Understanding Electrical Cable Routing Layout

Definition and Importance

Understanding electrical cable routing layout is fundamental to constructing a safe and efficient electrical system. It’s more than just plotting wires; it’s about orchestrating a symphony of connections that ensures reliability and longevity. An effective layout minimizes the risk of electrical faults, reduces maintenance costs, and enhances overall safety for both installers and end-users. In South Africa, where diverse building standards and environmental factors come into play, meticulous planning of the electrical cable routing layout becomes even more vital.

By carefully considering the pathways for cables, engineers and electricians can avoid hazards such as overheating or accidental damage. The layout must also accommodate future expansion, a common necessity in growing urban landscapes. Often, professionals use a combination of physical barriers and strategic placement to ensure cables are protected and easily accessible. In fact, a well-designed electrical cable routing layout acts as the backbone of any successful electrical installation, ensuring seamless operation and peace of mind for years to come.

Key Components of Cable Routing

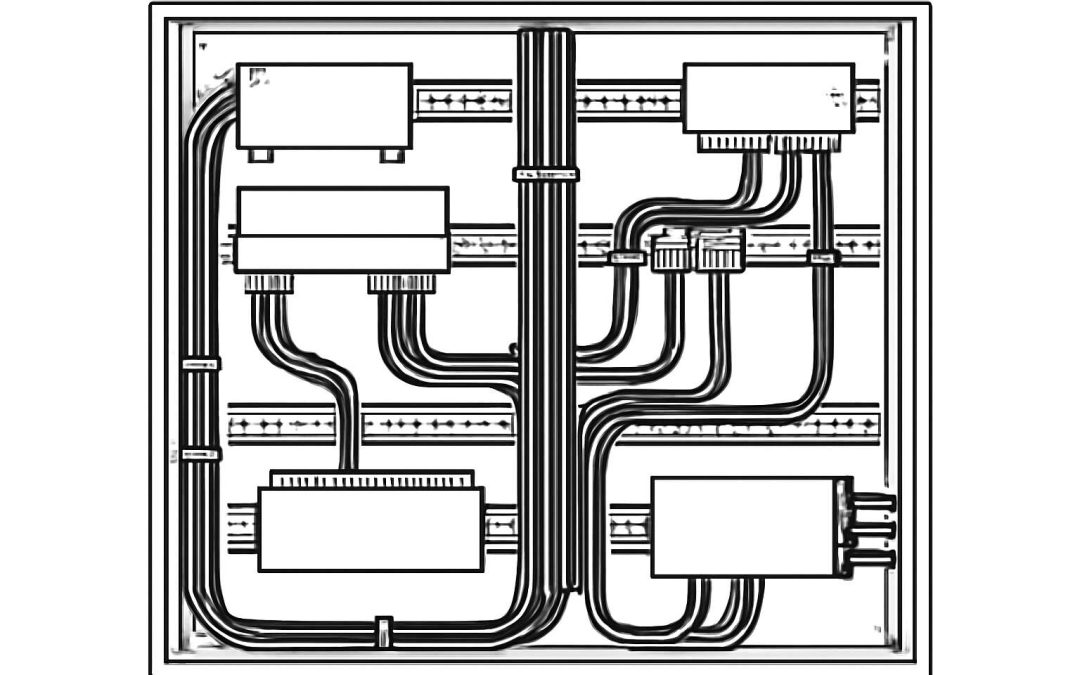

Understanding the electrical cable routing layout is crucial for creating a safe and reliable electrical system. The key components of cable routing involve more than just placing wires haphazardly; it requires a strategic approach that considers safety, accessibility, and future expansion. Properly planned pathways help prevent overheating, accidental damage, and difficult maintenance issues down the line.

In designing an effective electrical cable routing layout, several elements come into play, including physical barriers, protective conduits, and strategic placement. These components serve to shield cables from environmental hazards and mechanical stress, ensuring longevity and consistent performance. Sometimes, this involves careful routing around existing structures or incorporating dedicated cable trays and conduits to streamline the process.

To facilitate clarity and efficiency, many professionals use a combination of

- physical barriers

- cable trays

- conduits

when planning the layout. These components work together to form a comprehensive network that supports both current needs and future upgrades, making the electrical cable routing layout adaptable and resilient in South Africa’s diverse building environments. This meticulous attention to detail ultimately underpins the safety and durability of the entire electrical installation process.

