Understanding Electrical Cable Identification

What is Electrical Cable Identification?

Electrical cable identification is the backbone of safe and efficient wiring systems. Without clear identification, electricians risk costly mistakes or dangerous faults. Properly marked cables ensure that everyone on-site can quickly recognize the purpose and specifications of each wire. In South Africa, where electrical standards are strict, understanding how to interpret cable markings is essential for compliance and safety.

Effective electrical cable identification involves more than just labels. It includes understanding color codes, insulation markings, and the use of standardized symbols. These markers help distinguish between live, neutral, and earth cables, reducing the chance of errors during installation or maintenance. In complex wiring setups, a systematic approach to cable identification saves time and mitigates risks.

For those working with electrical cable identification, familiarity with industry conventions is crucial. Using tools like cable markers, tags, and color-coded sleeves can make a significant difference. Remember, when cables are properly identified, troubleshooting becomes straightforward, and future upgrades or repairs are streamlined, ensuring safety and operational integrity at all times.

Importance of Proper Cable Identification in Electrical Work

In the intricate web of electrical systems, proper cable identification is not just a matter of convenience — it is a cornerstone of safety and operational excellence. With South Africa’s rigorous electrical standards, overlooking the significance of accurate cable marking can lead to costly errors, delays, or even hazardous situations. When each wire is clearly identified, it transforms a complex maze into a navigable network, allowing electricians to work with confidence and precision.

Effective electrical cable identification plays a vital role in minimizing risks during installation, maintenance, and troubleshooting. Recognizing the difference between live, neutral, and earth cables through standardized markings or color codes reduces the potential for accidental contact or faults. A systematic approach, employing tools like cable tags or color-coded sleeves, ensures that every wire’s purpose is unmistakable, streamlining workflows and reinforcing safety protocols. In South Africa’s dynamic electrical landscape, mastering this aspect of electrical cable identification is essential for compliance and peace of mind.

Key Benefits of Accurate Cable Marking

In the realm of electrical craftsmanship, the true power of effective electrical cable identification lies in its ability to turn chaos into clarity. Imagine navigating a dense jungle without a map—each cable a winding vine, each connection a hidden threat. Proper cable marking transforms this wilderness into a navigable landscape, where every wire’s purpose is unmistakable, and safety reigns supreme. It’s an invisible yet vital shield that guards against costly errors and hazardous mishaps.

The true benefit of accurate cable marking extends beyond mere convenience. It provides a strategic advantage during maintenance and troubleshooting, allowing electricians to trace circuits swiftly and confidently. When cables are systematically identified using standardized color codes or tags, it reduces downtime and minimizes risks. This meticulous approach ensures compliance with South Africa’s rigorous electrical standards and elevates operational safety to new heights. In this enchanted world of electrical systems, mastering cable identification is the key to unlocking efficiency and peace of mind.

Types of Electrical Cables and Their Markings

Common Types of Electrical Cables

When it comes to electrical cable identification, understanding the various types of cables and their markings is crucial. Each cable type serves a specific purpose, from transmitting power to data communication, and their markings provide vital clues about their specifications. For instance, the most common types include twin and earth cables, coaxial cables, and armored cables, each designed to meet unique safety and performance standards. Recognizing these distinctions helps prevent costly mistakes and enhances safety on any electrical project.

Markings on electrical cables are more than just labels—they are the language of safety and efficiency. These markings often include information such as voltage ratings, conductor material, and compliance standards. Some markings also specify the cable’s insulation type, which is particularly important in South Africa’s diverse environments. Knowing how to interpret these markings ensures proper electrical cable identification, reducing the risk of failures and hazards. Whether installing new wiring or inspecting existing setups, understanding these signals is essential for any professional in the field.

- Voltage rating

- Conductor material

- Insulation type

- Standard compliance marks

Standard Color Codes for Cable Identification

Imagine walking into a room illuminated by the subtle glow of cables that silently communicate their purpose through a language of marks and colors. Electrical cable identification is more than just reading labels; it’s an art that unlocks the secrets of safety and efficiency embedded within each wire. Different types of electrical cables—like twin and earth, coaxial, or armored—and their markings tell a story about their voltage capacity, conductor material, and insulation type, guiding professionals through complex wiring labyrinths with confidence.

Color coding, in particular, plays a pivotal role in cable identification. Standard color codes for cable identification vary depending on regional standards but often include:

- Brown or red for live wires

- Blue or black for neutral wires

- Green/yellow for earth or grounding conductors

By understanding these nuances, electricians can quickly distinguish between cables, preventing costly errors and ensuring compliance with safety standards. Recognizing these markings is essential in South Africa’s diverse electrical landscape, where proper cable identification safeguards both property and lives.

