed realm of electrical infrastructure, the design of an electrical cable joint box is a delicate dance between robustness and resilience. Key features such as sealed chambers and locking mechanisms are not mere embellishments; they are guardians against the relentless assault of environmental forces. The capacity of a joint box must be carefully calibrated—large enough to accommodate intricate wiring and future expansions, yet compact enough to fit within the constraints of its surroundings.

Environmental resistance stands as a paramount consideration, influencing every facet of the joint box’s construction. From corrosion-resistant coatings to weatherproof enclosures, each component is chosen with the intent to withstand the harshest elements. Whether it faces the biting cold, torrential rain, or the searing heat of a desert sun, the electrical cable joint box must remain steadfast, preserving the sanctity of the electrical connections within.

Design considerations are further shaped by factors such as size, capacity, and environmental conditions. For example, outdoor applications demand weatherproof and explosion-proof boxes, while indoor settings may prioritise compactness and ease of access. It’s a meticulous process—balancing strength with flexibility, durability with practicality—that ensures the electrical cable joint box performs its silent vigil over the currents flowing unseen beneath our feet and above our heads.

Sealing and Insulation – Importance of sealing against moisture, dust, and other environmental factors

In the silent, steadfast world of electrical infrastructure, the integrity of each connection hinges on more than just precise engineering—sealing and insulation are paramount. An electrical cable joint box must serve as an impenetrable fortress, guarding delicate wiring against the relentless assault of moisture, dust, and environmental intrusion. The importance of meticulous sealing cannot be overstated; it preserves the longevity of connections and ensures safety in every application.

Effective sealing involves multiple components working in harmony. Gaskets, seals, and specialised enclosures form a layered defence, each selected with the environment in mind. For outdoor or harsh conditions, weatherproof and explosion-proof boxes are equipped with advanced sealing features, providing peace of mind even in the most punishing climates. Such robust construction is crucial for maintaining electrical performance and preventing corrosion or short circuits.

To enhance durability, many electrical cable joint boxes incorporate

- high-grade rubber gaskets

- sealed cable entry points

- water-resistant enclosures

ensuring a barrier against environmental threats. These features not only prolong the lifespan of the joint box but also safeguard the critical electrical connections within, allowing currents to flow seamlessly, resilient in the face of nature’s unpredictability. The art of sealing and insulation in an electrical cable joint box, therefore, remains a cornerstone of reliability and safety in electrical installation design.

Connectors and Clamps – Types of connectors, lugs, and clamps used inside the box