Common Applications and Settings

Electrical cable routing layout is a critical element in many South African installations, spanning diverse environments from commercial buildings to industrial sites. Proper routing ensures safety, minimizes interference, and facilitates easier maintenance. In factories, a well-planned layout can prevent overheating and accidental damage, which are common risks in hectic industrial settings.

Common applications of electrical cable routing layout include office complexes, where flexible pathways accommodate future expansion, and residential developments requiring neat, accessible wiring. Strategic placement of conduits and cable trays is essential to avoid obstructions and environmental hazards. These components work together to create a resilient network that adapts to the unique demands of South Africa’s diverse building environments.

In many cases, a combination of physical barriers, protective conduits, and cable trays forms the backbone of an effective electrical cable routing layout. This approach not only enhances safety but also simplifies troubleshooting and upgrades. Whether in a high-rise or a remote facility, a thoughtful cable routing layout is the foundation of a reliable electrical system—one that stands the test of time and use.

Design Principles for Effective Cable Routing

Safety Considerations

In the intricate dance of designing an electrical cable routing layout, safety isn’t just a guideline—it’s the very heartbeat of the process. An effective layout weaves protection into every twist and turn, ensuring that cables are shielded from potential hazards while maintaining ease of access for maintenance. When planning, consider the environment’s unique demands, such as moisture, heat, or mechanical stress, which can turn a simple routing task into a perilous challenge if overlooked.

Fundamental to this process is the adherence to core design principles that prioritize safety without sacrificing efficiency. For example, maintaining appropriate separation distances between power and data cables minimizes electromagnetic interference, safeguarding signal integrity. Furthermore, incorporating clear pathways and accessible junction points in your electrical cable routing layout fosters swift repairs and reduces risk during emergencies.

- Minimize cable length to reduce electrical resistance and potential overheating.

- Use protective conduits and cable trays to shield cables from physical damage.

- Mark and label cables meticulously to prevent accidental disconnections or misidentification.

Accessibility and Maintenance

Effective electrical cable routing layout isn’t just about fitting cables neatly; it’s about ensuring long-term accessibility and ease of maintenance. When designing, prioritize clear pathways that allow technicians to reach junction points without hassle. This reduces downtime and minimizes safety risks during repairs.

Incorporating thoughtful design principles means considering the environment and potential obstacles. Use dedicated cable trays and conduits to keep cables organized and protected from mechanical stress. Proper labeling and color coding further streamline troubleshooting, preventing misidentification and accidental disconnections.

Remember, a well-planned electrical cable routing layout balances safety with efficiency. For instance, maintaining appropriate separation distances between power and data cables helps reduce electromagnetic interference, safeguarding signal integrity. Ultimately, a meticulous approach simplifies maintenance and enhances system reliability!

Minimizing Interference and Signal Loss

In the silent ballet of electrical cable routing layout, where every wire whispers its path onto the stage, the harmony of design becomes paramount. Minimizing interference and signal loss is not merely a technical chore but an art—one that safeguards the symphony of data and power coursing through our modern world. When cables intertwine without purpose, chaos ensues; but with deliberate arrangement, clarity reigns.

One fundamental principle is spatial separation. Think of power and data cables as dancers moving in distinct routines—keeping them apart reduces electromagnetic interference, preserving signal fidelity and ensuring system integrity. To achieve this, consider employing dedicated cable trays and conduits, which serve as the arteries of organized flow, protecting cables from mechanical stress and environmental hazards.

Furthermore, adopting thoughtful routing strategies such as:

- Implementing proper shielding where necessary

- Routing high-voltage cables separately from low-voltage data lines

- Using color coding and clear labels to distinguish different circuits

can dramatically enhance the effectiveness of the electrical cable routing layout. These design principles forge a path that balances safety, efficiency, and longevity—transforming a tangled mess into a masterpiece of engineering precision, ensuring the system’s resilience against the rigors of time and environment.

Compliance with Electrical Codes

In the intricate world of electrical cable routing layout, compliance with electrical codes is the secret sauce that keeps chaos at bay and safety firmly in place. Think of it as the rulebook for the modern wiring symphony—ignoring it risks not just fines but the very fabric of safety itself. To master this art, understanding and adhering to local electrical standards is non-negotiable, especially in South Africa where regulations can be as diverse as the landscape.