Numbering and Labeling Systems

Understanding the markings and labeling systems of different electrical cables is essential for safe and efficient wiring. Each type of cable—whether twin and earth, coaxial, or armored—has specific markings that reveal vital information about its construction and capabilities. These markings often include a combination of numbers, letters, and color codes, making electrical cable identification straightforward for professionals familiar with industry standards.

Most cables follow standardized numbering systems to indicate voltage ratings, conductor material, and insulation type. For example, a cable might be labeled with a code like “BV 2.5mm²,” where “BV” denotes the type, and “2.5mm²” specifies the cross-sectional area of the conductor. These labels help electricians quickly determine compatibility and safety compliance during installation or maintenance.

To further simplify identification, many cables incorporate color coding aligned with regional standards. In South Africa, for instance, the color codes for electrical cable identification include brown or red for live wires, blue or black for neutral, and green/yellow for earth conductors. Recognizing these distinctions is crucial in avoiding wiring errors and ensuring adherence to safety regulations.

Methods and Tools for Cable Identification

Visual Markings and Labels

In the realm of electrical cable identification, the tools and methods used can turn a chaotic jumble of wires into a symphony of clarity. Visual markings and labels are the unsung heroes that bring order to this intricate dance of conductors. When properly applied, they not only enhance safety but also streamline maintenance and troubleshooting, saving valuable time and resources.

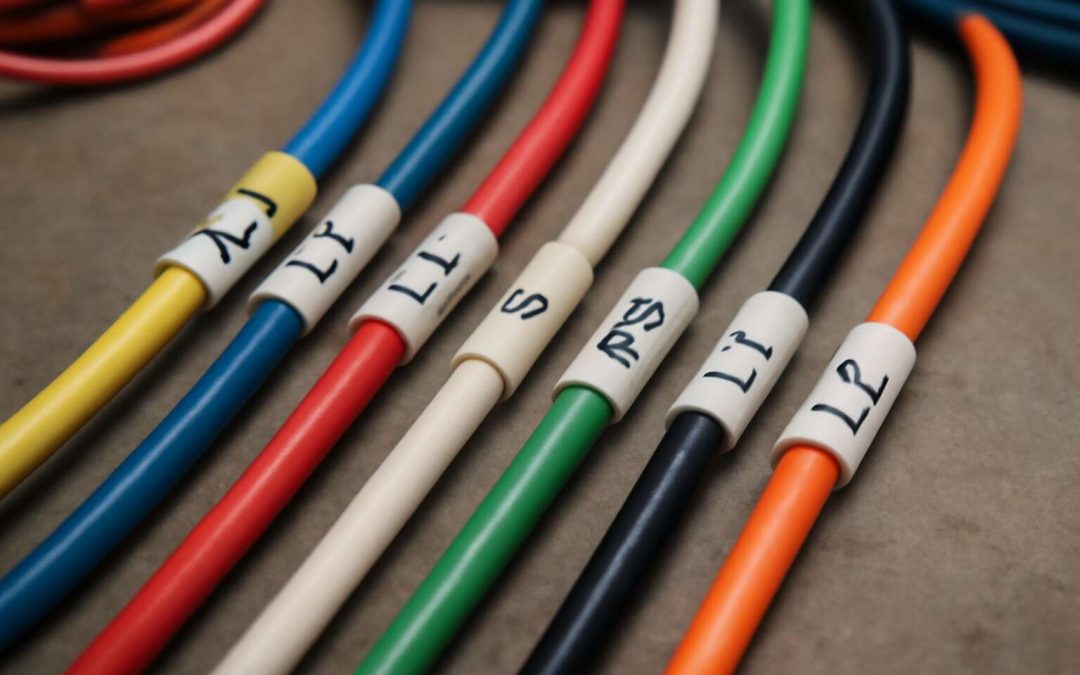

One of the most effective techniques in electrical cable identification involves the strategic use of color-coded tapes, tags, and heat-shrink sleeves. These markers serve as instant visual cues, guiding technicians through complex wiring labyrinths. For added precision, engineers often employ numbered labels or barcodes, creating a robust numbering and labeling system that stands up to South Africa’s demanding electrical environments.

- Durability against harsh conditions

- Ease of application

- Compatibility with existing standards

These tools are essential in ensuring each cable’s purpose and origin are unmistakably clear, paving the way for safer, more efficient work.

