Understanding Electrical Cable Neutral

Definition of Neutral in Electrical Systems

In the vast tapestry of electrical systems, the concept of the electrical cable neutral is often regarded as the silent guardian—an unseen force maintaining balance and safety. Without this essential component, the intricate dance of current flow would descend into chaos, risking damage and danger. The neutral acts as a return path, completing the circuit with a gentle yet vital hand, guiding excess current safely back to its origin.

Understanding the role of the electrical cable neutral is akin to exploring the mythic roots of a legendary city—its presence is subtle but indispensable. It ensures that appliances function correctly and prevents electrical faults from spiraling into catastrophic failures. In South Africa, where electrical safety standards are paramount, the neutral’s integrity preserves both life and property. The neutral is usually connected to the earth at the main distribution board, forming a vital link that stabilizes voltage and mitigates electrical shocks.

Role of Neutral Wire in Power Distribution

In the intricate realm of power distribution, the electrical cable neutral emerges as a subtle yet unwavering sentinel—an unseen force that ensures harmony within the chaos of currents. Its role extends beyond mere circuitry; it is the silent architect of stability, guiding excess electrical energy safely back to its origin. Without this vital component, the entire system risks spiraling into peril, where even a minor fault can ignite a cascade of failures and safety hazards.

Understanding the role of the neutral wire in electrical systems reveals a layered complexity: it not only completes the circuit but also stabilizes voltage levels, preventing dangerous fluctuations. In South Africa’s rigorous safety landscape, the integrity of the electrical cable neutral is paramount. It is often interconnected with earth at the main distribution board—forming a critical link that mitigates electrical shocks and maintains equilibrium across diverse electrical loads.

- Ensures safe return of current, preventing overloads.

- Stabilizes voltage within the system, safeguarding appliances.

- Provides a reference point for detecting faults, facilitating quick intervention.

Differences Between Neutral and Ground Wires

In the intricate dance of electricity, understanding the distinction between the electrical cable neutral and the ground wire reveals a profound truth about our reliance on unseen forces. While both serve crucial safety functions, their roles are fundamentally different—yet intertwined—like two sides of the same coin. The neutral wire, often overlooked, is the silent architect that completes the circuit, ensuring that current has a safe return path. Meanwhile, the ground wire acts as a vigilant sentinel, protecting us from potential faults by redirecting excess energy safely into the earth.

To grasp the nuanced differences, consider this: the electrical cable neutral is primarily responsible for stabilizing voltage and preventing overloads, whereas the ground wire’s purpose is rooted in safety and fault prevention. They work together, but their paths and functions are distinct. Recognizing this distinction is key to appreciating the delicate balance that keeps our electrical systems stable and secure, especially in a safety-conscious environment like South Africa. The integrity of the electrical cable neutral, in particular, is vital—its proper functioning can mean the difference between safety and catastrophe.

Common Types of Neutral Cables

Understanding the different types of electrical cable neutral is essential for ensuring safe and reliable power systems. In South Africa, the most common neutral cables include solid, stranded, and multi-core variants. Each type serves a specific purpose, optimizing performance across various applications.

Solid neutral cables are prized for their simplicity and durability, making them ideal for fixed installations. Stranded neutral cables, on the other hand, are more flexible, allowing for easier routing in tight spaces. Multi-core neutral cables combine multiple conductors, providing efficient solutions for complex wiring setups.

Choosing the right electrical cable neutral depends on factors like load capacity, environmental conditions, and compliance with local regulations. No matter the type, ensuring the proper functioning of the neutral wire is vital to maintain system stability and safety. Remember, the integrity of your electrical system often hinges on selecting the appropriate neutral cable for your needs.

Components and Construction of Neutral Cables

Materials Used in Neutral Wires

At the heart of every reliable electrical system lies the often-overlooked hero: the electrical cable neutral. Its components are crafted with precision to ensure safety and efficiency in power distribution across South Africa’s vibrant industries and homes. The core of a neutral cable typically comprises copper or aluminum conductors, chosen for their excellent conductivity and durability. These materials are meticulously insulated with high-quality compounds that withstand harsh environmental conditions, ensuring longevity and safety.

