Understanding Electrical Cables Without Earth Wire

Definition and Overview – What are electrical cables without earth wire?

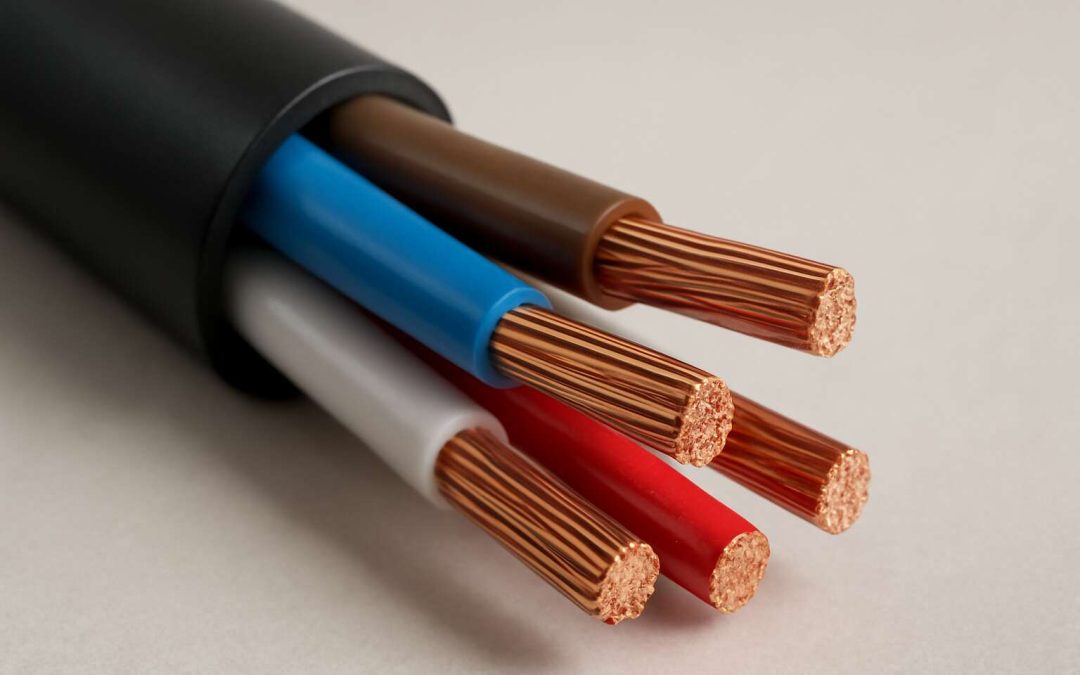

Electrical cable without earth wire might sound like a relic from a bygone era, but it remains prevalent in specific applications. These cables, often called non-earthed cables, lack the crucial safety feature that diverts stray current away from conductive surfaces. While they may seem simpler, they carry a hidden risk that’s not immediately apparent. Understanding the nuances of electrical cable without earth wire is essential—because sometimes, less isn’t more.

Typically used in low-risk environments or for certain appliances, these cables are designed to deliver power without the safety grounding component. However, this absence of an earth wire can dramatically alter the safety profile of an installation. For example, in older buildings where retrofitting might be challenging, electrical cable without earth wire can still be found, but it’s vital to recognise the potential hazards involved. The choice of such cables should always be made with a clear understanding of their limitations and appropriate safety measures.

Types of Cables Without Earth Wire – Common varieties used in electrical installations

Understanding electrical cable without earth wire is crucial for those working in electrical installations. These cables are typically used in low-risk environments or for specific appliances where safety concerns are minimal. They come in various types, each suited to different applications. For example, flat twin and earth cable, often seen in older buildings, is a common variety that lacks an earth wire. Despite their simplicity, these cables pose safety risks if not used correctly. Electrical cable without earth wire is often mistaken for outdated technology, but it still appears in many retrofitted settings, making knowledge of their characteristics essential.

Some of the most common varieties of electrical cable without earth wire include:

- Twin Core and Earth (without the earth conductor)

- Flexible cords designed for portable appliances

- Old-style lighting cables used in vintage fixtures

While these cables may seem straightforward, understanding their limitations helps prevent potential hazards. They are often chosen for simplicity or cost-effectiveness but demand careful consideration of safety standards and proper installation practices. Recognising the differences among these types can make all the difference in ensuring a safe electrical environment.