Effective cable routing design relies on a few fundamental principles that ensure both safety and efficiency. First, always respect the separation distances outlined for different cable types—power cables deserve their own space, away from sensitive data lines, to prevent electromagnetic interference. Additionally, proper routing strategies include using dedicated cable trays, conduits, and adhering to the specific clearance requirements stipulated in electrical codes.

Incorporating these elements into your electrical cable routing layout isn’t just about ticking boxes—it’s about forging a resilient, future-proof system. After all, a well-planned layout not only complies with electrical codes but also saves time and money when it comes to maintenance and upgrades. Remember, in the realm of electrical wiring, the devil is in the details, and ignoring these principles can turn a tidy installation into a tangled, hazardous mess.

Planning Your Cable Routing Layout

Assessing Electrical Load Requirements

In the labyrinthine world of electrical systems, one fact remains startling: a well-designed electrical cable routing layout can save a project from chaos or catastrophe. It’s the silent hero ensuring that electricity flows seamlessly, without the drama of tangled messes or unforeseen hazards. Before diving into the trenches of installation, assessing the electrical load requirements is paramount. Neglect this step, and you risk underestimating the power needs, leading to overheating or equipment failure—hardly the kind of surprise any project needs.

To craft an efficient electrical cable routing layout, it’s wise to categorize circuits based on their purpose and expected load. For example, heavy machinery demands robust cables, while lighting circuits can be more modest. An effective approach involves creating a detailed load assessment, which guides the placement of cables to optimize safety and functionality. This step often involves a simple yet crucial list:

- Identifying all power sources

- Calculating peak load demands

- Considering future expansion needs

By balancing these elements, the electrical cable routing layout becomes a blueprint for reliability, ensuring that every connection is deliberate and capable of handling South Africa’s unique electrical demands with grace and resilience.

Mapping the Building or Area Layout

Mapping the building or area layout is a crucial step in designing an effective electrical cable routing layout. It’s more than just drawing lines on a blueprint; it’s about understanding how spaces are used and how electricity needs to flow through them seamlessly. When you have a clear representation of the physical space, it becomes easier to plan the most efficient pathway for cables, avoiding obstacles and minimizing potential hazards.

Imagine walking through a site where every cable has a purpose, neatly tucked away without crossing or tangling—this is the beauty of meticulous planning. To achieve this, consider creating a detailed diagram that highlights key elements such as walls, doors, and existing infrastructure. This visual map acts as a guiding star, ensuring your electrical cable routing layout is both practical and resilient.

In some cases, employing an ordered numbered list can help organize the process:

- Survey the building’s dimensions and structural features.

- Identify key locations for power sources, outlets, and equipment.

- Map out potential cable pathways that adhere to safety and accessibility standards.

By integrating these steps into your planning process, the electrical cable routing layout transforms from a mere schematic into a reliable blueprint—one that anticipates future needs and adapts to the unique demands of South African buildings. This thoughtful approach ensures a resilient and efficient electrical system, vital for both safety and long-term functionality.

Identifying Power Sources and Endpoints

At the heart of a well-designed electrical cable routing layout lies the precise identification of power sources and endpoints. This process is not merely about marking outlets and switches; it’s about understanding the pulse of the building’s energy flow. When you pinpoint where electricity originates—be it a main panel or substation—and where it needs to reach, you breathe life into a plan that ensures resilience and safety. Every endpoint, every outlet, every piece of equipment must harmonize with the overarching electrical infrastructure.

To streamline this process, consider creating an ordered approach:

- Identify primary power sources and distribution panels.

- Map out critical endpoints like outlets, switches, and equipment connections.

- Determine optimal pathways that connect these points efficiently while adhering to safety standards.

This meticulous attention to detail transforms an electrical cable routing layout from a simple schematic into a strategic blueprint—one that anticipates future needs and minimizes potential hazards. In South Africa’s unique building landscape, such foresight is essential for crafting systems that are both resilient and adaptable to evolving demands.

Creating a Wiring Diagram

In the shadowed corridors of electrical design, crafting an impeccable electrical cable routing layout is akin to weaving a dark tapestry of connectivity. Every strand must flow with purpose, linking the vital power sources to the unseen arteries of a building’s heartbeat. Creating a wiring diagram serves as the master’s blueprint—charting the clandestine pathways where cables whisper through walls and ceilings, unseen yet essential.