Materials used in neutral wires are not chosen lightly; they are selected for their ability to resist corrosion and thermal stress. Copper, with its superior electrical conductivity, is the preferred choice for many applications, while aluminum offers a cost-effective alternative. The construction of the neutral cable often involves layered insulation and protective sheathing, safeguarding the conductive core from mechanical damage and moisture intrusion. This thoughtful design ensures that the electrical cable neutral performs flawlessly, maintaining the delicate balance of safe electrical flow in every installation.

Design and Insulation of Neutral Cables

The components and construction of an electrical cable neutral are engineered with meticulous care to ensure both safety and durability. Central to this design is the conductive core, typically made from copper or aluminum, chosen for their outstanding electrical properties. These materials are carefully layered with insulation compounds that serve as the first line of defense against environmental hazards. Insulation not only prevents accidental contact but also resists thermal stress and corrosion, which are common challenges in South Africa’s diverse climate.

To enhance protection, neutral cables often feature a robust protective sheathing that shields against mechanical damage and moisture intrusion. This outer layer is essential for maintaining the integrity of the electrical cable neutral, especially in rugged rural settings where exposure to harsh elements is inevitable. The thoughtful construction of these cables ensures that the neutral component performs reliably, safeguarding the flow of electricity and supporting the seamless operation of homes and industries alike. The design intricacies behind each neutral cable underscore its importance in maintaining a safe and efficient electrical system across South Africa’s vibrant landscape.

Color Coding and Identification

In the intricate dance of power distribution, the electrical cable neutral plays a vital role, and its components are nothing short of engineered marvels. At the core of every neutral cable is a conductive material—copper or aluminum—chosen for their exceptional electrical conductivity and durability. Surrounding this core, high-quality insulation compounds act as the first line of defense, preventing environmental damage and ensuring safety in South Africa’s diverse climate.

One often overlooked yet critical aspect of the electrical cable neutral is its color coding and identification. Proper color coding isn’t just about aesthetics; it’s a safeguard that ensures quick and accurate identification during installation and maintenance. Typically, neutral wires are identified by specific color codes such as white or grey in many regions, but in South Africa, these may vary depending on local standards. To avoid confusion, many professionals rely on a combination of color coding and clear labeling, which is essential when working in complex wiring systems.

For added protection, neutral cables commonly feature a robust protective sheathing that shields against mechanical damage and moisture intrusion. This outer layer is vital, especially in rural South African environments where exposure to elements is relentless. The thoughtful construction of these cables ensures the reliability of the electrical cable neutral, safeguarding the flow of electricity and maintaining system integrity across all types of installations.

Variations in Neutral Cable Construction

Every electrical cable neutral is a meticulously engineered component, designed to ensure safety and efficiency in power systems. Its construction varies depending on specific application requirements, environmental conditions, and regulatory standards. At the heart of most neutral cables lies a core conductor made from copper or aluminum—materials renowned for their exceptional electrical conductivity and resilience. Surrounding this core, insulation compounds are carefully selected to provide optimal protection against environmental factors, mechanical stress, and moisture intrusion.

Variations in neutral cable construction often reflect the unique needs of South African installations. Some cables feature a single solid conductor, ideal for stable environments, while others incorporate stranded conductors for increased flexibility in complex wiring systems. Additionally, protective sheathing can differ in thickness and material, tailored to withstand harsh outdoor conditions or demanding industrial environments. Here’s a quick overview:

- Solid core conductors for straightforward, fixed installations

- Stranded conductors for enhanced flexibility and ease of installation

- Durable outer sheathing to resist mechanical damage and moisture

The choice of construction impacts not only the cable’s durability but also its electrical performance, making it a crucial consideration for professionals working with electrical cable neutral in South Africa. Every component, from the conductive core to the outer sheath, plays a vital role in maintaining system integrity and safety across diverse applications.

