Understanding Electrical Cable Fasteners

Definition and Function – What Are Electrical Cable Fasteners and How Do They Work?

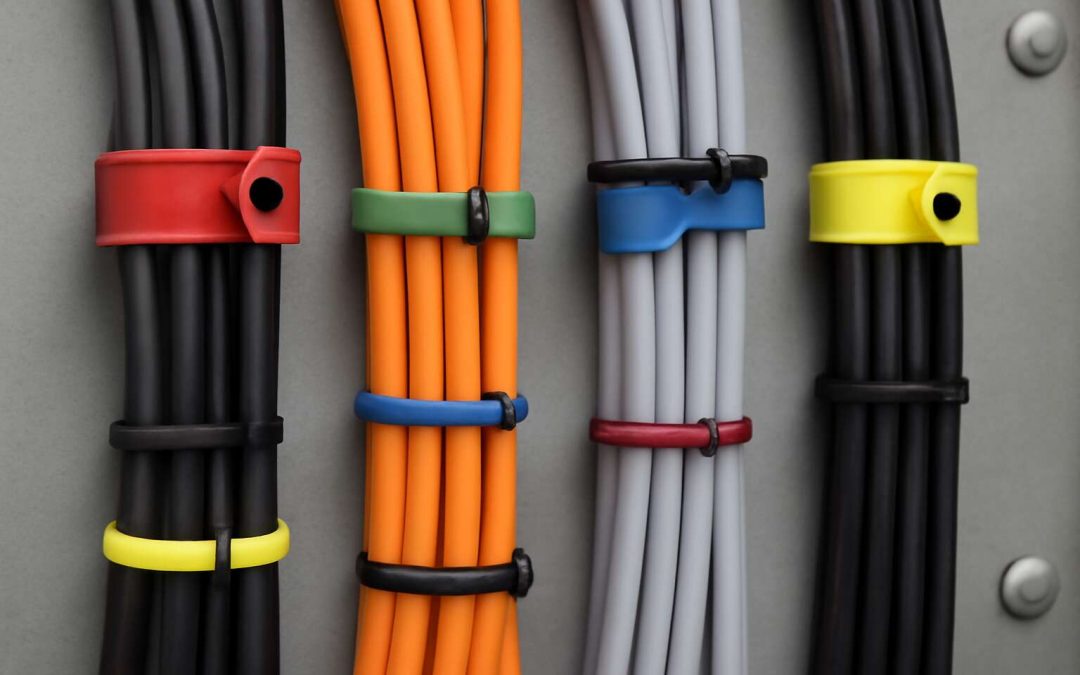

Electrical cable fasteners serve as the silent guardians of organized and secure wiring systems. Their primary function is to firmly hold electrical cables in place, preventing tangling, damage, or accidental disconnection. Imagine a complex network of cables running through a building—without reliable fasteners, chaos and safety hazards would quickly follow. These components are designed to work seamlessly within various environments, from industrial facilities to residential installations, ensuring longevity and safety.

So, what exactly are electrical cable fasteners, and how do they operate? Essentially, they are small but vital devices that anchor cables to surfaces or within conduit systems. Their role is crucial in maintaining the integrity of electrical systems, especially in high-stress conditions. By securing cables properly, they reduce strain and minimize wear, significantly extending the lifespan of wiring. For those seeking durability, selecting the right fastener often involves understanding the specific needs of the installation, such as load capacity and environmental resistance.

- Clamps

- Straps

- Cable ties

Each type of electrical cable fastener is tailored to different applications, providing flexibility and safety in complex wiring landscapes. When chosen correctly, they serve as the backbone of reliable electrical infrastructure, ensuring that cables stay in place, protected from external elements, and compliant with safety standards. The importance of these fasteners cannot be overstated—they are the unseen yet essential elements that keep electrical systems running smoothly and safely, day after day.

Types of Cable Fasteners – Common Types of Electrical Cable Fasteners and Their Uses

In the intricate ballet of wiring, where precision and durability pirouette in harmony, the role of electrical cable fasteners takes center stage. These seemingly modest components are the unsung heroes that ensure cables remain steadfast amid the chaos of bustling environments. Among the myriad types of electrical cable fasteners, each possesses a unique artistry designed for specific needs and settings.