To forge a resilient and harmonious layout, consider meticulously plotting the primary power sources—be they the main panel or substation—and aligning them with critical endpoints like outlets, switches, and equipment. This careful mapping transforms a mere schematic into a strategic blueprint, foreseeing future demands and safeguarding against hazards. In South Africa’s unique construction landscape, where environmental and infrastructural nuances challenge even the most seasoned electricians, such precision becomes an art form.

Types of Cable Routing Methods

Surface-mounted Cable Management

Surface-mounted cable management remains one of the most accessible and visually appealing methods within an electrical cable routing layout. It offers a seamless way to keep cables organized, ensuring both safety and aesthetic appeal. This technique is especially popular in environments where ease of access for maintenance and modifications is paramount. When executed thoughtfully, surface-mounted configurations can transform a cluttered space into a sleek, efficient workspace that champions both form and function.

For those seeking a streamlined approach, installing cable trays or conduits along walls provides a disciplined pathway for wires, reducing the risk of damage or interference. The beauty of this method lies in its simplicity and adaptability. It allows technicians to quickly identify and troubleshoot issues without dismantling entire sections of the system. In essence, surface-mounted cable management elevates the overall effectiveness of an electrical cable routing layout, ensuring reliable power delivery while maintaining a clean, professional appearance.

Concealed Cable Raceways

Concealed cable raceways represent a sophisticated approach to electrical cable routing layout, seamlessly integrating wiring behind walls, ceilings, or floors. This method offers a sleek, uncluttered appearance that enhances the aesthetic appeal of any space—be it a modern office or a residential home. Unlike surface-mounted options, concealed raceways keep cables hidden from view, reducing visual noise and creating a cleaner environment.

Implementing concealed cable raceways requires careful planning, particularly in mapping the building or area layout to determine optimal pathways. This ensures cables are not only hidden but also accessible for future upgrades or maintenance. The beauty of this method lies in its ability to protect cables from physical damage while maintaining compliance with electrical codes. For spaces where aesthetics and safety are paramount, concealed raceways prove to be an invaluable element of the electrical cable routing layout.

When considering concealed cable raceways, it’s helpful to evaluate the different types available. These include:

- Surface-mounted raceways that are painted or finished to blend with walls

- In-wall systems designed for easy installation and access

- Drop ceilings with integrated raceways for flexible wiring pathways

Each type offers unique advantages, but all serve to elevate the overall functionality and visual harmony of an electrical cable routing layout. This approach not only ensures reliable power delivery but also preserves the integrity of interior design—an essential aspect in today’s professional and residential spaces across South Africa.

Underground Conduits

Underground conduits are the secret agents of an impeccable electrical cable routing layout—hidden, reliable, and surprisingly versatile. These conduits snake beneath floors, gardens, or driveways, protecting cables from the daily onslaught of foot traffic, gardening tools, and the odd curious pet. Designed to withstand South Africa’s unpredictable climate, they ensure power stays connected without turning your yard into a spaghetti junction of wires.

When selecting the right underground conduit system, consider:

- Material durability—PVC or flexible metal conduits are popular choices for their resilience.

- Size and capacity—ensuring they accommodate future upgrades or additional wiring.

- Installation complexity—some systems demand more digging and trenching than a medieval excavation.

Opting for a well-planned underground conduit network can dramatically streamline your electrical cable routing layout, minimizing future maintenance headaches and safeguarding your setup from the South African elements. It’s a discreet hero behind the scenes—keeping your power flowing smoothly while maintaining a clean, uncluttered environment. Truly, underground conduits are the unsung champions of modern electrical infrastructure!

Wireless Wiring Alternatives

In many South African settings, the traditional method of running electrical cables through walls or ceilings may not always be practical or safe. That’s where wireless wiring alternatives come into play—an innovative approach that’s gaining traction among homeowners and builders alike. These methods eliminate the need for extensive trenching or drilling, offering a cleaner, more flexible solution for complex electrical cable routing layout challenges.

Wireless options such as powerline communication systems or remote power distribution units can significantly reduce installation time and cost. For outdoor spaces or areas where underground conduits aren’t feasible, these alternatives provide a seamless connection without compromising safety or functionality. They are particularly beneficial in rural environments, where maintaining the natural beauty of the landscape is paramount.