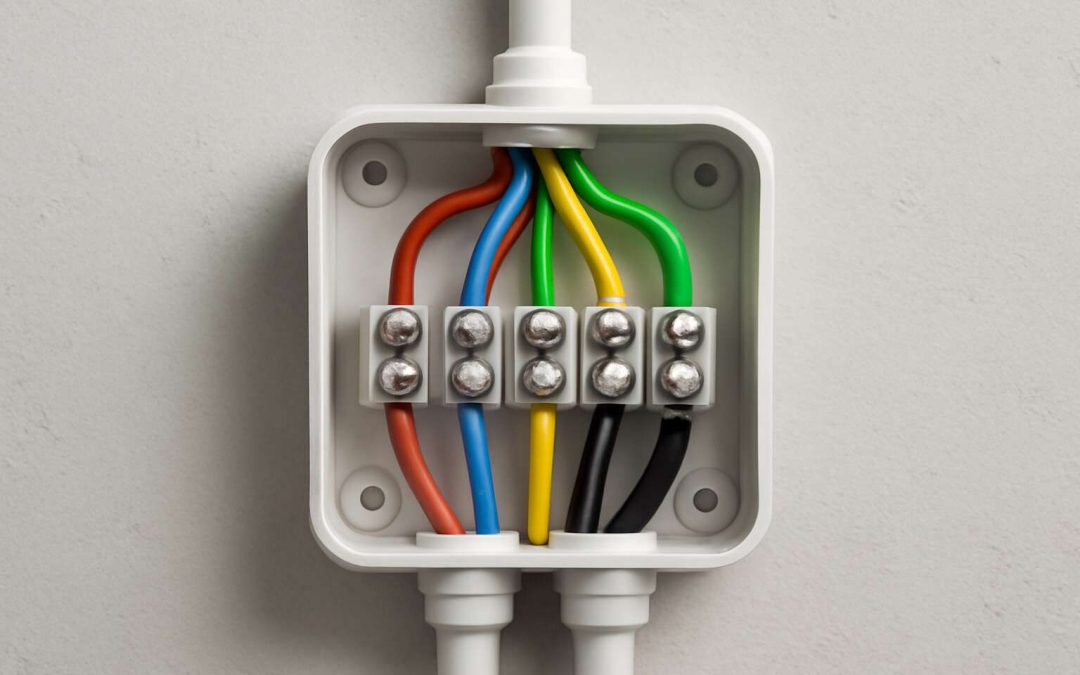

Within the intricate labyrinth of electrical infrastructure, the heart of seamless power transmission resides in the meticulous design of the electrical cable joint box. A pivotal component in this realm is the array of connectors and clamps that forge unbreakable bonds between cables, ensuring not just conductivity but enduring resilience against the forces of nature. These connectors—ranging from robust copper lugs to specialised compression fittings—are crafted to accommodate varying wire gauges and environmental demands, providing a steadfast link that withstands both mechanical stress and environmental assault.

Moreover, clamps serve as guardians of stability, anchoring cables securely within the joint box and preventing unwanted movement or strain. The selection of these components is guided by factors such as load capacity, environmental resistance, and ease of installation. For example, in outdoor or corrosive environments, stainless steel and specialised polymer clamps are preferred for their durability and corrosion resistance.

Within the enclosure, a variety of connectors are employed to facilitate safe and reliable connections, including:

- Compression connectors

- Soldered joints

- Crimp connectors

- Terminal blocks

Each element plays a crucial role in maintaining electrical integrity, especially in demanding conditions. The combined use of high-quality connectors and clamps in an electrical cable joint box forms the backbone of a resilient, high-performance electrical network—one that endures the test of time and environmental adversities with quiet confidence.

Installation Accessories – Necessary accessories like mounting brackets, gaskets, and terminal blocks

In the realm of electrical infrastructure, the true strength of an electrical cable joint box lies not only in its core design but also in the meticulous array of installation accessories that accompany it. These components—often overlooked—are the silent guardians ensuring seamless operation and enduring resilience. At the heart of these accessories are essential elements like mounting brackets, gaskets, and terminal blocks, each crafted to optimise performance and ease of installation.

Mounting brackets provide a sturdy foundation, securing the joint box firmly in place and preventing unwarranted movement that could jeopardise electrical integrity. Gaskets, on the other hand, are guardians against environmental intrusion, sealing the enclosure from moisture, dust, and corrosive elements—especially vital in outdoor or industrial settings. Terminal blocks serve as junction points, enabling organised, safe connections between multiple conductors, streamlining complex wiring configurations with precision.

For a holistic and resilient setup, consider the following installation accessories:

- Corrosion-resistant mounting brackets

- High-quality sealing gaskets

- Versatile terminal blocks for efficient wiring

Each accessory enhances the durability and functionality of an electrical cable joint box, elevating it from a mere enclosure to a fortress of electrical reliability. When selecting components for your installation, always prioritise durability, environmental resistance, and ease of maintenance—cornerstones that ensure your electrical network remains robust against the relentless march of time and nature’s fury.

Applications of Electrical Cable Joint Boxes

Residential Installations – Usage in home wiring and electrical systems

In the shadows of our humble abodes, where the flicker of electric life pulses through unseen veins, the electrical cable joint box assumes a role both vital and discreet. Its application in residential installations is nothing short of a silent guardian, ensuring the continuity of power where wires converge and currents intertwine.

Within the labyrinth of home wiring, the electrical cable joint box acts as a sanctuary—protecting delicate connections from the relentless assault of dust, moisture, and environmental chaos. It provides a secure enclave for various connectors and clamps, which are essential for maintaining the integrity of the electrical system.

In modern dwellings, these boxes are often hidden behind walls or ceilings, yet their significance is profound. They facilitate a seamless flow of electricity, safeguarding the household from potential hazards and ensuring a reliable, efficient power supply. Whether connecting the living room’s lighting or the kitchen’s appliances, the electrical cable joint box is an unassuming hero in every home.