Clamps, for instance, are the stalwart warriors in industrial installations, gripping cables tightly against surfaces, their robust design capable of withstanding high stress. Straps, with their flexibility and ease of installation, weave a protective embrace around bundles of cables, keeping them organized and reducing strain. Cable ties, perhaps the most ubiquitous of all, offer quick, reliable solutions to secure cables temporarily or permanently, their simplicity belying their critical importance.

Understanding the diverse landscape of electrical cable fasteners reveals a tapestry of solutions—ranging from the sturdy to the subtle—that underpin safety and longevity in electrical systems. Whether in sprawling factories or cozy homes, choosing the right fastener is an art that ensures cables stay in place, resilient against the tumult of time and environment.

Materials and Construction – Materials Used in Manufacturing Cable Fasteners

Electrical cable fasteners are the unsung heroes in the world of wiring, and their materials and construction are just as vital as their function. The durability, flexibility, and environmental resistance of these fasteners hinge on the materials used in their manufacture. From the rugged charm of stainless steel to the versatile nature of nylon, each material offers a distinct set of advantages tailored for specific applications.

Stainless steel, known for its corrosion resistance, is perfect for outdoor or industrial settings in South Africa where exposure to moisture and dust is relentless. Nylon, on the other hand, shines in indoor environments with its lightweight yet sturdy profile, making installation a breeze while maintaining strength. For electrical cable fasteners subjected to extreme temperatures or chemical exposure, materials like thermoplastic or even specialized composites are often employed to guarantee longevity and safety.

When selecting the right fastener, consider these key factors:

- Environmental conditions – Will it face moisture, heat, or chemicals?

- Load-bearing requirements – How much tension will it endure?

- Ease of installation – Is quick setup a priority?

Understanding the materials behind electrical cable fasteners not only enhances their application but also ensures the longevity of your electrical systems—because a fastener that can’t handle the environment is just a fancy paperweight in disguise.

Types of Electrical Cable Fasteners

Cable Clamps and Clips – Comfortable Solutions for Securing Cables

In the realm of electrical installation, the choice of cable fasteners can transform chaos into order, much like a skilled sorcerer weaving spells of stability. Among these, cable clamps and clips stand as the stalwart guardians of organized wiring systems, offering comfort and reliability for securing cables with finesse. Their versatility makes them indispensable, especially when the safety and longevity of electrical systems are paramount.

Electrical cable fasteners such as cable clamps and clips come in a myriad of designs tailored to fit various applications. From simple plastic clips to robust metal clamps, each type offers unique advantages. For instance, some clips are designed with adjustable features to accommodate different cable diameters, while others provide a fixed, snug fit that prevents movement and wear over time. The choice of material—be it nylon, stainless steel, or zinc-plated steel—further enhances their durability in diverse environments, from damp basements to outdoor installations.

To ensure seamless installation, many manufacturers now offer cable fasteners that combine ease of use with a secure grip, reducing installation time and minimizing the risk of damage. Whether you’re securing cables along walls or suspending them from ceilings, these fasteners provide a comfortable, dependable solution that keeps electrical systems tidy and safe. With the right cable clamp or clip, electricians can transform a tangled mess into a masterpiece of order and safety!

Cable Ties and Zip Ties – Versatile and Cost-Effective Fastening Options

In the intricate dance of electrical installation, the choice of electrical cable fasteners can make all the difference between chaos and order. Among the most versatile and cost-effective options are cable ties and zip ties—simple yet remarkably powerful tools that transform tangled wiring into a symphony of precision. Their ability to secure multiple cables simultaneously not only streamlines the installation process but also enhances safety by preventing accidental disconnections or damage.

These fastening marvels come in a variety of materials, including nylon and reinforced plastics, designed to withstand the rigors of diverse environments—from humid basements to outdoor settings. The beauty of cable ties and zip ties lies in their adaptability; whether bundling cables in a server room or securing wiring along a conduit, they offer a seamless solution. They are available in different sizes, ensuring a snug fit for every application—making them the go-to choice for electricians seeking reliability and efficiency in their work.

- Affordability and ease of use make cable ties a staple in every electrician’s toolkit.

- Their quick installation process reduces labor time, especially in large-scale projects.

- Reusability options are available, adding an extra layer of sustainability to electrical work.

Strain Relief Connectors – Preventing Damage and Maintaining Safety

In the shadowy world of electrical installations, strain relief connectors stand as silent guardians—preventing cable damage before it can strike. These specialized electrical cable fasteners absorb the tension and movement that could otherwise compromise wiring integrity, especially in high-stress environments. Without proper strain relief, cables can fray, loosen, or even cause dangerous shorts, risking safety and costly repairs.