Installation and Connection of Neutral Cables

Best Practices for Neutral Wire Installation

Proper installation of the electrical cable neutral is crucial to ensure safe and reliable power distribution. When connecting the neutral wire, it’s essential to follow best practices that prevent faults and reduce the risk of electrical shock.

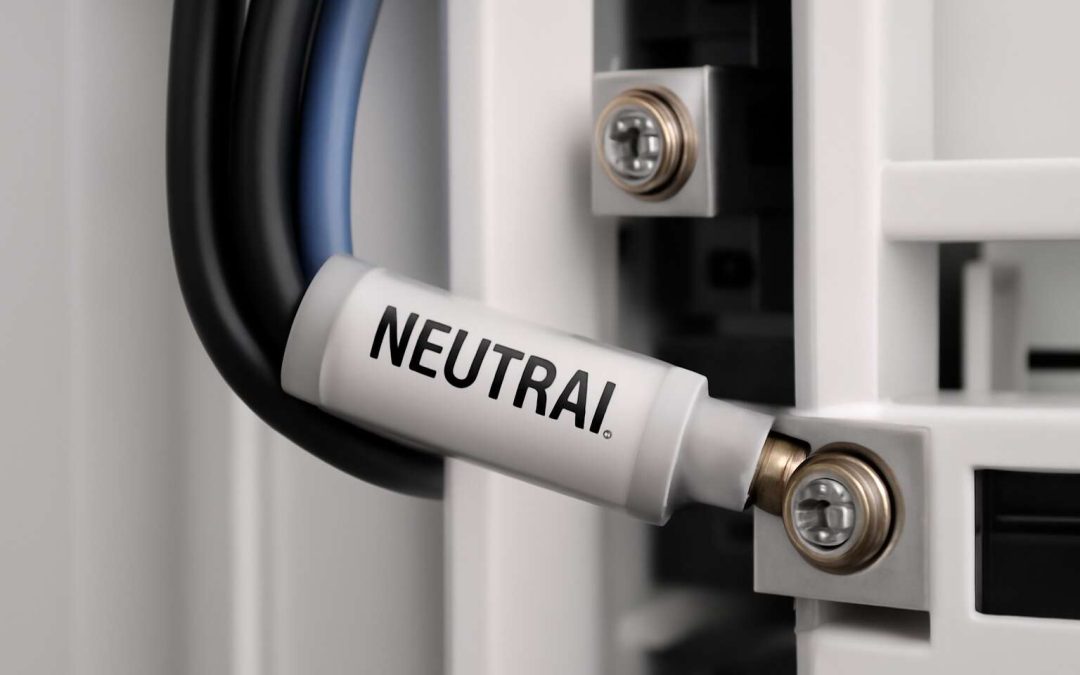

First, always verify that the neutral wire is correctly identified using standard color coding and insulation. This step minimizes errors during connection. When installing the neutral cable, ensure it is securely fastened to the terminal or busbar, avoiding loose connections that can generate electrical arcing or heat buildup.

In complex systems, consider the use of dedicated neutral terminals or connectors to maintain system integrity. For added safety, use proper tools and wear personal protective equipment. If multiple neutral cables are involved, follow an organized wiring scheme, such as the one outlined in the list below, to keep connections clear and accessible:

- Turn off power at the main supply.

- Identify the neutral wire using color codes or markings.

- Securely connect the neutral cable to the designated terminal.

- Ensure all connections are tight and insulated properly.

- Switch the power back on and test the system for continuity and safety.

Adhering to these best practices guarantees the integrity of your electrical system and prolongs the lifespan of your neutral wiring.

Connection Techniques and Terminations

Connecting the electrical cable neutral is more than a simple task; it’s a delicate act that demands precision, integrity, and an understanding of the system’s subtle rhythm. When installing or terminating the neutral cable, every contact point must be a testament to meticulous craftsmanship. Loose connections are not just technical errors—they are the cracks through which chaos can seep into your power system, risking faults or electrical shocks.