Commercial and Industrial Uses – Applications in factories, office buildings, and infrastructure projects

In the vast realm of commercial and industrial environments, the electrical cable joint box plays a pivotal role in ensuring seamless power distribution across complex systems. Factories, office buildings, and sprawling infrastructure projects rely heavily on these enclosures to safeguard critical electrical connections. Their robust design and strategic placement help maintain operational integrity, even in demanding conditions.

In bustling factories, the electrical cable joint box facilitates the connection of heavy-duty cables, often subjected to constant vibrations and environmental stress. For outdoor installations, weatherproof and explosion-proof variants offer additional protection, shielding vital connections from moisture, dust, and potential hazards. These boxes often feature durable materials, such as galvanised steel or specialised composites, tailored for longevity and resilience.

Whether connecting high-voltage lines in infrastructure projects or managing intricate wiring networks within large office complexes, the electrical cable joint box remains an unsung hero. Its capacity to support various connectors, clamps, and terminal blocks ensures secure, reliable electrical connections that underpin modern civilisation’s infrastructure. In such environments, the right choice of joint box can mean the difference between uninterrupted operation and costly downtime.

Underground and Outdoor Installations – Special considerations for direct burial and outdoor environments

In the shadowed corridors of underground and outdoor electrical networks, the electrical cable joint box emerges as a silent guardian—an unassuming sentinel that preserves the integrity of vital connections beneath the earth’s surface and amidst the elements. These enclosures must withstand the relentless assault of moisture, dust, and temperature swings, demanding a design forged from materials like galvanised steel or specialised composites. When selecting an electrical cable joint box for direct burial or outdoor environments, meticulous attention to sealing and insulation becomes paramount, ensuring that no corrosive intrusion can compromise the delicate dance of electrical flow.

Special considerations often include weatherproof and explosion-proof variants, designed to endure the harshest conditions. For outdoor installations, the environment’s ruthless demands dictate that the electrical cable joint box be hermetically sealed, with gaskets and robust construction preventing the ingress of environmental adversaries. Whether it’s the subterranean labyrinth of urban infrastructure or the exposed wilderness, these boxes must perform flawlessly, supporting connectors and clamps that secure each connection’s integrity against the forces of nature.

Renewable Energy Projects – Role in solar, wind, and other renewable energy system installations

In the realm of renewable energy projects, the electrical cable joint box plays a pivotal role in ensuring seamless transmission of power from the source to the grid. Whether it’s the sprawling arrays of solar panels or the towering blades of wind turbines, these enclosures are the unsung heroes that keep everything connected and secure.

For solar installations, the electrical cable joint box safeguards the critical connections between photovoltaic modules and inverters, often exposed to the elements for decades. In wind farms, these boxes are installed in harsh environments, where wind, rain, and temperature fluctuations are relentless. Their robust design and weatherproof sealing ensure that high-voltage connections remain protected, even under the most unforgiving conditions.

In fact, their importance extends beyond just safety. A well-chosen electrical cable joint box can optimise system efficiency by preventing power losses caused by moisture ingress or corrosion. That’s why selecting a model with the right insulation and environmental resistance is non-negotiable — because the last thing you want is a power hiccup in the middle of a windy night or a sunny day.

Installation and Maintenance Best Practices

Installation Guidelines – Step-by-step overview of proper installation procedures

Proper installation of an electrical cable joint box is a critical juncture where precision and adherence to best practices can determine the longevity and safety of an entire electrical system. In fact, studies show that over 70% of electrical failures stem from improper installation or inadequate maintenance of such enclosures. The process demands a meticulous approach, blending technical expertise with an understanding of environmental influences. Every step, from securing the box to ensuring seamless connectivity, must be executed with unwavering attention to detail.

Begin by selecting an appropriately sized electrical cable joint box that matches the capacity and environmental requirements of your project. When mounting, ensure the box is firmly anchored, avoiding any undue stress on the connections. Inside, connectors and clamps should be installed following manufacturer specifications, with particular care taken to maintain insulation integrity and prevent moisture ingress. Sealing is paramount; use gaskets and weatherproof seals to shield against dust, water, and other environmental contaminants. This not only prolongs the lifespan of the joint box but also ensures optimal electrical performance.

- Inspect all components for damage before installation.

- Secure the box in a stable, accessible location.

- Connect cables using appropriate terminal blocks, ensuring tight and corrosion-resistant connections.