Industry Standards and Regulations – Safety guidelines and compliance requirements

In the intricate dance of electrical safety, industry standards and regulations serve as the guiding stars, ensuring that every wire and cable performs its role without endangering lives. When dealing with electrical cable without earth wire, compliance becomes even more critical, as these cables often lack the inherent safety features present in modern, earthed counterparts. Regulatory frameworks such as BS 7671 and national wiring regulations set strict guidelines on their use, emphasising the importance of correct installation and suitable applications.

Understanding these safety guidelines is vital. For instance, electrical cable without earth wire must only be employed in low-risk environments where the potential for faults is minimal. The use of such cables in areas with high moisture, exposed wiring, or metal conduit that could conduct current is highly discouraged. To ensure adherence to safety standards, it’s essential to consider factors like voltage ratings, insulation quality, and the compatibility of the cable with the appliance or fixture. Remember, non-compliance can lead to serious hazards, and the consequences are never worth the risk!

For clarity, here are some core compliance considerations:

- Ensure the cable’s specifications match the environment and electrical load.

- Follow manufacturer instructions and local building codes meticulously.

- Regular inspections and testing to detect potential faults early.

By respecting these regulations, professionals can uphold the integrity of their installations, safeguarding both property and lives in the process. The importance of adhering to industry standards when working with electrical cable without earth wire cannot be overstated — safety, after all, is a realm where precision and vigilance reign supreme!

Applications of Electrical Cables Without Earth Wire

Residential Use – When and where these cables are suitable in homes

In the quiet corners of rural homes, where electrical wiring often echoes the simplicity of days gone by, electrical cable without earth wire finds its place. These cables are particularly suitable for low-risk applications, where the electrical system is designed with safety measures that render an earth wire unnecessary. For instance, in lighting circuits or powering small appliances, the absence of an earth wire does not compromise safety when the installation adheres to strict standards.

Many homeowners prefer these cables for their ease of installation and flexibility, especially in environments where traditional grounding methods might be challenging. When working with electrical cable without earth wire, it’s essential to ensure that the circuits are protected by residual current devices (RCDs) or other safety devices. This approach maintains safety without the need for a dedicated earth connection, making these cables ideal for specific residential applications.

- Lighting fixtures

- Low-power sockets

- Internal wiring in appliances designed for earth-free configurations

Understanding where and when to use electrical cable without earth wire can make all the difference in ensuring safe, efficient, and reliable electrical systems within homes. These cables blend practical necessity with safety, reflecting the ingenuity of modern electrical design tailored for diverse living spaces.

Commercial and Industrial Settings – Applications in business and manufacturing environments

In commercial and industrial settings, electrical cable without earth wire often plays a vital role in specific applications. These environments demand reliable wiring solutions that are both safe and efficient. Many manufacturing plants and business premises use these cables where grounding isn’t critical, provided safety measures are meticulously implemented.

For instance, electrical cable without earth wire is commonly employed in control panels, internal wiring of appliances, or low-power lighting circuits. In such cases, safety relies heavily on protective devices like residual current devices (RCDs), which prevent potential hazards without the need for an earth connection. This approach streamlines installation in tight spaces or complex layouts, saving time and reducing costs.

It’s essential to recognise the appropriate applications for electrical cable without earth wire. When used correctly, it maintains safety standards while offering flexibility for various industrial needs. These cables are designed to meet strict industry regulations, ensuring compliance in environments where traditional grounding isn’t feasible or necessary.

Special Situations – Unique cases where earth wire is omitted or unnecessary

In certain niche scenarios, an electrical cable without earth wire isn’t just a quirky choice—it’s a calculated one. Think of specialised equipment or portable devices that operate in environments where grounding might be more of a hindrance than a help. For example, some lightweight appliances or temporary installations may opt for these cables to streamline setup and reduce clutter.

Another fascinating case is in sensor-based systems or low-voltage applications, where safety can be maintained through alternative protective measures. These situations often involve complex, sensitive electronics that are inherently isolated or insulated, making an earth wire redundant. In such cases, the focus shifts from traditional grounding to robust circuit protection, such as digital isolators or advanced RCDs.