Proper connection techniques involve ensuring that the neutral wire is firmly secured to the designated terminal or busbar. In complex systems, consider the use of dedicated neutral terminals, which help maintain system stability and safety. For clarity and safety, follow an organized wiring scheme:

- Turn off power at the main supply.

- Identify the neutral wire using color codes or markings.

- Securely connect the neutral cable to its designated terminal.

- Double-check that all connections are tight and properly insulated.

- Restore power and perform continuity tests to confirm safety and proper function.

Attention to detail in the connection of the electrical cable neutral is what transforms a mere wiring task into a safeguard for lives and equipment. It’s in these precise moments that the integrity of your system is forged, ensuring it withstands the tests of time and human error.

Neutral Bus Bars and Panels

The installation and connection of neutral cables to bus bars and panels is a critical juncture in ensuring the safety and reliability of any electrical system. In South Africa, where power stability can be unpredictable, meticulous attention to this process becomes even more vital. When installing an electrical cable neutral, it’s essential to follow precise procedures that uphold system integrity and prevent future faults.

Neutral bus bars serve as the central hub for multiple neutral cables, providing a common grounding point that simplifies wiring and enhances safety. Proper connection involves securing the neutral cable firmly to the bus bar, ensuring no loose contacts that could lead to electrical arcing or system instability. Consider using dedicated neutral terminals within panels; these are designed to handle the current load and facilitate easier maintenance.

For optimal wiring, follow an organized approach:

- Turn off power at the main supply to prevent accidental contact.

- Identify the neutral cable using recognized color coding, typically white or grey.

- Securely connect the neutral cable to its designated terminal or bus bar, ensuring a tight fit.

- Double-check insulation and connection stability before restoring power.

In complex electrical systems, the use of well-designed neutral bus bars and panels can significantly reduce the risk of faults. It’s in these connections that the harmony of your electrical network is forged, underpinning both safety and performance. Every neutral connection made with care becomes a silent guardian—protecting lives, safeguarding equipment, and ensuring uninterrupted power flow across South Africa’s diverse energy landscape.

Safety Precautions During Installation

In the heart of South Africa’s bustling towns and quiet rural homesteads, the installation of an electrical cable neutral demands both precision and respect. Every neutral connection is a vital thread in the intricate fabric of power distribution, silently safeguarding lives and livelihoods. When working with an electrical cable neutral, safety precautions are not mere suggestions—they are non-negotiable. Ensuring the power is turned off at the main supply before handling neutral cables prevents accidental shocks, a risk that can have devastating consequences. Properly identifying the neutral wire, often distinguished by its color coding, helps avoid costly mistakes that could compromise system safety.

During installation, take the time to double-check each connection, making sure the neutral cable is firmly secured to the bus bar or terminal. Loose connections can cause arcing or future faults, threatening both equipment and safety. The process of connecting an electrical cable neutral is as much about patience and care as it is about technical skill; every step must be executed with deliberate attention. When done correctly, these connections become the quiet guardians of your electrical system—ensuring stability, safety, and peace of mind across South Africa’s diverse energy landscape.

Common Issues and Troubleshooting

Neutral Wire Faults and Failures

Faulty electrical cable neutral connections can cause a cascade of problems, from flickering lights to dangerous electrical shocks. One common issue is a loose or corroded neutral wire, which disrupts the balance of the electrical system and leads to voltage fluctuations. These faults are often hidden behind walls or within panels, making them tricky to detect without proper inspection.

Troubleshooting neutral wire faults involves systematic checks—starting with inspecting connections for looseness or corrosion, then testing continuity with a multimeter. In some cases, the neutral wire may be damaged or broken, requiring replacement. Remember, a compromised electrical cable neutral can also cause electrical appliances to malfunction or overheat, posing safety risks.

In South Africa, where infrastructure varies widely, understanding the typical signs of neutral failure—such as unexpected power loss or unusual electrical noise—becomes vital. Addressing these issues promptly ensures safety and prevents costly damage, emphasizing the importance of proper installation and regular inspection of the electrical cable neutral.