However, selecting the right method depends heavily on your specific electrical load requirements and the environment’s susceptibility to interference. Sometimes, a hybrid approach combining concealed cable raceways with wireless solutions can deliver optimal results for your electrical cable routing layout, ensuring reliability and efficiency while preserving aesthetic appeal.

Tools and Materials for Cable Routing

Common Tools Needed

Crafting an impeccable electrical cable routing layout demands more than just intuition; it requires a symphony of precision tools and reliable materials. When delving into this intricate task, having the right equipment can mean the difference between a seamless installation and a costly oversight. Essential tools such as wire strippers, conduit benders, and voltage testers serve as the backbone of any professional’s toolkit, ensuring every cable is routed with finesse and safety. The choice of materials, from high-quality cables to durable conduit systems, also plays a pivotal role in creating a resilient and efficient layout.

For optimal results, consider assembling a comprehensive kit that includes:

- Wire strippers and crimpers

- Conduit benders and fish tapes

- Voltage testers and multimeters

- Cable ties and mounting brackets

With these tools and materials at your disposal, designing an electrical cable routing layout becomes an art—balancing functionality with durability, all while adhering to safety standards. It’s this meticulous preparation that transforms a complex wiring project into a masterpiece of engineering and craftsmanship, perfectly suited to the unique demands of South African environments.

Cable Types and Specifications

Choosing the right tools and materials is the backbone of an efficient electrical cable routing layout. In South Africa, where building environments vary from urban apartments to rural homesteads, selecting durable and reliable components becomes even more critical. Quality wire strippers, conduit benders, and voltage testers ensure that every cable is installed with precision and safety, reducing the risk of future issues. It’s these carefully chosen materials that help craft a resilient wiring system capable of withstanding the diverse South African climate.

For a seamless installation, professionals often rely on a combination of tools such as cable ties, mounting brackets, and fish tapes. These elements streamline the process, making it easier to maneuver cables through confined spaces or complex layouts. When considering cable types and specifications, it’s essential to select cables suited for specific environments—be it high-temperature areas, moisture-prone zones, or areas demanding robust insulation. The right choice of cables not only ensures safety but also longevity in your electrical cable routing layout.

Supporting Hardware and Accessories

When it comes to establishing a robust electrical cable routing layout, the right tools and materials are paramount. These elements form the backbone of a safe, efficient installation that can withstand South Africa’s diverse climate zones. Quality supporting hardware like cable ties, mounting brackets, and fish tapes are essential for securing and maneuvering cables through tight spaces and complex pathways. These accessories not only streamline the process but also ensure that cables stay in place over time, reducing the risk of wear and accidental disconnections.

In addition, selecting the appropriate supporting hardware tailored to specific environments enhances durability. For instance, UV-resistant cable ties and corrosion-proof brackets are vital for outdoor or humid settings. To facilitate a seamless installation, many professionals rely on a combination of these accessories—assembled thoughtfully to match the unique demands of each project. Whether you’re working on an urban apartment or a rural homestead, these materials are instrumental in creating a resilient electrical cable routing layout that stands the test of time.

Best Practices for Installing Cable Routing Layouts

Preparing the Installation Site

Establishing a precise and efficient electrical cable routing layout is fundamental to a safe and dependable electrical system. When preparing the installation site, attention to detail can prevent future headaches such as signal interference or costly repairs. A well-designed layout not only streamlines the installation process but also enhances the longevity of the cables and connected equipment.

Before laying out the cables, it’s crucial to clear the area of obstructions and evaluate existing infrastructure. This step ensures that cables are routed along paths that minimize exposure to potential damage, such as foot traffic or environmental hazards. Incorporating cable management solutions like conduits or raceways can further protect the wiring and maintain a tidy appearance.

In some cases, utilizing a combination of surface-mounted cable management and concealed raceways provides flexibility and aesthetic appeal. For complex installations, creating a detailed wiring diagram can serve as a blueprint, guiding the placement and connection points for the cables. Remember, the ultimate goal is to craft an electrical cable routing layout that balances safety, accessibility, and efficiency, all while adhering to local electrical codes and standards.

Proper Cable Securing and Support

Ensuring proper cable securing and support is the unsung hero of a robust electrical cable routing layout. A meticulous approach here prevents sagging, stress, and eventual damage—issues that could turn a simple installation into a costly affair. Using quality supporting hardware such as cable clamps, conduit straps, and cable ties—preferably those rated for the specific cable type—can make all the difference. Proper spacing and anchoring not only prolong the lifespan of your cables but also maintain the integrity of the entire electrical system.