- Temporary construction sites, where mobility and speed outweigh permanent safety features.

- Inside sealed enclosures or intrinsically safe environments, where grounding isn’t necessary due to the nature of the components.

- Specific control systems in automation that rely on double insulation or other safety mechanisms rather than earth connections.

While the omission of an earth wire in electrical cable without earth wire might seem risky to the untrained eye, these unique cases prove that with careful planning and adherence to safety standards, it can be a practical solution. It’s a reminder that sometimes, less grounding means more innovation—if you know what you’re doing, of course!

Advantages and Disadvantages of Electrical Cables Without Earth Wire

Advantages – Cost savings, ease of installation, flexibility

In the world of electrical installations, the choice of cable can make or break the efficiency and safety of a system. Electrical cable without earth wire offers notable advantages that often appeal to both professionals and DIY enthusiasts. One of the most compelling benefits is cost savings. Without the need for an earth conductor, the overall material expense drops significantly, making it a more budget-friendly choice. Additionally, these cables tend to be easier to install, especially in tight spaces or complex configurations where flexibility and manoeuvrability are crucial.

Flexibility is another standout feature of electrical cable without earth wire. Their thinner, more streamlined design allows for quicker routing and fewer obstacles during installation. For those concerned with labour costs and time efficiency, this can translate into substantial savings. However, it’s essential to weigh these benefits against potential drawbacks, such as limited safety features in some applications. While these cables are suitable for specific scenarios—like low-risk environments—they are not a universal solution. The choice ultimately hinges on a balance between cost, ease of installation, and adherence to safety standards.

Disadvantages – Potential safety risks, compliance issues, limitations

While electrical cable without earth wire may seem like a practical choice, it is not without its shadows. The absence of an earth conductor can pose significant safety risks, especially in scenarios where grounding is crucial for fault protection. Without proper earthing, electrical faults may go unnoticed, increasing the chances of electric shock or fire hazards. This subtle yet impactful danger underscores the importance of understanding when and where these cables are appropriate.

Furthermore, compliance with industry standards and regulations can become a formidable hurdle. Many safety guidelines mandate the use of earthing in specific applications, making the use of electrical cable without earth wire potentially non-compliant. This risk of legal repercussions and safety violations should not be underestimated.

- Limited safety features in some electrical cable without earth wire configurations.

- Restrictions on their use in high-risk environments or where earthing is mandated by law.

- Potential for increased liability if safety standards are not met.

In essence, while the advantages of cost savings and ease of installation are enticing, the inherent limitations and safety concerns mean these cables are best suited for controlled, low-risk environments. For those committed to safeguarding both property and personnel, understanding these disadvantages is paramount, ensuring decisions are made with both wisdom and caution.

Safety Considerations for Electrical Cables Without Earth Wire

Electrical Safety Risks – Potential hazards associated with ungrounded wiring

In the labyrinth of modern electrical systems, the omission of an earth wire in certain electrical cable without earth wire configurations presents a paradox—an enticing blend of simplicity and peril. While these cables often promise streamlined installation and cost savings, they conceal latent safety risks that can manifest with alarming immediacy. The absence of an earth wire elevates the potential for electrical faults to escalate into hazardous situations, especially when insulation integrity is compromised or when equipment malfunctions occur.

Electrical safety risks associated with ungrounded wiring are not merely theoretical; they can lead to electric shocks or even fires if not meticulously managed. The human element—an inadvertent touch or a faulty device—becomes a conduit for peril. Recognising these dangers underscores the importance of rigorous safety considerations when deploying electrical cable without earth wire, particularly in environments where the stakes are high. Proper insulation, regular inspection, and adherence to industry standards are paramount to mitigate these inherent risks and ensure safe operation, even in the absence of a dedicated earth connection.

Proper Installation Practices – Guidelines to ensure safety and performance

In the silent realm of electrical installation, where precision and safety dance a delicate ballet, the proper installation of electrical cable without earth wire emerges as a critical concern. Despite their allure of simplicity and cost efficiency, these cables demand a meticulous approach to safeguard lives and property. Ensuring optimal performance hinges on understanding and adhering to rigorous safety practices that transcend basic compliance.

