Understanding 3 Core 4mm Electrical Cables

Definition and Basic Features – Explaining what a 3 core 4mm electrical cable is and its main characteristics

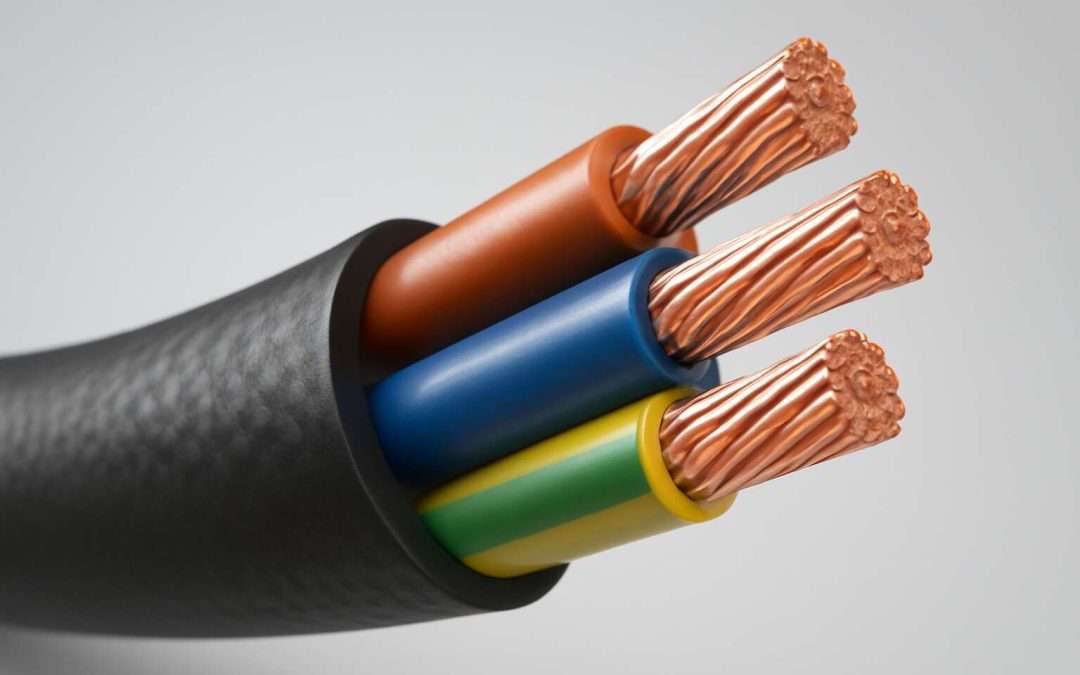

In the realm of electrical wiring, few components underscore safety and efficiency quite like the electrical cable 3 core 4mm. This type of cable is meticulously designed to cater to a variety of domestic and commercial applications, blending robustness with flexibility. Its defining feature is the three core conductors, each insulated and colour-coded, enabling clear identification and safe handling during installation.

What sets the electrical cable 3 core 4mm apart is its core size—4mm²—offering a balanced combination of current capacity and ease of manoeuvrability. This makes it ideal for powering lighting circuits, appliances, or even more complex setups where reliable conduction is paramount. The core features include high-quality copper conductors, durable insulation materials, and a protective outer sheath, all engineered to withstand environmental stresses and minimise power loss over distance.

For those seeking a versatile and dependable wiring solution, understanding the fundamental features of the electrical cable 3 core 4mm is essential. Its design reflects a harmony of safety standards and practical functionality, making it a staple in modern electrical infrastructure.

Components of a 3 Core 4mm Cable – Details about the conductors, insulation, and protective sheath

At the heart of every reliable electrical installation lies the intricate craftsmanship of the electrical cable 3 core 4mm. Its components are thoughtfully engineered to deliver safety, durability, and seamless conductivity. The core of this cable comprises high-quality copper conductors, renowned for their exceptional electrical performance and flexibility. These conductors are meticulously insulated to prevent any accidental contact or short circuits, ensuring safety during installation and operation.