For intricate setups, consider implementing a structured support system that aligns with the overall electrical cable routing layout. This includes adhering to manufacturer specifications for support intervals and securing cables at regular intervals to prevent unnecessary movement. Remember, a well-supported cable is a happy cable, and happy cables lead to a safer, more reliable installation. For added clarity, some professionals prefer to follow a numbered sequence when supporting cables:

- Secure cables at the start and end points.

- Maintain consistent support intervals.

- Use appropriate hardware to avoid crushing or damaging the cables.

In South Africa, where environmental factors such as humidity and temperature fluctuations are a concern, choosing corrosion-resistant hardware for your electrical cable routing layout is not merely prudent—it’s essential. A thoughtful combination of secure fastening and strategic support ensures your wiring remains resilient, accessible, and compliant with local standards, thereby transforming a mundane task into an art form of electrical craftsmanship.

Avoiding Common Pitfalls

In the intricate dance of wiring, the finesse of a well-executed electrical cable routing layout can mean the difference between a harmonious system and a chaotic tangle of cables. When installing, attention to detail is paramount—each step echoing the precision of an artisan crafting a masterpiece. Overlooking common pitfalls can lead to prolonged maintenance, signal interference, or even hazardous conditions that threaten safety and reliability.

One of the most vital practices is maintaining a disciplined approach to cable support. In environments where environmental factors such as humidity and temperature fluctuations are prevalent—especially in South Africa—using corrosion-resistant hardware ensures longevity. For optimal results, some professionals adopt a sequential method: securing cables at the start and end points, followed by maintaining consistent support intervals along the entire length. This disciplined approach prevents unnecessary movement and reduces stress on the cables, preserving their integrity over time.

To further enhance the robustness of your electrical cable routing layout, consider implementing a structured support strategy. Use cable clamps, conduit straps, and cable ties rated for specific cable types, ensuring each piece of hardware aligns with the unique demands of your installation. Incorporating a numbered sequence—such as supporting at every support interval—can foster clarity and consistency, especially in complex setups where multiple cables converge.

In addition, always tailor your methods to local standards and environmental conditions. For example, underground conduits in South Africa require extra vigilance against moisture and corrosion. Choosing appropriate, durable materials not only complies with regulations but also transforms mundane installations into a testament of craftsmanship. Remember, a meticulously planned electrical cable routing layout isn’t just about neatness; it’s about fostering a resilient, accessible, and safe electrical infrastructure that stands the test of time.

Testing and Certification

Testing and certification are critical stages in ensuring your electrical cable routing layout meets safety standards and performs reliably over time. Without proper verification, hidden faults or substandard installations could compromise safety and lead to costly repairs down the line. It’s essential to conduct thorough inspections, including insulation resistance testing and continuity checks, to confirm that every cable is correctly installed and functioning as intended.

In South Africa, local regulations often mandate specific certifications for electrical work. These procedures help identify potential issues early, ensuring compliance and avoiding future legal complications. A well-executed testing process provides peace of mind, knowing that your electrical cable routing layout adheres to industry standards and environmental conditions.

For complex cable installations, adopting a systematic approach is advisable. An ordered sequence—such as testing from the main power source outward—can streamline diagnostics and pinpoint vulnerabilities quickly. Remember, a resilient electrical infrastructure depends on meticulous verification, especially when supporting critical systems that require unwavering reliability and safety.

Troubleshooting and Maintenance of Cable Routes

Identifying Issues

In the world of electrical cable routing layout, troubleshooting and maintenance are crucial for ensuring safety and system longevity. Faulty cable connections or damaged insulation can cause serious electrical issues, risking both property and personnel. Recognizing early signs of trouble, such as flickering lights or unusual heat around conduit areas, can prevent costly repairs down the line.

One effective method to identify issues involves systematic inspection, focusing on potential problem zones like junctions, support points, and bends. Visual checks combined with testing tools—such as cable testers and insulation resistance meters—help pinpoint faults quickly. Remember, a well-executed cable routing layout simplifies troubleshooting, making it easier to locate and resolve issues with minimal disruption. When maintenance is needed, always follow safety protocols to avoid accidents, especially in complex or concealed cable systems.