Symptoms of Neutral Wiring Problems

Electrical cable neutral issues are often the silent saboteurs of a smoothly functioning electrical system. You might not see them, but their symptoms can be glaring—flickering lights, appliances that behave like they’re possessed, or unexpected power outages. Recognizing these symptoms early is crucial to avoiding costly repairs and potential safety hazards.

Troubleshooting electrical cable neutral problems involves a keen eye and a multimeter’s touch. Loosened or corroded neutral wire connections are common culprits, causing unpredictable voltage fluctuations that leave homeowners scratching their heads. Sometimes, the neutral wire itself may be broken or damaged, requiring prompt replacement.

Keep an eye out for signs like electrical noise—buzzing or humming sounds—and inconsistent power delivery. These hints often point to a compromised electrical cable neutral. Addressing these issues quickly can save you from dangerous shocks or appliance damage, especially in South Africa’s diverse infrastructure landscape.

Diagnostic Tools for Neutral Testing

When troubleshooting electrical cable neutral issues, understanding the common problems that plague these vital components can prevent costly repairs and dangerous situations. One of the most frequent culprits is a loose or corroded neutral connection, which can cause unpredictable voltage fluctuations and erratic appliance behavior. Over time, environmental factors such as moisture and corrosion can weaken the integrity of the neutral wire, leading to intermittent faults. Recognizing these issues early is essential for maintaining a safe and reliable electrical system.

Diagnostic tools are indispensable in identifying neutral wiring problems with precision. A multimeter, for instance, allows a technician to measure voltage levels across the electrical cable neutral and hot wires. During testing, a safe approach involves checking for voltage differences that deviate from the standard 230V in South Africa. If irregularities are detected, further investigation is warranted.

- Using a continuity tester to verify the integrity of the neutral wire;

- Employing a clamp meter to detect current flow anomalies;

- Conducting visual inspections for signs of wear, corrosion, or damage.

These methods ensure that neutral faults are diagnosed accurately, enabling timely repairs and safeguarding your electrical system’s health.

Solutions and Repair Tips

In the intricate dance of electricity, the electrical cable neutral often assumes the silent role of a dependable conductor—yet, its fragility can be hidden beneath the surface. When troubles arise, they often manifest as flickering lights, sudden power surges, or appliances behaving unpredictably. These symptoms are more than mere inconveniences; they are siren calls warning of underlying issues within the neutral connection.

Common issues with the electrical cable neutral include loose connections, corrosion, or damage from environmental elements. Such faults can cause erratic voltage levels, posing safety risks and impairing system efficiency. Troubleshooting begins with a keen eye—visual inspections for signs of wear, corrosion, or broken insulation, combined with diagnostic tools like multimeters and clamp meters. These instruments serve as the detective’s magnifying glass, revealing hidden faults with precision.

- Loose neutral connections

- Corrosion or rust on neutral wires

- Physical damage or wear from environmental exposure

Proper identification and swift repairs are vital to restore the harmony of your electrical system.

When faced with persistent issues, consider inspecting the neutral wire’s connection points and ensuring that all terminations are secure. Faulty neutral wiring can cause unexpected current flow anomalies, which a skilled technician can detect using specialized diagnostic tools. Repairing the neutral requires not only technical know-how but also a meticulous approach to prevent future failures. Remember, a compromised neutral is more than an inconvenience; it’s a potential hazard lurking silently within your electrical network. Addressing these issues promptly preserves the reliability and safety of your electrical infrastructure, safeguarding both property and lives.

Regulations and Standards for Neutral Cables

IEEE and IEC Standards

In the realm of electrical safety and efficiency, adherence to rigorous standards is non-negotiable. Regulations governing the use of electrical cable neutral are meticulously outlined in both IEEE and IEC standards, ensuring uniformity and reliability across installations. These standards set the blueprint for proper neutral wiring, insulation, and connection techniques that prevent faults and enhance system stability.