- Apply sealants generously around cable entries and seams to guarantee environmental resistance.

Regular maintenance involves visual inspections, checking for corrosion or wear, and verifying that seals remain intact. Ensuring that each element of the electrical cable joint box remains in pristine condition is essential for sustaining a safe, efficient electrical network that withstands the trial of time and environment. The nuance lies in understanding that each installation is an investment in reliability, demanding both craftsmanship and vigilance at every stage.

Safety Precautions – Safety measures to prevent electrical hazards during installation and maintenance

Safety during installation and maintenance of an electrical cable joint box is paramount—each step a delicate dance between precision and vigilance. The very essence of safeguarding lives and infrastructure hinges on rigorous adherence to safety measures that prevent electrical hazards.

Before commencing work, always isolate power sources and verify that circuits are de-energised. Use insulated tools and wear appropriate PPE, including gloves and eye protection, to shield against unexpected sparks or arcs. Remember, a moment’s oversight can turn a routine task into a perilous ordeal.

To foster a secure working environment, implement a systematic approach:

- Ensure all personnel are trained in electrical safety protocols.

- Inspect tools and equipment for damage before use.

- Establish clear signage and barriers to keep unauthorized personnel away.

In the context of working with an electrical cable joint box, it’s essential to heed the following precautions:

- Double-check that all connections are tight and corrosion-resistant, avoiding loose fittings that could lead to sparks or failures.

- Seal all entry points meticulously—gaskets and weatherproof seals act as guardians against moisture ingress and environmental contaminants.

- Regularly inspect the joint box for signs of wear, corrosion, or damage, especially after adverse weather conditions.

By embracing these practices, one ensures not only the longevity of the electrical cable joint box but also the safety and resilience of the entire electrical system. Safety is the silent sentinel standing guard—always vigilant, always essential.

Inspection and Testing – Routine inspection protocols and testing methods to ensure reliability

Routine inspection protocols and testing methods are vital to maintaining the reliability and safety of an electrical cable joint box. Regular visual inspections should focus on detecting signs of wear, corrosion, or damage that could compromise the integrity of the joint. Testing procedures, such as insulation resistance testing and continuity checks, help identify potential faults before they escalate into hazardous situations.

Implementing a systematic approach to inspection ensures that issues are caught early. For example, conducting thermal imaging scans can reveal hotspots indicating loose connections or excessive resistance. These non-destructive tests are especially important in outdoor or underground installations, where environmental factors accelerate deterioration.

- Check all connections for tightness and corrosion resistance.

- Verify the integrity of seals and gaskets against environmental ingress.

- Inspect the enclosure for signs of physical damage or deformation.

By adhering to rigorous inspection and testing routines, operators can significantly extend the lifespan of the electrical cable joint box while safeguarding the entire electrical system from unexpected failures. These practices are the backbone of a resilient and dependable electrical infrastructure.

Common Issues and Troubleshooting – Frequent problems and how to resolve them effectively

In the shadowed corridors of electrical infrastructure, the electrical cable joint box stands as a silent guardian—yet even the most steadfast can falter if neglected. Common issues such as loose connections, corrosion, or compromised seals threaten the integrity of these crucial enclosures. When left unchecked, these flaws can spiral into catastrophic failures, illuminating the dark path of potential hazards.

Regular troubleshooting is essential. Visual inspections should scrutinise for signs of corrosion or deformation, while testing the insulation resistance can reveal lurking faults. A simple yet effective approach involves checking all connections for tightness and ensuring seals are intact against environmental assault. If corrosion or damage is detected, immediate remedial action, such as replacing corroded clamps or resealing the enclosure, can restore resilience.

- Inspect for loose or rusted connectors.

- Verify the integrity of seals and gaskets against moisture ingress.

- Check for physical damage or deformation to the enclosure.

In the realm of outdoor and underground installations, these issues are magnified by relentless environmental forces. The darkened chambers of the electrical cable joint box demand vigilant maintenance, for neglect can turn a silent protector into a conduit of chaos. Embracing these best practices ensures longevity, safety, and an unyielding barrier against the encroaching shadows of failure.