To combat this, electricians often turn to robust solutions like cable glands, cable clamps, and specially designed strain relief connectors. These fasteners are engineered to lock cables firmly in place, dispersing mechanical stress evenly and maintaining the system’s safety. For added security, some models feature flexible designs that adapt to various cable diameters, ensuring a snug fit every time. Their durability is essential in South Africa’s diverse conditions, from humid coastal regions to arid inland deserts.

When selecting electrical cable fasteners, it’s crucial to consider the environment and the specific needs of each project. A well-chosen strain relief connector not only preserves the longevity of your wiring but also safeguards everyone who relies on the electrical system. It’s a small component with a mighty impact—one that keeps the electrical dance in perfect harmony and prevents chaos from creeping into the wires.

Saddles and Mounting Brackets – For Fixed Supports and Heavy-Duty Applications

When it comes to securing cables in demanding environments—be it a bustling Johannesburg construction site or a remote coastal installation—reliable support is paramount. Enter the humble yet indispensable electrical cable fasteners, particularly saddles and mounting brackets. These components are the unsung heroes of fixed supports and heavy-duty applications, providing a steadfast grip that withstands the rigors of vibration, temperature fluctuations, and mechanical stress.

Saddles and mounting brackets are designed with precision, often crafted from durable materials like galvanized steel or sturdy plastics to ensure longevity. They cradle cables securely, preventing movement that could lead to wear and tear or accidental disconnection. For larger, high-voltage systems, robust fasteners are essential to distribute weight evenly and maintain system integrity. In such scenarios, selecting the right fastening solution can mean the difference between a safe, efficient installation and a costly, hazardous failure.

In some cases, a

- fixed support

- heavy-duty bracket

approach is not just recommended but mandatory—especially when cables run across expansive distances or through challenging terrains. These fasteners facilitate easy maintenance and upgrades, making them a staple in the toolbox of South African electricians who value durability and precision. After all, a well-supported cable system is a silent testament to professionalism, quietly safeguarding lives and investments alike.

Cable Staples and Pin Fasteners – Easy Installation in Wood and Insulated Surfaces

When it comes to securing electrical cables, simplicity can be a game-changer—enter cable staples and pin fasteners. These unassuming heroes excel at turning a tangled mess into a neat, organized system—especially when working with wood or insulated surfaces. Their quick and fuss-free installation means you won’t need a PhD in engineering to keep your cables in line.

Cable staples are designed for straightforward installation. Simply hammer them into place, and voilà—your cables are snugly held without fuss. Pin fasteners, on the other hand, are perfect for more delicate surfaces or when you need a bit more finesse. They work by pinning the cable directly, often using a nail or pin that locks into a durable plastic or metal body. This duo makes wiring jobs across South Africa’s diverse environments—whether a cozy home or a sprawling industrial site—less of a headache.

To enhance efficiency, some professionals prefer to use electrical cable fasteners that combine both staples and pins, allowing flexibility based on the surface and load. This versatility ensures that cables stay in place, preventing accidental disconnection and reducing wear over time. Plus, with their lightweight design, they’re a cost-effective way to keep your wiring tidy and compliant with safety standards.

So, whether you’re running cables along a wooden wall or securing insulation-covered wiring, cable staples and pin fasteners are your trusty sidekicks—making electrical installation both a breeze and a testament to good craftsmanship. After all, a well-fastened cable system isn’t just neat; it’s a safeguard against future mishaps, and a subtle nod to professional pride.

Choosing the Right Electrical Cable Fasteners

Considerations for Selection – Factors Such as Cable Size, Material, and Environment

Choosing the right electrical cable fasteners isn’t just about grabbing the first shiny clip you see. It’s a strategic dance—matching the fastener to the cable size, material, and environment can make all the difference between a tidy setup and a future safety nightmare. Did you know that improper fastening can lead to cable wear and even electrical faults? That’s where understanding the nuances becomes essential.

Firstly, consider the cable size—oversized fasteners can crush or damage delicate insulation, while undersized ones might slip, causing sagging or strain. Environmentally, if the installation is outdoors, corrosion-resistant materials such as stainless steel or UV-stable plastics become your best friends. For indoor applications, standard plastic clips often suffice but don’t underestimate the importance of secure mounting points. Remember, a well-chosen electrical cable fastener not only ensures safety but also prolongs the lifespan of your wiring system.