The insulation material, typically a durable PVC or cross-linked polyethylene, acts as a protective barrier against environmental stressors such as moisture, heat, and mechanical wear. This ensures the longevity of the cable, even in demanding conditions. Surrounding the insulated cores is a robust outer sheath that provides additional safeguarding, shielding the internal components from abrasions, chemicals, and physical damage. This layered construction exemplifies a perfect harmony between resilience and adaptability—traits that make the electrical cable 3 core 4mm indispensable in modern wiring systems.

To better appreciate its versatility, consider the following key components of the electrical cable 3 core 4mm:

- High-quality copper conductors for optimal current flow

- Insulation materials like PVC or cross-linked polyethylene for safety and durability

- Protective outer sheath to resist environmental and mechanical stresses

Each element works synergistically to ensure that the electrical cable 3 core 4mm not only meets rigorous safety standards but also provides a flexible, dependable solution for a myriad of electrical applications. Its carefully crafted construction reflects a commitment to excellence, offering both peace of mind and performance that stand the test of time.

Common Uses and Applications – Typical scenarios in residential, commercial, and industrial settings

Electrical cable 3 core 4mm is the unsung hero behind countless modern electrical systems, quietly powering homes, businesses, and factories with unwavering reliability. Its versatility makes it an essential component across a spectrum of applications, blending safety with efficiency. In residential settings, it often appears in wiring for lighting circuits and power outlets, seamlessly connecting switches and appliances while maintaining safety standards.

Commercial and industrial environments, however, reveal even greater utility for the electrical cable 3 core 4mm. It is frequently employed in complex wiring configurations, such as connecting motor controls, distribution boards, or large-scale lighting systems. Its robust construction ensures resilience against mechanical stress and environmental factors, making it ideal for demanding locations.

In fact, the adaptability of this cable is exemplified by its widespread use in:

- Lighting installations in both domestic and commercial buildings

- Power supply wiring for machinery and industrial equipment

- Connecting electrical panels in HVAC systems

- Wiring for outdoor fixtures where weather resistance is paramount

Whether in a cosy home or an expansive factory, the electrical cable 3 core 4mm remains a dependable choice. Its capacity to handle substantial current loads while offering durability underpins its reputation as a vital element in diverse electrical landscapes, ensuring seamless connectivity and safety at every turn.

Technical Specifications of 3 Core 4mm Cables

Cable Dimensions and Size – Understanding the 4mm core size and its implications

In the realm of electrical engineering, understanding the dimensions of cables is fundamental to ensuring safety and efficiency. The 4mm core size in a 3 core 4mm electrical cable is more than just a measurement; it signifies a carefully engineered balance between flexibility and capacity. This diameter allows for a robust conductor that can handle substantial current loads, making it suitable for diverse applications, from household wiring to industrial installations.

When delving into the technical specifications, one must consider that the 4mm core diameter directly influences the cable’s current-carrying capacity and voltage drop. A thicker core typically means less resistance, which translates to reduced heat generation and enhanced durability over time. This characteristic is vital in settings where reliability is paramount. Moreover, the dimensions of the cable impact its overall size and flexibility, factors that are critical during installation and maintenance.

Understanding the precise dimensions of a 3 core 4mm electrical cable helps professionals select the correct cable for specific tasks. For instance, in residential wiring, the 4mm core size ensures sufficient power delivery without excessive bulk. Conversely, in industrial environments, it supports higher power demands with minimal risk of overheating. Recognising these nuances underscores the importance of accurate cable sizing for enduring performance and safety.

Current and Voltage Ratings – Maximum load capacities and electrical standards

The true power of an electrical cable 3 core 4mm lies in its ability to withstand demanding loads without faltering. Its current and voltage ratings are vital benchmarks that determine safety and performance—parameters that should never be overlooked. When selecting a cable, understanding these specifications can mean the difference between a reliable installation and a potential hazard.