Specifically, IEC standards emphasize the importance of clear color coding and insulation requirements for neutral conductors, which is vital for quick identification and safety during maintenance. Meanwhile, IEEE guidelines focus on grounding and fault protection to minimize risks associated with neutral wire failures. For professionals working within South Africa, understanding how these international standards align with local regulations is crucial. They guarantee that the electrical cable neutral functions flawlessly, safeguarding both personnel and equipment from unforeseen electrical hazards.

National Electrical Code (NEC) Guidelines

Regulations surrounding the electrical cable neutral are the backbone of safe and reliable electrical installations. In South Africa, adherence to the National Electrical Code (NEC) and local amendments ensures that neutral wiring meets strict safety standards. These regulations specify how neutral cables must be correctly installed, insulated, and connected to prevent faults and electrical hazards.

Understanding these guidelines is essential for professionals aiming to maintain system integrity. The NEC emphasizes proper grounding and fault protection, which directly impacts the performance of the electrical cable neutral. Compliance with these standards not only minimizes risks but also guarantees the longevity of electrical systems. For example, correct connection techniques and adherence to insulation requirements safeguard personnel and equipment alike.

Compliance and Safety Regulations

Within the shadowed corridors of electrical craftsmanship, the regulation of the electrical cable neutral stands as a silent sentinel guarding life and limb. South Africa’s adherence to the strict mandates of the National Electrical Code (NEC) is not merely bureaucratic ritual but a vital covenant that ensures safety and stability in every wire spun and connection forged. These standards dictate the precise manner in which the electrical cable neutral must be installed—insulated flawlessly, connected with unwavering accuracy, and protected against the sinister specters of faults and shorts.

In the realm of compliance, certain principles emerge from the darkness—among them, the necessity to uphold rigorous grounding practices and fault protection measures. These are not mere formalities but the very lifeblood that sustains the integrity of the electrical system.

- Proper connection techniques

- Insulation requirements

are the arcane runes that safeguard personnel and equipment alike, ensuring that the electrical cable neutral remains a pillar of reliability rather than a harbinger of chaos. In this dance of safety and precision, regulations serve as the guiding star, illuminating the path through the labyrinth of electrical standards.

Impact of Regulations on Neutral Cable Selection

In the world of electrical systems, the significance of adhering to strict regulations and standards cannot be overstated. The electrical cable neutral, often overlooked, plays a pivotal role in maintaining safety and system stability. South Africa’s compliance with international standards such as the IEC (International Electrotechnical Commission) guidelines ensures that every installation upholds the highest safety benchmarks.

Regulations shape the selection and installation of neutral cables profoundly. They dictate specific requirements for insulation, conductor material, and connection methods, ensuring that the electrical cable neutral functions reliably under all conditions. For example, standards emphasize the importance of using appropriately rated neutral cables to prevent overheating and faults. This is especially vital in high-load environments, where the integrity of the neutral connection can be a matter of life or death.

Impact of regulations on neutral cable selection is clear: choosing the right cable type, size, and insulation is not optional but mandatory. Compliance ensures that electrical systems are protected against faults and short circuits, reducing the risk of failure. It also influences the choice of protective devices and grounding methods, further safeguarding personnel and property. In essence, regulations serve as the blueprint for making informed, safe choices about the electrical cable neutral, weaving safety into every strand of electrical infrastructure.

Choosing the Right Neutral Cable for Your Project

Factors to Consider (Current Load, Compatibility)

Choosing the right electrical cable neutral for your project can be the difference between seamless power distribution and costly setbacks. One of the primary factors to consider is the current load your electrical system will carry. Overloading a neutral cable can lead to overheating and potential failure, so understanding your project’s power demands is crucial.

Compatibility also plays a significant role. Not all neutral cables are suited for every application—different materials and construction styles are designed for specific voltage levels and environmental conditions. Ensuring that your neutral cable matches the system’s specifications helps maintain safety and efficiency.

To simplify your decision-making process, consider these key factors:

- Assess the maximum current load expected during peak operation.

- Verify compatibility with your existing electrical infrastructure.