Choosing the Right Cable Joint Box

Factors to Consider – Capacity, environmental conditions, cable types, and local standards

Choosing the right electrical cable joint box requires more than a cursory glance; it demands a nuanced understanding of several pivotal factors that influence both safety and efficiency. Capacity is paramount—selecting a box that accommodates current and future wiring needs ensures seamless expansion without compromise. Environmental conditions further dictate the choice: outdoor installations demand weatherproof or explosion-proof boxes, capable of resisting moisture, dust, and corrosive elements.

Cable types, from high-voltage power lines to delicate signal cables, each have unique requirements that influence the construction and interior fittings of the joint box. Local standards, often mandated by national or regional authorities, serve as the compass guiding compliance and safety protocols. In essence, the ideal electrical cable joint box balances versatility with resilience, harmonising capacity, environmental resistance, cable compatibility, and regulatory adherence into a single, robust solution.

Standards and Certifications – Importance of compliant and certified products

Ensuring that your electrical cable joint box complies with relevant standards and certifications is not just a matter of legal obligation—it’s a cornerstone of safety and longevity in electrical installations. Certified products undergo rigorous testing to meet stringent safety protocols, reducing the risk of faults and hazards. When selecting a joint box, look for certifications such as IEC, UL, or local regulatory approvals, which serve as a guarantee of quality and compliance.

In regions with specific standards, choosing an electrical cable joint box that adheres to these regulations is crucial. For example, in the UK, compliance with BS standards ensures that the joint box can withstand environmental challenges while maintaining electrical integrity. To streamline your decision-making process, consider a checklist of essential certifications and standards:

- Environmental resistance certifications (weatherproof, explosion-proof)

- Electrical safety approvals (IEC, UL, BS)

- Material and construction compliance

- Installation and maintenance certifications

By prioritising certified and compliant products, you safeguard your investment and uphold the highest standards of electrical safety. This approach guarantees that your electrical cable joint box not only meets regulatory demands but also delivers dependable performance in demanding environments.

Supplier Selection – How to select reputable suppliers and brands

In the shadowed corridors of electrical craftsmanship, the choice of a reliable electrical cable joint box is paramount. The darkness conceals many hazards—only the seasoned know to seek out suppliers whose reputation is as unwavering as a lighthouse in a storm. Reputable brands, forged through rigorous standards, become the guardians of safety in a realm fraught with peril.

When selecting a supplier, consider their commitment to quality and certification. A trusted supplier will offer products that meet exacting standards such as IEC, UL, or local regulatory approvals. These certifications are not mere tokens; they are the seal of unwavering safety and durability, vital in both subterranean and exposed environments.

To navigate this labyrinth of options, some experts advocate a simple yet profound checklist:

- Verify the supplier’s certifications and compliance with environmental resistance standards.

- Assess their reputation for delivering durable, well-constructed electrical cable joint boxes.

- Ensure the supplier’s capacity to provide comprehensive installation accessories and technical support.

In this dark theatre of power, choosing the right supplier transforms a mere component into a steadfast guardian of your electrical domain—an unyielding sentinel against the chaos of environmental and operational threats. Only then can your installations stand resilient against the encroaching shadows of failure and hazard.

Future Trends in Cable Joint Box Technology

Innovative Materials – Emerging materials for enhanced durability and performance

As technology advances, the future of electrical cable joint box design is poised for a remarkable transformation driven by innovative materials. These emerging materials promise to enhance durability and performance, especially in demanding environments. Think lightweight composites and advanced polymers that resist corrosion, UV radiation, and temperature extremes more effectively than traditional options. Such materials could revolutionise the way we approach installation and maintenance, making these essential components more reliable over longer periods.

Incorporating new materials not only extends the lifespan of electrical cable joint boxes but also opens avenues for more compact, versatile designs. For example, some manufacturers are experimenting with nanomaterials that offer increased insulation properties while maintaining flexibility. These cutting-edge developments are set to improve environmental resistance, reduce costs, and ensure safety standards are met with greater ease. As the industry explores these frontiers, the integration of sustainable, high-performance materials will become a key trend shaping the future of electrical cable joint box technology.

Smart and Connected Boxes – Introduction to IoT-enabled cable joint boxes

The future of electrical cable joint box technology is rapidly evolving, driven by the relentless pursuit of smarter, more integrated solutions. As the industry harnesses the power of IoT-enabled systems, these smart and connected boxes are transforming traditional electrical infrastructure into responsive, data-driven networks. Imagine a scenario where your electrical cable joint box continuously monitors internal conditions—temperature, moisture levels, even cable integrity—transmitting real-time data to central management platforms. This proactive approach not only enhances safety but also predicts maintenance needs before faults manifest, drastically reducing downtime.