Typically, a 3 core 4mm electrical cable is rated to carry a maximum current of around 25-32 amps, depending on installation conditions and thermal insulation. This capacity aligns with UK electrical standards, which emphasise safety and efficiency. The voltage rating generally peaks at 450/750V, making it suitable for most domestic and commercial applications. These ratings ensure the cable can handle high power demands, whether powering lighting, appliances, or industrial machinery.

- Maximum Load Capacity: The 4mm core size supports substantial current loads, making it ideal for circuits where high power is essential.

- Standards Compliance: It adheres to UK electrical standards, including BS 6004 and IEC regulations, ensuring safety and durability.

By understanding these technical specifications, professionals can confidently deploy an electrical cable 3 core 4mm that not only meets regulatory requirements but also enhances the longevity of the electrical system. The interplay between current capacity and voltage rating underscores the importance of precise cable selection in safeguarding both property and lives.

Material Composition – Types of conductors (copper or aluminium), insulation materials, and outer sheathing

The heart of any robust electrical installation beats strongest with the right choice of cable materials. A top-tier electrical cable 3 core 4mm isn’t just about its size; it’s about the quality and composition of its components that determine its endurance and safety. The conductors, insulation, and outer sheathing work together to withstand demanding environments and high power loads, ensuring longevity and reliability.

Most commonly, the conductors within an electrical cable 3 core 4mm are crafted from high-purity copper, renowned for its excellent conductivity and flexibility. Copper’s superior electrical properties make it the preferred choice for most installations, offering minimal resistance and efficient current transfer. Alternatively, some cables feature aluminium conductors, which are lighter and more cost-effective, though they require careful handling due to lower conductivity.

Insulation materials are equally critical. They must resist heat, moisture, and mechanical stress. Polyvinyl chloride (PVC) remains the standard, providing excellent insulation and fire resistance. For more demanding environments, fire-retardant or halogen-free variants are available, boosting safety standards further. The outer sheathing, often made from tough PVC or rubber compounds, shields the inner components from physical damage and environmental factors, ensuring the cable’s integrity over time.

Understanding these material nuances allows professionals to select the perfect electrical cable 3 core 4mm for any project—be it domestic wiring or industrial power distribution. The interplay of conductor type, insulation, and sheathing not only influences performance but also aligns with compliance standards, safeguarding both property and lives in the process.

Advantages and Benefits of Using 3 Core 4mm Cables

Safety and Compliance – Meeting electrical safety standards and preventing hazards

Safety and compliance are the bedrock of electrical installations, especially when it involves an electrical cable 3 core 4mm. These cables are designed with rigorous standards in mind, ensuring that they meet essential electrical safety standards and prevent hazards such as short circuits, overheating, and electrical fires. When properly installed, a 3 core 4mm cable not only provides reliable power delivery but also contributes to a safer environment for homes and businesses alike.

The inherent construction of a 3 core 4mm cable emphasises durability and resilience. Its robust insulation and protective sheath serve as barriers against mechanical damage and environmental factors, reducing the risk of faults. Moreover, compliance with national and international safety standards offers peace of mind, knowing that your electrical system adheres to the highest regulatory requirements. In a world where safety cannot be compromised, choosing a quality electrical cable 3 core 4mm is a critical decision—one that safeguards lives while ensuring uninterrupted operation.

Flexibility and Durability – Ease of installation and resistance to environmental factors

In the intricate dance of electrical wiring, flexibility and durability are often overlooked but fundamentally vital. The electrical cable 3 core 4mm stands as a testament to resilience, designed not just to meet standards but to surpass expectations in demanding environments. Its construction allows for ease of installation, reducing labour time and the risk of errors that can compromise safety or performance.

Moreover, the resistance of this cable to environmental factors such as moisture, temperature fluctuations, and mechanical stress makes it an ideal choice for diverse settings. Whether installed in a bustling commercial building or a remote industrial site, the robustness of a 3 core 4mm cable ensures longevity and consistent performance. Its flexible nature allows it to navigate tight corners and complex routing with minimal fuss, saving time and effort during installation.