- Check for compliance with local standards and regulations.

When selecting an electrical cable neutral, paying close attention to these aspects ensures your installation remains reliable and safe, preventing future complications that could arise from improper choices.

Different Types of Neutral Cables for Residential and Commercial Uses

Choosing the right electrical cable neutral can be a game-changer in ensuring the safety and efficiency of your electrical system. Different types of neutral cables are tailored for specific applications, whether residential or commercial. For high-demand settings, stranded copper neutral cables are often preferred due to their superior conductivity and flexibility, making installation smoother and more reliable. Conversely, for lighter loads, solid core neutral cables may suffice, offering durability and cost-effectiveness.

In South Africa, the choice of neutral cable material and construction is crucial, especially considering local standards and environmental factors. The right neutral cable must not only match the voltage requirements but also withstand moisture, temperature fluctuations, and potential mechanical stress.

Understanding the distinctions between various neutral cable types helps prevent future failures. For instance, armored neutral cables provide added protection in harsh environments, while PVC-insulated options are suitable for indoor applications. When selecting an electrical cable neutral, assessing these factors ensures your installation remains resilient and compliant with local safety regulations.

Environmental Considerations

Choosing the right electrical cable neutral is essential for ensuring safety and durability in your South African project. Environmental factors can significantly impact the performance of neutral cables, especially in areas prone to high humidity, temperature fluctuations, or mechanical stress. Selecting a neutral cable that resists moisture and extreme temperatures helps prevent failures and extends the lifespan of your electrical system.

In regions with harsh conditions, armored neutral cables provide extra protection against physical damage, while PVC-insulated options are ideal for indoor use. It’s important to evaluate your specific environment and load requirements before selecting the appropriate neutral cable. For outdoor or industrial settings, durability becomes a top priority, and using the correct material and construction can make all the difference.

- Assess environmental conditions such as moisture, temperature, and mechanical stress.

- Choose neutral cables with suitable insulation and protective features.

- Ensure compatibility with local standards and safety regulations.

Understanding these environmental considerations ensures your electrical cable neutral withstands the challenges of its setting, providing reliable, safe power distribution long-term.

Cost and Budgeting

Choosing the right electrical cable neutral is a delicate dance between budget constraints and the promise of long-lasting safety. In South Africa’s vibrant landscape, where conditions can vary from lush coastal humidity to arid inland heat, selecting an affordable yet reliable neutral cable becomes paramount. While budget-friendly options might seem tempting, they often lack the durability needed to withstand environmental stresses.

Opting for neutral cables with high-quality insulation and protective features can initially seem more costly but pays dividends over time. For projects with tight budgets, consider prioritizing materials that resist moisture and temperature fluctuations—these qualities are essential for maintaining system integrity. Remember, investing in the correct neutral cable not only safeguards your project but also ensures it remains resilient against unforeseen challenges, making safety and economy go hand in hand.

Future Trends in Neutral Cable Technology

Innovations in Materials and Design

The future of electrical cable neutral technology is poised for remarkable evolution, driven by innovative materials and design breakthroughs. As energy demands grow and sustainability becomes paramount, manufacturers are exploring new composites that enhance conductivity while reducing environmental impact. These advancements promise neutral wires that are not only more efficient but also more durable, capable of withstanding extreme South African climates—from scorching desert heat to humid coastal air.

Design innovations are also gaining momentum, with a focus on modularity and smart integration. For instance, the development of flexible neutral cables with embedded sensors allows for real-time monitoring of load and fault conditions, significantly improving safety and maintenance. Additionally, alternative insulation materials, such as biodegradable polymers, are being tested to align with eco-conscious standards. These innovations will undoubtedly shape the landscape of electrical systems, ensuring that the humble electrical cable neutral continues to evolve in tandem with our modern needs.

Smart and Shielded Neutral Cables

As South Africa’s energy landscape evolves, the future of electrical cable neutral technology promises to be as dynamic as our vibrant landscapes. With increasing demand for smarter, safer electrical systems, the advent of smart and shielded neutral cables is nothing short of revolutionary. These innovations are designed to meet the rigorous standards of modern infrastructure while seamlessly integrating into existing networks.