Compatibility with Cable Types – Different Fasteners for Coaxial, Data, and Power Cables

Choosing the right electrical cable fasteners is essential for ensuring the longevity and safety of your wiring, especially when dealing with different types of cables. Coaxial, data, and power cables each have unique requirements, and selecting compatible fasteners can prevent costly damage down the line.

For coaxial cables, which are delicate and often used for high-frequency signals, soft and non-abrasive fasteners are crucial. Conversely, power cables demand sturdy, high-tensile fasteners capable of supporting heavier loads. Data cables, with their fine insulation, benefit from lightweight clips that avoid compression damage.

In some cases, specialized fasteners like cable clips with adjustable clamps or mounting brackets tailored for specific cable types can make installation smoother and more reliable. Remember, compatibility isn’t just about fit; it’s about maintaining the integrity of the cable’s insulation and shielding, which ultimately safeguards your entire electrical system.

Load and Stress Requirements – Ensuring Fasteners Can Handle Mechanical Stress

In the intricate web of electrical systems, fasteners are often overlooked yet play a pivotal role in safeguarding the integrity of your wiring. The load and stress requirements placed on electrical cable fasteners are critical factors that determine the durability and safety of the entire installation. When cables are subjected to constant tension, vibration, or environmental forces, fasteners must possess the strength to withstand these pressures without compromising insulation or shielding.

Choosing fasteners that can handle the specific mechanical stresses your cables will encounter is not merely a matter of convenience; it is an ethical obligation to ensure safety. For high-tensile power cables, robust options like heavy-duty clamps or mounting brackets provide the support needed to prevent sagging or damage. Conversely, lightweight solutions such as cable ties work well in low-stress environments, maintaining order without adding unnecessary weight or rigidity.

It’s essential to match the fastener’s load capacity with the intended application. An overlooked detail can lead to catastrophic failure, risking both property and lives. Remember, quality electrical cable fasteners are an investment in long-term reliability — a silent guardian in the complex dance of electricity. When stress surpasses the fastener’s capacity, the entire system becomes vulnerable, making it imperative to select the right fastener for the job.

Installation Best Practices

Proper Fastening Techniques – Ensuring Secure and Safe Cable Management

In the realm of electrical cable fasteners, mastery of installation best practices transforms chaotic wiring into a symphony of order and safety. When fastening cables, precision and care are paramount—each fastener must cradle the cable securely without compromising its integrity. A well-placed fastener acts as a guardian, preventing unnecessary stress and potential damage that could lead to costly repairs or hazards.

To ensure a secure and safe cable management system, consider the environment and cable load. Proper fastening techniques involve choosing the right type of electrical cable fasteners that match the cable size and material. For instance, using cable clips designed for specific cable diameters ensures snug fitment, reducing movement and wear over time. Additionally, spacing fasteners appropriately—typically every 30 to 50 centimeters—maintains optimal support and minimizes sagging.

It’s also essential to avoid overtightening, which can crush or deform the cable insulation, risking electrical faults. Instead, gentle but firm pressure is key. When installing, always verify that fasteners do not pinch or damage the cable, especially in environments with vibrations or mechanical stress. These practices culminate in a cable management system that is not only efficient but resilient, standing the test of time and environmental challenges.

Avoiding Damage to Cables – Tips to Prevent Pinching, Crimping, or Cutting

When it comes to electrical cable fasteners, a little finesse goes a long way—especially if you want cables to stay put and avoid the chaos of a wiring spaghetti. Over-tightening fasteners can turn a sleek setup into a disaster zone, crushing insulation and risking costly faults. The trick is to apply just enough pressure—firm, but gentle—so the cable remains supported without damage.

To prevent pinching, crimping, or cutting, always match the fastener to the cable’s diameter and material. Using the wrong size or type can lead to deformation or insulation breaches, inviting potential electrical hazards. For added safety, consider implementing a few simple best practices:

- Ensure fasteners are spaced every 30 to 50 centimeters for optimal support.

- Inspect for signs of deformation or pinching after installation, especially in environments with vibrations or movement.

- Avoid placing fasteners directly on sharp bends or edges that could cut into the cable insulation over time.

Remember, the goal with electrical cable fasteners is to keep the cables secure and protected without turning into a DIY nightmare. Proper installation techniques—combined with thoughtful selection—are the secret ingredients for a safe, durable wiring system that can withstand the rigours of everyday use in South Africa’s diverse environments. So, fasten wisely, and your cables will thank you for it!