Color Coding Systems

In the intricate tapestry of electrical systems, methods and tools for cable identification are the threads that bring clarity and order. Color coding systems stand out as the most intuitive approach, transforming complex wiring layouts into easily decipherable maps. By employing a strategic palette—such as red for power lines, blue for control cables, and green for grounding—technicians can swiftly navigate the labyrinth of conductors. This method not only enhances safety but also accelerates troubleshooting, making maintenance less burdensome.

Beyond colors, the precision of numbered labels and barcodes elevates electrical cable identification to a new level of sophistication. These markers, often resistant to heat, moisture, and chemicals, withstand South Africa’s demanding environments. They serve as silent guides, ensuring that each cable’s purpose and origin are unmistakably clear. For optimal efficiency, many professionals opt for tools like heat-shrink sleeves and durable tapes, which seamlessly integrate into existing standards and workflows.

Identification Tags and Markers

In the labyrinthine corridors of electrical systems, where cables weave an intricate tapestry of purpose and power, precision in electrical cable identification is paramount. Tools and methods designed for this task are the silent guardians of safety and efficiency, transforming chaotic wiring into an organized symphony. Among these, identification tags and markers stand as the pillars of clarity, their resilience forged for the demanding environments of South Africa’s rugged landscapes.

These markers are more than mere labels; they are steadfast sentinels standing guard against confusion and mishaps. Made from heat-resistant, moisture-proof materials, they endure the harshest conditions, ensuring that every cable’s story remains clear and unambiguous. For seamless integration, many professionals turn to innovative tools like heat-shrink sleeves, which snugly embrace cables, or tough tapes that adhere with unwavering strength. When applied with precision, these tools elevate electrical cable identification to an art form, transforming complex wiring into an accessible map for technicians and engineers alike.

Incorporating numbered labels or barcodes into this ecosystem adds a layer of sophistication, allowing for rapid scans and real-time management. An ordered system of labels not only speeds up troubleshooting but also minimizes errors, ensuring every conductor’s purpose is unmistakably clear. This synergy of methods and tools empowers professionals to navigate the cables with confidence, forging a safer, more efficient electrical infrastructure that stands resilient against time and environment.

Advanced Technologies

Harnessing cutting-edge technology in electrical cable identification is transforming the way professionals navigate complex wiring systems. Advanced tools such as RFID tags and barcode scanners enable real-time tracking and management of cables, reducing errors and boosting efficiency. These innovations allow technicians to quickly scan and retrieve vital information about each cable, streamlining maintenance and troubleshooting processes in South Africa’s demanding environments.

Moreover, laser etching and thermal transfer printing have revolutionized the creation of durable, high-precision labels. These methods produce permanent markings that withstand extreme conditions, ensuring long-lasting cable identification even in harsh weather or industrial settings. Integrating these tools into your electrical infrastructure guarantees clarity and safety, making maintenance less of a mystery and more of a straightforward operation.

- RFID tags for wireless identification

- Barcode labels for fast scanning

- Laser etching for permanent markings

- Thermal transfer printers for durable labels

By adopting these innovative methods and tools, professionals in South Africa can elevate their electrical cable identification practices to new heights—turning chaos into clarity with every wire traced and every connection verified.

Best Practices for Effective Cable Identification

Creating Consistent Labeling Systems

In a landscape where safety and efficiency are paramount, mastering the art of electrical cable identification becomes a moral imperative. It’s a silent guardian, a code that whispers clarity amid chaos. When cables are consistently labeled, the risk of costly errors diminishes, and confidence in the workspace surges. Effective cable identification isn’t merely about slapping labels; it’s about creating a visual language that speaks to every technician, engineer, and inspector.

Creating a consistent labeling system involves deliberate planning. Standardized color codes, clear text, and durable tags form the backbone of a reliable system. To streamline this process, consider implementing a layered approach, integrating visual markings with alphanumeric codes. This ensures that even in low-light conditions or hurried inspections, cables tell their story without ambiguity. Remember, a coherent system elevates safety standards and simplifies troubleshooting in complex electrical environments.

Standards and Regulations to Follow

In the intricate dance of electrical safety, adherence to best practices for electrical cable identification becomes an unspoken vow—a moral obligation woven into every wire and connector. Regulations and standards serve as the silent arbiters, guiding technicians to maintain a uniform language that transcends individual interpretation. These standards aren’t rigid rules but frameworks that uphold safety, reduce errors, and foster trust in complex electrical systems.

When establishing cable identification standards, consistency is paramount. Employing a combination of color codes, standardized labels, and clear alphanumeric systems ensures that each cable’s story is unmistakable—even under the most demanding conditions. In South Africa, compliance with national and international standards such as SANS 10142 or IEC guidelines guarantees that electrical cable identification remains clear, reliable, and universally understood. By aligning practices with these regulations, professionals can create a resilient visual language that speaks for itself—reducing downtime, preventing mishaps, and elevating safety to a moral imperative.