- Ease of handling during installation

- Resilience against environmental stressors

- Compatibility with various electrical systems and configurations

This combination of flexibility and durability, intrinsic to the electrical cable 3 core 4mm, exemplifies a commitment to safety, efficiency, and longevity. It’s not merely about powering devices; it’s about creating a reliable foundation that withstands the test of time and human intervention. When choosing cable for your project, recognising these benefits ensures a future free from unexpected faults and hazards—an investment in peace of mind that truly pays off.

Efficiency and Performance – Optimal electrical performance and longevity

When it comes to ensuring optimal electrical performance, the choice of cable can make all the difference. The electrical cable 3 core 4mm is renowned for its exceptional capacity to deliver reliable power with minimal loss, translating into increased efficiency across various applications. Its sturdy construction and high-quality materials guarantee longevity, reducing the need for frequent replacements and maintenance. This durability not only enhances safety but also ensures consistent performance over time, even in demanding environments.

One of the greatest advantages of the electrical cable 3 core 4mm is its ability to handle substantial current loads without overheating, making it suitable for both residential and industrial projects. Its design allows for smooth, uninterrupted power flow, preventing voltage drops that can compromise connected devices. The robustness of this cable means it withstands environmental stressors such as temperature fluctuations and mechanical stress, maintaining its integrity and performance for years to come.

Incorporating the electrical cable 3 core 4mm into your wiring system offers tangible benefits, including:

- Enhanced safety due to high-quality insulation and protective sheathing

- Reduced energy wastage through efficient conductivity

- Versatility in various electrical configurations and systems

Choosing the right cable isn’t just about meeting standards; it’s about investing in a dependable, high-performance component that powers your future with unwavering stability and efficiency.

Factors to Consider When Choosing 3 Core 4mm Cables

Installation Environment – Indoor vs outdoor, exposure to elements

Choosing the right electrical cable 3 core 4mm isn’t just about matching the size; it’s about understanding the environment where it will serve. Indoor installations typically demand cables with enhanced flexibility and fire-resistant insulation to navigate tight spaces and minimise safety risks. Conversely, outdoor applications pose a different challenge—exposure to weather, UV rays, and moisture can accelerate wear and compromise safety if the cable isn’t appropriately rated.

In outdoor settings, selecting a cable with a robust outer sheath that offers resistance to elements is crucial. For example, a weatherproof or UV-resistant outer layer ensures longevity and maintains electrical safety standards. On the other hand, indoor environments often require cables that are easier to handle and install, with materials that prevent overheating and meet strict safety regulations.

- Assess exposure to elements: Will the cable be protected or exposed?

- Determine environmental factors: Will it face moisture, UV, or physical stress?

- Evaluate safety standards: Does the cable meet local electrical safety requirements?

Understanding these factors ensures that the chosen electrical cable 3 core 4mm not only performs optimally but also guarantees safety and durability in its designated environment. The right choice hinges on a careful balance of environmental exposure and compliance, transforming a simple cable selection into a key component of a secure electrical system.

Electrical Load Requirements – Assessing power needs and future scalability

Understanding your electrical load requirements is not merely about meeting current demands; it’s about foreseeing the unseen forces that will test your system’s resilience over time. The choice of an electrical cable 3 core 4mm must be rooted in a deep comprehension of power needs—both now and in the foreseeable future. When planning an installation, consider the potential for expansion or increased load, which could strain the cable’s capacity and compromise safety.

Assessing these requirements involves evaluating the anticipated electrical draw and ensuring the cable’s current and voltage ratings can handle the load without overheating or degrading. A misjudgment here might seem trivial but can lead to catastrophic failures—an unthinkable outcome in any setting. For this reason, it’s wise to incorporate a margin for future scalability, especially when dealing with critical or evolving infrastructure.

- Calculate the current load in amperes based on appliances and equipment.

- Review the maximum voltage the cable can sustain without compromise.

- Determine the potential for load increases over time, and select a cable with a slightly higher capacity to accommodate growth.