One fundamental guideline is to verify that the electrical cable without earth wire is suitable for the specific application. For instance, in environments where metal enclosures are not utilised or where protective earth connections are inherently unnecessary, these cables can serve effectively. However, in settings with high safety stakes, additional measures—such as using residual current devices (RCDs)—become indispensable. These devices act as vigilant sentinels, swiftly disconnecting power in the event of a fault, thereby countering the inherent risks associated with ungrounded wiring.

Furthermore, careful inspection and regular maintenance are paramount. This involves checking insulation integrity, ensuring no wear or damage has compromised the cable’s protective barrier. When installing electrical cable without earth wire, it’s crucial to follow the industry standards meticulously, which often include:

- Proper cable routing to prevent mechanical stress

- Ensuring secure connections to minimise fault potential

- Using appropriate conduit or protective covering to shield against environmental hazards

In essence, the safety considerations surrounding these cables demand vigilance, foresight, and adherence to best practices. While they may offer a streamlined conduit for electric flow, the responsibility of safeguarding those who rely on that flow remains a paramount concern. Every connection, every insulation layer, and every safety device must be orchestrated with the precision of a master conductor—because in the realm of electricity, safety is not just a guideline, but the very rhythm of life itself.

Use of Alternative Safety Measures – Surge protectors, isolation techniques

In the realm of electrical safety, innovation often walks a fine line with tradition. An intriguing statistic reveals that nearly 30% of electrical faults stem from inadequate grounding—highlighting the importance of alternative safety measures when using electrical cable without earth wire. While these cables can streamline installations and reduce costs, they also introduce unique safety considerations that demand careful thought.

One of the most effective safeguards is the utilisation of surge protectors. These devices act as vigilant guardians, absorbing voltage spikes that could otherwise damage equipment or cause hazardous conditions. Additionally, employing isolation techniques—such as installing residual current devices (RCDs)—provides an extra layer of security. RCDs detect imbalance in current flow, promptly disconnecting power to prevent electrocution or fire risks. In environments where electrical cable without earth wire is used, integrating these safety devices is not just recommended; it’s essential.

Moreover, regular inspection and maintenance are vital to ensure ongoing safety. Checking insulation integrity and ensuring secure connections help mitigate potential faults. In some scenarios, a combination of surge protectors and RCDs offers a holistic approach, balancing cost-efficiency with safety. After all, in wiring systems that lack an earth wire, the responsibility to safeguard lives and property becomes even more paramount—demanding vigilance and adherence to the highest standards.

Choosing the Right Cable Without Earth Wire

Factors to Consider – Voltage, load capacity, environment

Choosing the correct electrical cable without earth wire demands a nuanced understanding of several critical factors. Voltage requirements, for instance, serve as the foundation for ensuring safety and compatibility within the system. An inappropriate voltage rating can lead to catastrophic failures, making it essential to meticulously match the cable’s specifications to the intended application.

Load capacity is equally vital; cables must be rated to handle the anticipated current flow without overheating or degradation over time. In environments subject to high temperatures, moisture, or chemical exposure, selecting a cable with suitable insulation and protective sheathing becomes paramount.

While opting for an electrical cable without earth wire might seem advantageous for cost savings or ease of installation, it’s essential to evaluate whether the environment and load conditions justify such a choice. Sometimes, the absence of an earth wire is permissible—particularly in specialised applications—but often, it warrants supplementary safety measures.

Material and Quality – Importance of durable insulation and conductors

When selecting an electrical cable without earth wire, the material and quality of the insulation and conductors are paramount. Durable insulation acts as the first line of defence against electrical mishaps, especially in environments where moisture or chemicals lurk like mischievous gremlins ready to cause chaos. High-quality conductors, typically made from copper or aluminium, ensure efficient current flow and minimise energy loss, making the entire setup more reliable.

In the realm of electrical cable without earth wire, the importance of robust insulation cannot be overstated. It not only safeguards against accidental contact but also prevents deterioration over time, which could lead to exposed conductors and, ultimately, safety hazards. Additionally, selecting cables with insulation rated for specific environmental conditions—be it high temperature, corrosive atmospheres, or damp locations—ensures longevity and safety.