By integrating IoT technology, manufacturers are creating electrical cable joint boxes that are both intelligent and adaptable. These innovations facilitate remote diagnostics and automated alerts, streamlining maintenance processes and elevating reliability standards. Furthermore, the synergy of connectivity with advanced materials—such as high-performance composites—ensures these boxes withstand environmental extremes while maintaining optimal functionality. As industries embrace digitalisation, the advent of smart, connected electrical cable joint boxes signals a new epoch where efficiency and resilience are seamlessly intertwined.

Environmental Sustainability – Eco-friendly design and recyclable materials

As industries worldwide pivot towards sustainable development, the future of electrical cable joint boxes is increasingly intertwined with environmental consciousness. Innovations in eco-friendly design are not merely a trend but a necessity—arising from the urgent need to reduce carbon footprints and minimise waste. Manufacturers are now prioritising recyclable materials such as high-performance composites and biodegradable plastics, which provide robust protection while enabling circular economy principles. This shift ensures that each electrical cable joint box not only meets performance standards but also aligns with global sustainability goals.

Furthermore, the integration of environmentally sustainable materials extends the lifespan of these boxes, reducing the frequency of replacements and thereby decreasing material consumption. Some leading companies are adopting a holistic approach by implementing life cycle assessments to optimise resource utilisation from production through disposal. In practical terms, this means designing for disassembly, allowing for easier recycling at the end of the product’s life. Such initiatives underscore a broader industry realisation: durability and recyclability are the twin pillars of future-proof electrical infrastructure.

Innovative trends also include the utilisation of renewable energy in manufacturing processes, significantly lowering the environmental impact of producing electrical cable joint boxes. As the sector embraces digitalisation, eco-conscious designs are becoming more sophisticated, with some models featuring biodegradable gaskets and environmentally friendly sealants that resist environmental degradation while safeguarding internal components. These advances reflect a growing awareness that sustainable practices are as vital as technical excellence, ensuring that the electrical cable joint box remains a cornerstone of resilient, eco-efficient electrical systems.

- Designs prioritising recyclability and reuse

- Use of biodegradable and eco-friendly materials

- Implementing life cycle assessments for sustainability

- Reducing manufacturing emissions via renewable energy sources

In a world increasingly defined by environmental responsibility, the evolution of the electrical cable joint box embodies a commitment to both technological innovation and ecological stewardship. As we stand on the cusp of this green revolution, the industry’s dedication to sustainable design promises a future where robust electrical infrastructure harmonises seamlessly with our planet’s wellbeing—reminding us that progress and preservation are not mutually exclusive but profoundly interconnected.

Regulatory Developments – Upcoming standards and regulations impacting cable joint box manufacturing and use

As the world accelerates towards stricter environmental standards, the future of electrical cable joint boxes is poised for a transformative shift. Regulatory developments are increasingly targeting the sustainability and safety features of these vital components, ensuring they meet not only current demands but also anticipate future challenges. Governments and industry bodies are drafting upcoming standards that mandate enhanced environmental performance, compelling manufacturers to integrate eco-friendly materials and innovative designs.

For instance, new regulations may require that electrical cable joint boxes incorporate recyclable and biodegradable materials, aligning with global efforts to reduce plastic waste and carbon footprints. Additionally, standards concerning seismic resilience, fire safety, and moisture resistance are becoming more rigorous—pushing the envelope of what is technically feasible. An ordered list of anticipated regulatory trends might include:

- Mandatory use of environmentally sustainable materials.

- Enhanced sealing and insulation standards for outdoor and underground installations.

- Improved safety protocols for explosion-proof and hazardous area applications.

- Integration of IoT technology for real-time monitoring and diagnostics.

These evolving regulations not only influence manufacturing protocols but also guide how electrical cable joint boxes are tested and certified before reaching the field. As compliance becomes more complex, selecting products that already meet these future standards will be a key differentiator for industry stakeholders. Ultimately, regulatory progress is steering the sector towards a more resilient, eco-conscious future—one where the humble electrical cable joint box plays a starring role in sustainable infrastructure development.