Maintaining and Updating Cable Labels

Maintaining and updating cable labels is a vital, yet often overlooked, aspect of effective electrical cable identification. Over time, environmental conditions, wear and tear, or system modifications can compromise the clarity of labels, leading to potential hazards or costly downtime. Regular inspection and refreshment of labels ensure that every cable’s story remains legible and trustworthy, preserving the integrity of the entire electrical system.

To streamline this process, consider implementing a systematic approach. For example, a visual inspection schedule coupled with a standardized protocol for replacing worn or faded labels can prevent misidentification. Additionally, modern solutions like durable, weather-resistant markers and RFID tags can withstand the harsh conditions often found in South African industrial environments.

- Establish a routine audit cycle to identify aging or damaged labels.

- Use high-quality, compliant materials for labels that adhere firmly and resist environmental stressors.

- Maintain a detailed record of updates to ensure traceability and consistency across all systems.

By prioritizing the maintenance and updating of cable labels, professionals can uphold the highest standards of electrical cable identification, fostering safety, efficiency, and confidence in complex electrical networks. This ongoing commitment transforms a simple task into a cornerstone of electrical system excellence—an unbreakable link in the chain of safety and reliability.

Safety Considerations During Identification

In the realm of electrical cable identification, safety isn’t just a guideline—it’s a core principle that can spell the difference between seamless operation and dangerous mishaps. When working with complex electrical systems, especially in South African industrial environments, the stakes are high. Proper identification practices safeguard personnel and prevent costly errors. Ensuring that every cable is correctly labeled and easily distinguishable requires vigilance and adherence to best practices.

One of the most vital safety considerations during electrical cable identification is the use of durable, weather-resistant labels that can withstand harsh conditions. These labels should adhere securely to cables, resisting moisture, dust, and temperature fluctuations—all common in South Africa’s diverse climate zones. Additionally, implementing a systematic approach, such as routine visual inspections, helps catch faded or damaged labels early, preventing misidentification that could lead to equipment failure or safety hazards.

To further enhance safety, consider integrating advanced identification technologies like RFID tags or color-coded markers. These tools allow for quick, reliable recognition even in low-visibility or cluttered environments. A clear, consistent labeling system combined with regular audits ensures that electrical cable identification remains accurate over time, allowing maintenance teams to work confidently and efficiently. When safety and precision are prioritized, the integrity of electrical systems is preserved, fostering a safer working environment for all.

Challenges in Electrical Cable Identification

Issues with Fading or Damaged Labels

When it comes to electrical cable identification, one of the most persistent challenges is dealing with fading or damaged labels. Over time, exposure to harsh South African environmental elements—like intense sunlight, dust, and moisture—can cause markings to become illegible, risking costly miswiring or dangerous faults. Imagine a cable that’s lost its identity, lurking behind walls or beneath equipment, with only faint remnants of its original label hinting at its purpose. This obscurity can turn routine maintenance into a perilous treasure hunt.

In such situations, reliance solely on visual markings is a gamble. The damage often renders color coding systems ineffective, and manual recording becomes unreliable when labels peel or fade. To combat this, many professionals turn to advanced technologies such as barcode labels or RFID tags, which withstand environmental stresses and preserve accurate identification. Ensuring the integrity of electrical cable identification hinges on preemptive measures—like durable labels and consistent updating—so that even in the face of adversity, the true identity of every cable remains clear and secure.

Identifying Cables in Complex Installations

In labyrinthine electrical installations, especially those sprawling across South African industrial sites, the challenge of electrical cable identification can feel akin to deciphering hieroglyphics without a Rosetta Stone. Complex wiring systems often mean a tangle of cables that seem to have conspired to defy logical order. Without proper methods of identification, technicians risk unwittingly tampering with live circuits or creating hazardous faults—an outcome no professional desires.

The intricacies of cable routing, coupled with limited access points, make visual markings insufficient. Over time, labels fade into obscurity or are obscured behind walls, leaving only a faint ghost of their original purpose. This ambiguity demands a nuanced approach, often involving layered identification strategies. For example, a cable might be identified through a combination of color coding and numbered tags, but even these can become unreliable if not maintained diligently. Some industries have turned to RFID tags or barcode labels, which withstand environmental elements like dust, moisture, and intense sunlight—common adversaries of reliable electrical cable identification.