The balance between current needs and future expansion underscores the essence of selecting the right electrical cable 3 core 4mm. It’s a careful dance—one that demands foresight, precision, and an understanding that every detail, no matter how small, weaves into the fabric of a safe, enduring electrical system.

Regulatory Standards and Certifications – Ensuring compliance with local and international codes

In the realm of electrical installation, compliance isn’t just a guideline—it’s the beacon that ensures safety and longevity. When selecting an electrical cable 3 core 4mm, understanding the regulatory standards and certifications is paramount. These standards serve as the invisible threads weaving safety, reliability, and performance into your project, whether it’s a domestic setup or a sprawling industrial network.

National and international codes, such as BS (British Standards) or IEC (International Electrotechnical Commission) certifications, act as the gold standard for quality assurance. Ensuring your cable meets these criteria is not merely bureaucratic; it is a safeguard against potential hazards. To navigate this complex landscape, consider verifying:

- Compliance with local electrical safety standards

- Recognition of recognised certifications such as CE, UKCA, or ISO standards

- Manufacturers’ adherence to rigorous testing regimes

Choosing a cable that bears these marks of certification guarantees that your electrical cable 3 core 4mm has been scrutinised for durability, safety, and environmental resilience. It transforms the selection process from guesswork into a confident stride, knowing that every metre of cable adheres to the highest standards of compliance and quality.

Installation Tips and Best Practices

Proper Handling and Unloading – Safe procedures during transportation and storage

Embarking on the journey of installing an electrical cable 3 core 4mm requires more than just technical know-how; it demands a reverence for safety and precision. Proper handling during transportation and storage is paramount to maintaining the integrity of these vital conduits of power. A well-preserved cable ensures optimal performance, longevity, and safety in the environment where it will serve.

During unloading, always wear protective gloves and use suitable lifting equipment to avoid undue stress on the cable’s insulation and cores. Store the electrical cable 3 core 4mm in a dry, cool area, away from direct sunlight and chemical exposure, which could compromise its durability. To prevent kinks or damage, avoid stacking heavy loads on top of the cable reels and keep them on stable, flat surfaces.

When preparing for installation, follow these safe procedures:

- Inspect the cable thoroughly for any signs of damage or wear.

- Unroll the cable carefully, maintaining gentle tension to prevent internal conductor breakage.

- Use appropriate tools designed for electrical work to cut and strip the cable, avoiding unnecessary stress on the insulation.

Adhering to these best practices not only safeguards the integrity of the electrical cable 3 core 4mm but also ensures compliance with safety standards and smooth, trouble-free installation. Remember, safe handling during transportation and storage is the foundation of a reliable electrical system that stands the test of time!

Wiring Techniques – Best practices for securing and connecting cables

In any electrical installation, precision and adherence to best practices can mean the difference between a safe, reliable system and potential hazards. When working with an electrical cable 3 core 4mm, the importance of correct wiring techniques becomes even more critical. Proper securing and connecting of the cable not only optimise performance but also extend its lifespan in demanding environments.

To ensure a seamless connection, start by carefully stripping the insulation, avoiding damage to the conductors. Use specialised tools designed for electrical work to maintain the integrity of the cable’s internal structure. When connecting the cores, follow a consistent colour code and ensure each conductor is securely fastened to its terminal. Loose connections are a common culprit in electrical faults, so double-check each point of contact.

Securing the cable properly is equally essential. Use clamps or cable ties to fix the electrical cable 3 core 4mm in place, reducing strain and preventing movement that could lead to wear over time. Additionally, keep the cable away from sharp edges or sources of heat, which could compromise insulation. For outdoor or exposed environments, additional protective measures—such as conduit or trunking—are advisable to shield the cable from environmental damage.

For complex installations, consider following this simple approach:

- Secure the cable at regular intervals to prevent sagging or undue stress.

- Ensure all connections are tight and free of corrosion.

- Utilise appropriate connectors and accessories recommended for a 3 core 4mm electrical cable.