For those pondering whether to opt for a cable without earth wire, it’s often wise to consider the following factors, which can guide material choices and construction standards:

- Insulation material that meets industry standards for durability and safety

- Conductors with high purity copper or aluminium for optimal conductivity

- Protective sheathing resistant to environmental stressors

In essence, investing in high-quality materials for your electrical cable without earth wire isn’t just a matter of compliance but a commitment to safety and performance. After all, a cable’s true worth is measured not just by its price tag but by how well it withstands the rigours of its intended environment—without compromising safety or efficiency.

Compatibility with Electrical Systems – Ensuring integration with existing setups

Choosing the right electrical cable without earth wire is akin to finding a perfectly tailored suit—precision and compatibility are paramount. Ensuring that it seamlessly integrates with your existing electrical system requires a careful assessment of your setup’s unique demands. Compatibility isn’t merely about fitting; it’s about harmonising current capacity, voltage ratings, and insulation standards. A mismatch could turn a benign installation into a safety quagmire or a costly repair.

Before proceeding, it’s wise to verify that your system’s specifications align with the cable’s parameters. For instance, if your wiring involves high currents or operates in challenging environments, selecting a cable with appropriate insulation and conductor ratings is crucial. An ill-suited electrical cable without earth wire might perform adequately initially but could pose safety risks over time, especially if it’s not designed for your particular load or environmental conditions.

In complex or mixed installations, consider using an ordered checklist, such as:

- Voltage compatibility

- Conductor material and capacity

- Environmental resistance (humidity, heat, chemicals)

- Standards compliance

This strategic approach ensures that the electrical cable without earth wire will not only function efficiently but also uphold safety standards, preventing the kind of unforeseen mishaps that turn a simple wiring project into a costly affair. After all, a seamless integration is the hallmark of a truly well-considered electrical installation.

Maintenance and Troubleshooting of Cables Without Earth Wire

Routine Inspections – Visual checks and testing procedures

In a world where safety often takes a backseat to convenience, routine inspections of electrical cables without earth wire are more vital than ever. Despite the absence of a grounding conductor, regular visual checks can reveal telltale signs of wear, such as cracked insulation or discolouration, which could herald trouble ahead. Testing procedures, including insulation resistance tests, are crucial to ensure the cable’s integrity and prevent potential hazards lurking beneath the surface.

An effective maintenance routine might include a simple yet comprehensive checklist. Consider incorporating:

- Visual inspection for signs of physical damage or overheating

- Testing insulation resistance with a multimeter or dedicated tester

- Checking for loose connections or signs of corrosion

Particularly in environments where electrical cable without earth wire is utilised, adherence to safety standards cannot be overstated. Regularly scheduled inspections serve as the first line of defence, catching issues before they escalate into dangerous faults or costly failures—an essential practice to uphold safety and compliance without compromise.

Common Issues – Identifying faults, degradation, or damage

Electrical cable without earth wire may seem straightforward, but faults can develop silently over time. Common issues include insulation degradation, loose connections, or signs of overheating, such as discolouration or melting insulation. Detecting these problems early is essential to prevent potential electrical hazards.

Troubleshooting often begins with a thorough visual inspection. Look for cracks, burns, or exposed conductors. Next, testing the insulation resistance with a multimeter can reveal the integrity of the cable. A low resistance reading indicates deterioration that needs addressing.

In some cases, corrosion may compromise connections, especially in damp environments. Regular maintenance routines—such as tightening terminal screws or replacing damaged sections—are vital. Remember, electrical cable without earth wire relies heavily on proper installation and periodic checks to maintain safety and functionality.

Solutions and Repairs – Best practices for fixing and replacing cables

Maintaining electrical cable without earth wire requires a vigilant approach, combining both preventative measures and prompt troubleshooting. Over time, even the most robust cables can develop faults, which, if left unaddressed, pose significant safety hazards. Regular visual inspections are crucial; look for discolouration, melting insulation, or exposed conductors that might indicate underlying issues. Early detection is key to avoiding costly repairs or dangerous failures.