Preventative Maintenance Tips

Electrical cable routing layout isn’t just about neatly running wires from point A to B; it’s the backbone of system durability and safety. When troubleshooting issues, a methodical approach can save you from a tangled mess of problems. Start with visual inspections—look for signs like discoloration, melting insulation, or loose connections. Those tiny clues often whisper secrets about hidden faults lurking in your cable routes.

Next, employ testing tools such as cable testers and insulation resistance meters to diagnose faults without tearing down walls or ripping up floors. Remember, a well-planned cable routing layout makes these checks faster and more effective. For preventative maintenance, regularly inspect support hardware—support clamps, conduit bends, and junction boxes—to prevent sagging or stress points that could compromise cable integrity. An ounce of prevention, after all, keeps the costly repairs at bay and ensures the longevity of your electrical system.

In the world of electrical cable routing layout, proactive maintenance isn’t just smart; it’s essential. Keep your cables happy, your system robust, and your troubleshooting sessions breezy! And always adhere to safety protocols—because shocking surprises are best avoided, especially when working with concealed or underground wiring.

Upgrading and Modifying Layouts

Maintaining an efficient electrical cable routing layout is crucial when it comes to troubleshooting and ongoing maintenance. Over time, even the most meticulously planned cable routes can develop issues—loose connections, insulation degradation, or unexpected interference. Regular inspections are a cornerstone of effective troubleshooting, revealing subtle clues like discoloration or frayed insulation that hint at underlying faults.

Upgrading or modifying your cable routing layout isn’t just about aesthetics or compliance; it’s about future-proofing your electrical system. When considering layout modifications, prioritize accessibility and support hardware integrity. For example, using organized conduit systems or raceways can significantly simplify inspection and repair processes. To streamline these efforts, a step-by-step approach can be helpful:

- Assess current cable routes and identify areas needing upgrade or rerouting.

- Plan new pathways that minimize interference and facilitate easier access.

- Implement upgrades with attention to supporting hardware and cable securing methods.

Sometimes, a simple reroute can resolve persistent issues, reduce signal loss, and improve system robustness. Whether installing underground conduits or surface-mounted raceways, each modification should consider the overall electrical load and future expansion possibilities. Thoughtful adjustments—done with precision—can extend the lifespan of your cable infrastructure, making maintenance far less cumbersome and more cost-effective.

When undertaking such upgrades, it’s essential to document every change meticulously. Mapping the modified electrical cable routing layout ensures that troubleshooting remains straightforward and that safety standards are upheld—especially when working in complex environments or underground systems. Properly planning and executing modifications preserves system integrity, prevents unforeseen failures, and keeps your electrical infrastructure resilient in the long run.

Choosing the Right Professional for Cable Layout Design

Qualifications and Certifications

Choosing the right professional to orchestrate your electrical cable routing layout is no mundane task; it is a voyage into the arcane realm of expertise and precision. A master electrician or a certified electrical engineer possesses the qualifications and certifications that serve as the guardian seals of quality and safety. Their credentials—such as a South African National Standards (SANS) certification or a professional registration—are the talismans that ensure the layout adheres to the strictest codes and industry standards.

A seasoned expert understands that the complexity of an electrical cable routing layout demands more than just technical knowledge. It requires an intuitive grasp of building architecture, electrical load demands, and signal integrity. When selecting a professional, look for those with proven experience in similar projects, as well as an eye for detail that can spot potential pitfalls before they emerge from the shadows.

- Relevant qualifications and certifications

- Experience with complex cable routing projects

- Familiarity with local electrical codes and safety standards

In the labyrinth of cables and conduits, only a true craftsman can weave a layout that is both resilient and efficient—transforming a dark, tangled web into a symphony of seamless connectivity.

Selecting Experienced Contractors

Choosing the right professional for your electrical cable routing layout can make all the difference. A skilled contractor not only understands the technical intricacies but also navigates the complexities of building architecture and safety standards seamlessly. In South Africa, verifying qualifications such as a South African National Standards (SANS) certification or professional registration is crucial. These credentials guarantee adherence to local electrical codes and safety standards.

Experience counts. An expert with a proven track record in complex cable routing projects will anticipate potential issues before they arise. When selecting a contractor, consider their familiarity with different cable types, supporting hardware, and installation techniques. A meticulous approach ensures your electrical cable routing layout is resilient, efficient, and safe—transforming a tangled web of cables into a well-organized network that stands the test of time.