Smart neutral cables, embedded with sensors, enable real-time monitoring of load conditions and fault detection, transforming maintenance from reactive to proactive. Shielded neutral cables, on the other hand, offer enhanced protection against electromagnetic interference, ensuring reliable power delivery even in the most challenging environments. This is particularly vital in South Africa, where fluctuating weather conditions can wreak havoc on electrical systems. Incorporating these advanced features not only elevates safety but also extends the lifespan of electrical cable neutral components, making them an indispensable part of future-proof electrical installations.

To illustrate the trend, consider the following innovations in neutral cable technology:

- Integration of IoT sensors for remote diagnostics

- Enhanced shielding materials for electromagnetic resilience

- Use of biodegradable insulation to promote environmental sustainability

With these technological strides, electrical cable neutral systems are poised to become more resilient, efficient, and eco-conscious—an evolution that aligns perfectly with South Africa’s pursuit of sustainable energy solutions. The future is undeniably bright for neutral wiring, where innovation and reliability walk hand in hand.

Integration with Renewable Energy Systems

In the shadowed corridors of South Africa’s burgeoning energy future, the integration of renewable systems beckons a new era of electric innovation. The electrical cable neutral, long a silent guardian of power distribution, now takes on a more vital role—adapting to the demands of sustainable energy. As solar farms and wind turbines carve into the landscape, the need for resilient, intelligent neutral wiring becomes paramount.

Emerging trends suggest that future neutral cables will be woven with IoT sensors, enabling remote diagnostics that preempt failures before they manifest. These sensors act like vigilant sentinels, watching over load conditions and detecting faults with an eerie precision. Shielded neutral cables, crafted with enhanced materials, resist electromagnetic interference—crucial in environments where fluctuating weather can distort power signals.

As the push towards eco-conscious solutions intensifies, biodegradable insulation materials will likely become standard, reducing the environmental footprint of electrical infrastructure. This convergence of technology and sustainability signals a future where the electrical cable neutral is no longer just a passive component but an active participant in the pursuit of resilient, renewable energy systems.

- Integration of IoT sensors for real-time system health monitoring

- Advanced shielding materials for electromagnetic resilience

- Use of biodegradable insulation to foster environmental sustainability

With each innovation, the electrical cable neutral evolves—becoming more than a mere conduit, but a lifeline that ensures stability in South Africa’s energy landscape, even amid the most tumultuous atmospheric conditions. This is the dawn of an era where the silent power of the neutral wire becomes a beacon of progress, guiding us into a cleaner, smarter future.

Emerging Standards and Best Practices

As the electrical landscape in South Africa evolves, so too does the future of the electrical cable neutral. Emerging standards are pushing the boundaries of what was once considered standard practice, aiming to enhance safety, efficiency, and environmental sustainability. In this age of rapid technological advancement, it’s no longer enough for the neutral wire to simply carry current; it must do so intelligently and resiliently.

Innovations in neutral cable technology are now prioritizing integration with renewable energy systems. Future neutral cables will likely incorporate IoT sensors, offering real-time diagnostics and predictive maintenance capabilities. This means potential faults can be identified before they become costly repairs—an essential feature in the unpredictable South African climate. Furthermore, the adoption of advanced shielding materials enhances electromagnetic resilience, reducing interference and ensuring consistent power delivery.

In addition to technological strides, regulatory standards are becoming more stringent. An increasing number of industry bodies are advocating for the use of biodegradable insulation materials, aligning with global environmental goals. Such standards not only promote eco-conscious practices but also set the stage for the development of neutral cables that are both durable and environmentally friendly.

Looking ahead, it’s clear that the future of the electrical cable neutral lies in a harmonious blend of innovation and regulation. With these new standards, the neutral wire is poised to become more than just a conduit—it’s set to become a cornerstone of smart, sustainable power infrastructure.