Compliance with Electrical Codes – Meeting Industry Standards and Regulations

Compliance with electrical codes is the backbone of a safe and reliable wiring system. In South Africa, where diverse environments—from bustling urban centers to remote rural homesteads—demand tailored solutions, adhering to industry standards isn’t just a legal obligation—it’s a commitment to safety and durability. Proper installation of electrical cable fasteners ensures that cables are secured according to strict regulations, reducing the risk of faults, fires, or costly repairs.

To meet these standards, it’s essential to select the right fasteners for the specific environment and cable type. For instance, using weather-resistant cable ties in outdoor applications or heavy-duty mounting brackets in industrial settings helps maintain safety and functionality. Local electrical codes often specify spacing requirements and load capacities for fasteners, which should always be followed. An ordered approach—such as:

- Assessing cable load and environmental conditions,

- Choosing the appropriate fastener material,

- Ensuring proper installation techniques—

can make all the difference in achieving compliance. Regular inspection of installed cable fasteners, especially in vibratory or high-traffic areas, is equally vital. This proactive approach not only preserves the integrity of the wiring but also guards against potential hazards lurking beneath the surface. When it comes to electrical cable fasteners, respecting industry standards isn’t just compliance—it’s a heartfelt promise to keep everyone safe and connected in South Africa’s vibrant communities. Properly fastened cables ensure that the heartbeat of everyday life—electricity—flows smoothly and securely, no matter the terrain or challenge.

Benefits of Using High-Quality Electrical Cable Fasteners

Enhanced Safety and Reliability – Reducing the Risk of Damage and Electrical Failures

In a world where electrical failures can lead to costly downtime or even dangerous hazards, the importance of high-quality electrical cable fasteners cannot be overstated. These small but mighty components are the unsung heroes in ensuring enhanced safety and reliability in electrical systems. By choosing superior fasteners, you significantly reduce the risk of damage to cables caused by vibration, tension, or environmental stressors, which can otherwise culminate in shorts or fire hazards.

Opting for durable, well-engineered electrical cable fasteners means your wiring remains secure and intact, even under demanding conditions. This steadfast anchoring prevents accidental disconnections and minimizes the wear and tear on cables. A reliable fastening system ensures that electrical connections stay consistent, safeguarding your infrastructure from failures that could disrupt operations or compromise safety standards. When safety is paramount — whether in industrial settings or residential installations — the right fasteners are the backbone of a resilient electrical network.

Organization and Aesthetics – Creating a Neat and Professional Appearance

In the realm of electrical infrastructure, a meticulous eye for detail can transform chaos into clarity. High-quality electrical cable fasteners are the artisans behind this transformation, elevating organization and aesthetics to new heights. When cables are secured with precision, the visual harmony of the installation is undeniable, creating a professional appearance that commands respect and confidence.

Imagine a workspace where every cable whispers order, not disorder. Well-chosen electrical cable fasteners do just that—streamlining wiring pathways and ensuring that each cable aligns seamlessly with its neighbors. This not only enhances the visual appeal but also simplifies future maintenance, reducing downtime and safeguarding your investment. For businesses and homeowners alike, an organized setup reflects a commitment to excellence and safety.

Moreover, the array of fastener options available allows for tailored solutions that fit the unique demands of each environment. From sleek cable clips to heavy-duty mounting brackets, these components help craft a tidy, professional look that leaves a lasting impression. After all, an orderly installation isn’t just about beauty; it’s a testament to safety and enduring quality. When it comes to electrical cable fasteners, aesthetics and organization are the guardians of a resilient and visually striking system.

Ease of Maintenance and Upgrades – Simplifying Future Modifications and Repairs

High-quality electrical cable fasteners do more than just keep wires in check; they fundamentally ease the burden of maintenance and future upgrades. When cables are secured with precision, accessing them for repairs or modifications becomes a straightforward task rather than a frustrating scavenger hunt. This not only saves time but also minimizes disruption, ensuring your electrical system remains resilient and efficient.

Choosing the right fasteners means selecting components designed to withstand mechanical stress while maintaining a firm grip. For example, robust cable clips and mounting brackets allow for quick adjustments without risking damage to the cables. As a result, your setup remains tidy and accessible, making troubleshooting a breeze and upgrades less invasive. In environments where safety and reliability are paramount, this streamlined approach to cable management is invaluable.