In these challenging environments, a simple list can make all the difference:

- Implementing durable, weather-resistant labels

- Regularly updating identification records

- Utilizing advanced tech like RFID tags for long-term reliability

Without such measures, the task of electrical cable identification transforms from a routine check into a perilous treasure hunt, risking safety and efficiency. It’s a stark reminder that, in the realm of electrical work, the devil truly is in the details—and those details are only as reliable as the identification systems that support them.

Dealing with Different Standards Globally

Across borders and industries, the challenge of electrical cable identification is magnified by the inconsistency of standards. In South Africa, as in many parts of the world, differing national and international codes can create a labyrinth of confusion for technicians. Navigating these divergent standards isn’t simply a matter of compliance but a test of vigilance and adaptability. Each country’s approach—be it color coding, labeling, or tagging—may conflict with another, complicating cross-border projects or multinational operations.

In some cases, this disparity forces professionals to develop hybrid systems, blending elements from various standards to create a cohesive identification scheme. The stakes are high: misinterpretation can lead to dangerous faults or delays that ripple through entire operations. The complexity underscores the importance of establishing a comprehensive, standardized approach to electrical cable identification that considers local regulations, industry best practices, and technological advancements.

Choosing the Right Cable Identification Solutions

Factors to Consider

Choosing the right electrical cable identification solutions is akin to selecting the perfect accessory for an ensemble—every detail counts. In South Africa’s bustling construction sites and intricate wiring systems, clarity in cable marking can mean the difference between safety and chaos. A well-implemented system reduces errors, speeds up maintenance, and ensures compliance with local standards. But how do you determine which method suits your unique project? The answer lies in carefully weighing several factors that influence the effectiveness of electrical cable identification.

First and foremost, consider the environment in which the cables will reside. Harsh conditions—be it moisture, heat, or exposure to chemicals—demand durable labels capable of withstanding wear and tear. Additionally, the complexity of your installation plays a crucial role; intricate systems with numerous cables benefit from a combination of color coding systems and advanced technologies like RFID tags. To streamline the process, some professionals favor a

- comprehensive labeling system

- visual markings

- robust identification tags

that integrate seamlessly, ensuring consistency and easy recognition across the board.

Ultimately, aligning your choice with relevant standards and regulations—whether local or international—will safeguard your project from compliance issues. After all, in the realm of electrical cable identification, the devil is in the details—and a thoughtful approach ensures those details speak volumes about professionalism and safety.

Top Manufacturers and Suppliers

When it comes to choosing the right electrical cable identification solutions, partnering with top manufacturers and suppliers can make all the difference. South Africa’s electrical sector is teeming with options, but not all labels are created equal. A good supplier offers high-quality, durable products that can stand up to the country’s challenging environments—think of them as the bodyguards of your wiring system.

Leading brands in the field understand that reliability isn’t just a bonus—it’s a necessity. From robust identification tags to advanced RFID systems, these manufacturers are at the forefront of innovation. For example, some suppliers specialize in flexible, weather-resistant labels perfect for outdoor installations, while others excel in high-precision color coding systems for complex wiring projects.

To streamline your selection process, consider a supplier that offers a comprehensive range of solutions. An ideal provider might offer:

- Customizable labels tailored to your project’s specifications

- Compliance with South African standards and international regulations

- Fast turnaround times for large orders

- Expert technical support and consultation

Choosing the right manufacturer or supplier not only elevates your electrical cable identification but also minimizes errors, enhances safety, and ensures your project ticks all the regulatory boxes. It’s a strategic investment in the longevity and clarity of your wiring infrastructure—because in the world of electrical cable identification, quality truly counts.

Comparing Costs and Features of Identification Tools

Choosing the right electrical cable identification tools can feel like navigating a maze—there are countless options, each claiming to be the best. But when it comes down to comparing costs and features, the real trick is finding a balance between budget-friendly solutions and durable, dependable products. After all, a cheap label that fades after a shower of rain isn’t doing anyone any favors.

For a savvy electrician in South Africa, it’s essential to assess what features matter most. Do you need weather-resistant labels that can withstand our unpredictable climate? Or perhaps high-precision RFID systems that make complex wiring a breeze? Here’s a quick rundown:

- Cost-effectiveness: Can the tool deliver value without breaking the bank?

- Durability: Will it endure outdoor conditions or harsh environments?

- Ease of use: Is the identification method user-friendly for quick deployment?

- Compliance: Does it meet South African standards and international regulations?

In the end, the best electrical cable identification solution isn’t just about the lowest price; it’s about matching features to your project’s unique needs. After all, investing in quality labels and markers ensures your wiring stays clear, safe, and compliant—saving you time and money in the long run.