Testing the insulation resistance with a multimeter is an essential step in troubleshooting. Low resistance readings often reveal deterioration or compromised insulation, signalling the need for repair or replacement. In environments prone to moisture or corrosion, connections can become compromised—regular maintenance routines, such as tightening terminal screws or replacing damaged sections, help maintain safety and optimise performance.

When repairs are necessary, consider the following best practices:

- Switch off power supply before working on any electrical cable without earth wire to prevent shock risks.

- Use appropriate tools and wear protective gear to ensure safety during inspection and repair.

- Replace damaged sections with high-quality, durable insulation materials to sustain longevity and safety.

- Document repairs and inspections meticulously to track the cable’s condition over time.

Implementing these steps not only prolongs the lifespan of the cable but also reinforces a culture of safety and reliability in your electrical system. Whether dealing with minor faults or planning comprehensive replacements, adherence to proper installation practices ensures that electrical cable without earth wire functions optimally—reducing hazards and maintaining compliance with industry standards.

Legal and Regulatory Aspects

Compliance with Local Codes – Legal requirements for cable installation

In the realm of electrical wiring, understanding the legal and regulatory landscape is crucial—especially when dealing with electrical cable without earth wire. Regulations vary widely across jurisdictions, and non-compliance can lead to hefty penalties or safety hazards. Authorities often emphasise strict adherence to local codes, which may specify when and where such cables are permissible.

For example, in some regions, electrical cable without earth wire is permitted in specific scenarios, such as low-voltage lighting circuits or temporary installations. However, these exceptions are tightly regulated, and failure to meet safety standards can compromise entire systems. To navigate this complex terrain, professionals must consult and follow the relevant industry standards and regulations, which might include:

- National electrical safety codes

- Building regulation compliance requirements

- Manufacturer installation guidelines

Ensuring legal compliance is not just about avoiding fines; it’s about safeguarding lives and property. When installing or inspecting electrical cable without earth wire, thorough knowledge of local legal requirements is essential—an ungrounded system must always align with the highest safety standards dictated by law. This vigilance guarantees that installations remain safe, reliable, and compliant with evolving regulations.

Implications of Non-Compliance – Penalties and safety risks

In the intricate dance of electrical safety, neglecting the legal and regulatory landscape can lead to catastrophic consequences. Electrical cable without earth wire, while sometimes deemed suitable for specific applications, carries inherent risks that demand vigilant oversight. Regulatory authorities impose strict penalties for non-compliance, not merely as bureaucratic hurdles but as safeguards against potential tragedy.

Failure to adhere to local codes can result in fines, project delays, or even the disqualification of entire installations. More critically, ungrounded wiring increases the likelihood of electric shocks, fires, or equipment damage, turning what seems like a cost-saving shortcut into a perilous gamble. When deploying electrical cable without earth wire, it’s essential to understand and respect the delicate framework of safety standards that underpin modern electrical systems.

Authorities often specify that such cables are permissible only within tightly controlled parameters—be it in low-voltage lighting circuits or temporary setups. Ignoring these stipulations not only breaches legal mandates but also endangers lives. Ultimately, the true cost of non-compliance surpasses monetary penalties; it manifests in shattered trust and preventable tragedies. Vigilance in compliance ensures that the silent currents of electricity serve as a source of illumination, not a harbinger of chaos.

Professional Guidance – When to consult qualified electricians

In the labyrinthine world of electrical installations, the importance of adhering to legal and regulatory standards cannot be overstated. When contemplating the use of an electrical cable without earth wire, consulting qualified electricians becomes not just advisable but vital. Their expertise ensures that the chosen wiring complies with the intricate tapestry of safety standards mandated by authorities—standards designed to safeguard lives and property.

For complex projects or unfamiliar settings, engaging a professional can prevent costly oversights. They can evaluate whether the application falls within permitted parameters and recommend appropriate measures. In some instances, the use of an electrical cable without earth wire might be permissible—particularly in low-voltage or temporary setups—but only under strict adherence to regulations.

- Assessing voltage and load demands

- Ensuring environmental suitability

- Verifying compatibility with existing infrastructure

Ultimately, the guidance of a qualified electrician serves as a safeguard against non-compliance, which could lead to severe penalties or safety hazards. In this realm, expertise is not merely a luxury but a necessity—because when it comes to electrical safety, even the smallest detail can make all the difference.