Cost Considerations

Choosing the right professional for your electrical cable routing layout can significantly impact your project’s overall cost. Skilled contractors bring efficiency and precision, reducing unnecessary expenses during installation. While it may be tempting to opt for the lowest bid, quality workmanship often pays off in the long run.

Cost considerations should include not only the contractor’s fees but also the complexity of the cable routing layout. More intricate designs involving concealed raceways or underground conduits may require higher investment but offer better aesthetics and safety.

In South Africa, obtaining accurate quotes involves assessing the scope of work, including material costs and potential modifications. An experienced contractor will provide a detailed estimate that accounts for unforeseen complications, helping you avoid budget overruns.

Remember, a well-planned electrical cable routing layout minimizes future maintenance costs and ensures compliance with local electrical standards. Investing in the right expertise now saves money and hassle later!

Emerging Trends in Electrical Cable Routing

Smart Cable Management Solutions

Emerging trends in electrical cable routing layout are revolutionizing how we think about efficiency and safety in modern wiring systems. As the demand for smarter, more adaptable solutions grows, innovative cable management techniques are transforming the landscape. Wireless wiring alternatives, for example, are gaining popularity, reducing clutter and eliminating the need for extensive conduit systems. These advancements not only streamline the installation process but also enhance the aesthetic appeal of both commercial and residential spaces.

One of the most exciting developments is the integration of smart cable management solutions that utilize sensor technology to monitor cable health and detect faults in real time. Such systems can optimize cable pathways, reduce signal interference, and extend the lifespan of electrical infrastructure. Electrical cable routing layout designs now often incorporate modular components that allow for quick upgrades and modifications, keeping pace with rapid technological evolution. Embracing these trends ensures electrical systems remain resilient, efficient, and aligned with contemporary standards in South Africa’s dynamic infrastructural landscape.

Integration with Building Automation

As buildings become smarter and more interconnected, the integration of emerging trends in electrical cable routing layout with building automation systems is revolutionizing how we manage infrastructure. In South Africa’s rapidly evolving infrastructural landscape, this fusion allows for unprecedented levels of control and efficiency. Imagine a system where cables not only carry power but also communicate seamlessly with centralized automation hubs—this is the future of intelligent wiring.

Smart cable routing solutions incorporate sensor technology that continuously monitors cable health, detecting faults before they escalate into costly failures. These sensors can be embedded within the cable pathways, providing real-time data that informs maintenance decisions and minimizes downtime. Such integration ensures that the electrical cable routing layout is not static but adaptive, capable of evolving alongside technological advancements.

- Enhanced safety through fault detection and predictive maintenance

- Streamlined installation with modular components adaptable to building growth

- Optimized signal integrity by reducing interference within complex systems

These innovations exemplify how modern electrical cable routing layout design is shifting from mere conduit management to an intelligent, responsive network—driving resilience and sustainability in South Africa’s building infrastructure. As the demand for smarter buildings increases, embracing these cutting-edge trends becomes not just advantageous but essential. The future belongs to those who understand that wiring systems are no longer just about connectivity—they are about creating a living, breathing infrastructure that adapts, learns, and protects.

Innovations in Cable Materials

As innovation surges forward, the landscape of electrical cable routing layout is witnessing a revolution driven by advancements in cable materials. Traditional copper and aluminum cables are giving way to more resilient, flexible, and environmentally friendly options that cater to South Africa’s dynamic infrastructure needs. New composite materials, infused with fire-retardant and corrosion-resistant properties, elevate safety and longevity, ensuring that wiring systems withstand the harshest conditions.

Emerging trends also highlight the importance of insulation technologies that improve thermal management and reduce energy loss. For example, nanotechnology-enhanced insulations provide superior durability and resistance to electrical interference, making them ideal for complex building automation systems. These innovations not only optimize signal integrity but also contribute to a smarter, more sustainable electrical cable routing layout.

- Flexible, lightweight cables for easier installation in tight spaces

- Self-healing materials that respond to minor faults and prevent escalation

- Eco-friendly cables with biodegradable or recyclable components

Integrating these cutting-edge cable materials into the electrical cable routing layout transforms the infrastructure from simple wiring to an intelligent, adaptive network. This evolution empowers South African buildings to meet modern demands for resilience, safety, and efficiency—unlocking new potentials for sustainable growth across the nation’s cities and rural landscapes alike.