By meticulously applying these wiring techniques, professionals can ensure that the electrical cable 3 core 4mm performs optimally, delivering power safely and efficiently for years to come. Every detail matters when creating a system that balances functionality with safety—there’s no room for compromise in the world of electrical installation.

Troubleshooting Common Issues – Identifying and resolving installation problems

In the labyrinth of modern electrical systems, even the smallest oversight can ripple into significant hazards. The installation of an electrical cable 3 core 4mm demands not only technical precision but an almost intuitive understanding of its intricate behaviour under varying conditions. When troubleshooting common issues, recognising the subtle signs of stress or wear — such as unexpected heat or minor discolouration — can preempt catastrophic failures. Such anomalies often point to loose connections or compromised insulation, which, if left unaddressed, threaten both safety and performance.

To diagnose effectively, follow a methodical approach. First, examine every connection point, ensuring tight, corrosion-free contact. If persistent faults occur, inspecting the cable’s pathway for strain or abrasion can reveal hidden vulnerabilities. Sometimes, simple measures like repositioning or reinforcing the cable at strategic intervals (

- secure at regular spans

- avoid sharp bends

) can restore integrity. Recognising the importance of proper handling during installation can significantly extend the lifespan of your electrical cable 3 core 4mm, safeguarding your system against future complications.

Maintenance and Longevity of 3 Core 4mm Cables

Routine Inspections – Checking for wear, damage, and environmental impacts

When it comes to maintaining the integrity of an electrical cable 3 core 4mm, routine inspections are crucial. Over time, cables are subjected to environmental influences that can subtly erode their durability—think fluctuating temperatures, moisture, and physical wear. Regular checks serve as a safeguard, catching wear and tear before it escalates into hazardous issues.

During inspections, focus on signs of damage such as frayed insulation, exposed conductors, or discolouration. Environmental impacts like corrosion, mould, or surface abrasions can compromise safety and performance. A simple visual examination can reveal much about the cable’s condition, but don’t overlook tactile assessments—feel for softness or brittleness which might indicate underlying deterioration.

To streamline maintenance efforts, consider implementing a systematic approach:

- Inspect the entire length of the cable for wear and damage.

- Check for environmental impacts such as moisture ingress or chemical exposure.

- Ensure protective sheathing remains intact and free from cuts or abrasions.

- Verify that cable connections are secure and free from corrosion.

By prioritising these routine inspections, the longevity of your electrical cable 3 core 4mm can be significantly extended, ensuring both safety and continuous performance in demanding environments. Regular maintenance not only preserves the cable’s integrity but also safeguards the electrical system’s overall health—an investment that pays dividends in reliability and peace of mind!

Repairs and Replacements – When and how to replace damaged sections

Maintenance and longevity are the silent custodians of an electrical cable 3 core 4mm, whispering their importance in every flicker of light and hum of machinery. When damage occurs—be it from environmental stressors or simple wear—the time to act is now. Recognising the signs of deterioration, such as exposed conductors or frayed insulation, can prevent catastrophic failures.

Replacing damaged sections requires a careful, methodical approach. First, ensure the power supply is fully isolated—safety remains paramount! Then, identify the compromised portion of the electrical cable 3 core 4mm and proceed with a precise cut. To restore integrity, use suitable connectors or junction boxes, ensuring each connection is tight and corrosion-free.

- Inspect the entire length of the cable for signs of wear or damage.

- Remove and replace sections that show signs of deterioration.

- Use high-quality connectors to maintain electrical standards and safety.

In the grand theatre of electrical systems, timely repairs and replacements are the act that preserves both performance and peace of mind. When the integrity of an electrical cable 3 core 4mm wanes, swift and skilled intervention ensures the continued harmony of your power infrastructure.

Protective Measures – Using conduits, cable management systems, and other safeguards

In the realm of electrical infrastructure, longevity isn’t a happy accident — it’s a carefully orchestrated dance of protection and maintenance. The electrical cable 3 core 4mm, a vital artery in many installations, demands vigilant safeguarding to prevent deterioration that could threaten safety and performance. Employing robust protective measures such as conduits and cable management systems creates a formidable barrier against environmental stressors—humidity, mechanical impact, and UV exposure—that relentlessly try to diminish cable integrity.