Additionally, the versatility of electrical cable fasteners—ranging from simple cable ties to heavy-duty saddles—facilitates seamless integration into any project. This flexibility ensures that whether you’re working on a commercial installation or a residential upgrade, your cables are held securely and organized for easy access. Such thoughtful fastening solutions turn complex wiring systems into accessible, manageable networks, proving that quality fasteners are truly the backbone of efficient electrical infrastructure.

Where to Buy Electrical Cable Fasteners

Online Retailers and Suppliers – Trusted Sources for Wide Selection and Bulk Purchasing

In a landscape where precise cable management can mean the difference between safety and chaos, sourcing high-quality electrical cable fasteners becomes paramount. South African retailers and online suppliers have recognized this demand, offering an extensive array of options tailored to diverse needs—from delicate data cables to heavy-duty power lines. The challenge often lies in navigating the myriad of choices, but trusted online retailers streamline this process, providing detailed specifications and bulk purchasing options that cater to both small projects and large-scale installations.

For those seeking reliable sources, consider exploring well-established platforms such as:

- South African electrical supply e-commerce sites, renowned for their comprehensive range of electrical cable fasteners

- Global industrial suppliers with a trusted local presence, offering bulk purchase discounts and fast delivery

- Specialist online marketplaces that feature verified vendors ensuring product quality and compliance with industry standards

These sources not only facilitate the procurement of diverse fasteners—such as cable clips, ties, and mounting brackets—but also support customization for specific environments, ensuring optimal performance and safety. Whether you need a handful of cable ties or a pallet of heavy-duty clamps, reliable online retailers provide the convenience and peace of mind that every project demands.

Specialty Electrical Stores – Expert Advice and In-Store Support

When it comes to sourcing top-tier electrical cable fasteners in South Africa, specialty electrical stores stand out as hubs of expertise and personalized service. These stores are not just retail outlets; they are knowledge centers where professionals and DIY enthusiasts alike find tailored advice on selecting the perfect fasteners for their projects. Unlike general hardware shops, specialized outlets often carry an extensive range of electrical cable fasteners that meet strict industry standards, ensuring safety and durability.

Walking into one of these stores, you’ll find a knowledgeable staff ready to assist with complex queries—whether you’re securing delicate data cables or heavy-duty power lines. The staff can help you evaluate factors such as cable size, material compatibility, and environmental conditions—crucial elements for choosing the right fastener. Many specialty electrical stores also offer in-store support, guiding you through proper fastening techniques to prevent damage and ensure compliance with electrical codes.

Some stores feature dedicated sections for:

- Cable clips and mounting brackets

- Zip ties and cable ties

- Strain relief connectors

This hands-on approach simplifies the selection process, making sure every fastener fits the specific application. For those seeking reliability, local specialist electrical stores provide not only expert advice but also the reassurance of quality and compliance that online options sometimes lack. When precision matters, trusting a specialist ensures your electrical cable fasteners will perform flawlessly—every time.

Bulk Buying Tips – Cost Savings and Inventory Management

Where to Buy Electrical Cable Fasteners in Bulk: Cost Savings and Inventory Management

Navigating the labyrinth of electrical supplies in South Africa can be a daunting task, especially when it comes to sourcing electrical cable fasteners in bulk. The savvy buyer understands that bulk purchasing is not merely about securing a bargain but also about streamlining inventory management and ensuring project continuity.

Opting for reputable online retailers or trusted electrical suppliers often yields the dual benefit of a wide selection and competitive pricing. When you purchase in large quantities, you unlock significant cost savings—reducing the per-unit expense and increasing your project’s overall budget efficiency.

To maximize these benefits, consider establishing relationships with local distributors who understand the nuances of South African electrical standards. An ordered list of tips might include:

- Assess your typical project needs to determine the optimal quantity of electrical cable fasteners.

- Compare prices and delivery times across multiple suppliers to find the best value.

- Verify the quality and compliance standards of the fasteners—after all, cheap fasteners can be costly in the long run.

- Maintain an organized inventory system to prevent overstocking or shortages, which can delay work or inflate storage costs.

Remember, bulk buying is not just about discounts; it’s about strategic procurement that balances cost, quality, and readiness. Whether you’re outfitting a sprawling construction site or a series of maintenance projects, choosing the right supplier for electrical cable fasteners ensures that you’ll always be prepared to wire with confidence—without breaking the bank.