Strategically installed conduits not only shield the cable 3 core 4mm from physical harm but also reduce wear caused by constant movement or vibration. Additionally, cable management systems—clips, trunking, and cable ties—organise wiring, preventing unnecessary strain and ensuring the cable remains flexible and durable over time. For outdoor or exposed environments, weatherproof conduits and specialised sheathing are non-negotiable to withstand the elements and prolong service life.

To further enhance longevity, consider implementing routine inspections that identify early signs of damage or environmental impact. This proactive approach can be bolstered by the use of

- protective sleeves

- cable glands

- junction boxes

all of which serve as additional layers of defence for the electrical cable 3 core 4mm, ensuring safety and compliance while maintaining optimal electrical performance.

Where to Buy High-Quality 3 Core 4mm Cables

Reputable Suppliers and Brands – Leading manufacturers and retailers

In a world where electrical safety and reliability are paramount, sourcing high-quality electrical cable 3 core 4mm becomes a mission of both necessity and integrity. The right supplier doesn’t just provide a product—they offer peace of mind, ensuring every metre of cable upholds rigorous safety standards and durability. Reputable brands often stand out through their commitment to compliance, innovative materials, and customer-centric service. Leading manufacturers such as Prysmian, Nexans, and Southwire have built their reputation on delivering cables that meet international certifications and surpass industry expectations.

For discerning buyers, choosing trusted retailers is equally essential. Established electrical wholesalers and specialised hardware stores often guarantee authenticity, quality assurance, and expert support. When navigating this landscape, it’s wise to prioritise suppliers with a proven track record, robust certification credentials, and positive customer feedback. This attention to detail ensures your investment in electrical cable 3 core 4mm is both sound and sustainable, reflecting a commitment to safety and performance at every connection point.

Factors Influencing Price and Value – Cost considerations, warranties, and after-sales support

When investing in high-quality electrical cable 3 core 4mm, the choice of where to buy can significantly influence both safety and long-term value. Reputable suppliers often carry certifications and adhere to strict safety standards, ensuring you receive a cable that performs reliably under demanding conditions. It’s vital to select sellers who prioritise quality assurance, as a subpar product can compromise safety and incur costs down the line.

Factors influencing the price of electrical cable 3 core 4mm include material quality, brand reputation, and included warranties. While some providers may offer lower prices initially, they might lack comprehensive after-sales support or fail to meet essential safety certifications. Conversely, premium suppliers often include warranties and after-sales service that safeguard your investment, providing peace of mind in case of manufacturing defects or installation issues. When comparing options, consider the overall value—sometimes paying a little more upfront can save you a great deal of trouble later.

For those seeking the best balance of cost and confidence, a trusted supplier with a track record of customer satisfaction can make all the difference. Look for providers that offer detailed product information and transparent pricing. Such transparency allows you to assess whether the electrical cable 3 core 4mm aligns with your specific needs, whether for residential wiring or industrial applications. It’s not just about price; it’s about securing a cable that guarantees safety, durability, and ongoing support throughout its lifespan.

Online vs Offline Purchasing Options – Pros and cons of different purchase channels

Choosing where to buy a high-quality electrical cable 3 core 4mm can make a significant difference in safety and longevity. Online shopping offers convenience and a broad selection, often with detailed product specifications and customer reviews. This transparency helps you compare brands and certifications easily, ensuring you select a cable that meets your requirements. On the other hand, offline purchasing allows for direct inspection of the product. Seeing the cable firsthand can reassure you about its build quality and size, especially for critical applications.

Online channels tend to provide competitive prices and the benefit of swift delivery. However, they may lack immediate expert advice, which can be crucial when choosing a cable for specialised projects. Conversely, physical stores usually have knowledgeable staff who can guide you through safety standards and compatibility issues, but prices might be higher and stock limited. For those prioritising trustworthiness and comprehensive support, a reputable supplier—whether online or offline—remains key.