Understanding Electrical Cable Gauge

What Is Cable Gauge? – Definition and importance of cable gauge in electrical wiring

Electrical cable gauge might not be the most glamorous aspect of wiring, but it’s undeniably critical. It determines how much current a cable can safely carry without overheating or causing hazards. Choosing the correct electrical cable gauge ensures safety, efficiency, and longevity of your electrical system. In South Africa, where power demands are constantly rising, understanding this measurement can make all the difference.

What exactly is cable gauge? It’s a standardized way to measure the thickness or diameter of a wire. Larger gauges mean thicker wires, capable of handling higher currents. Conversely, smaller gauges are suitable for lighter loads but can pose risks if used improperly. The importance of selecting the right electrical cable gauge cannot be overstated—it’s fundamental to preventing electrical failures and ensuring compliance with local standards.

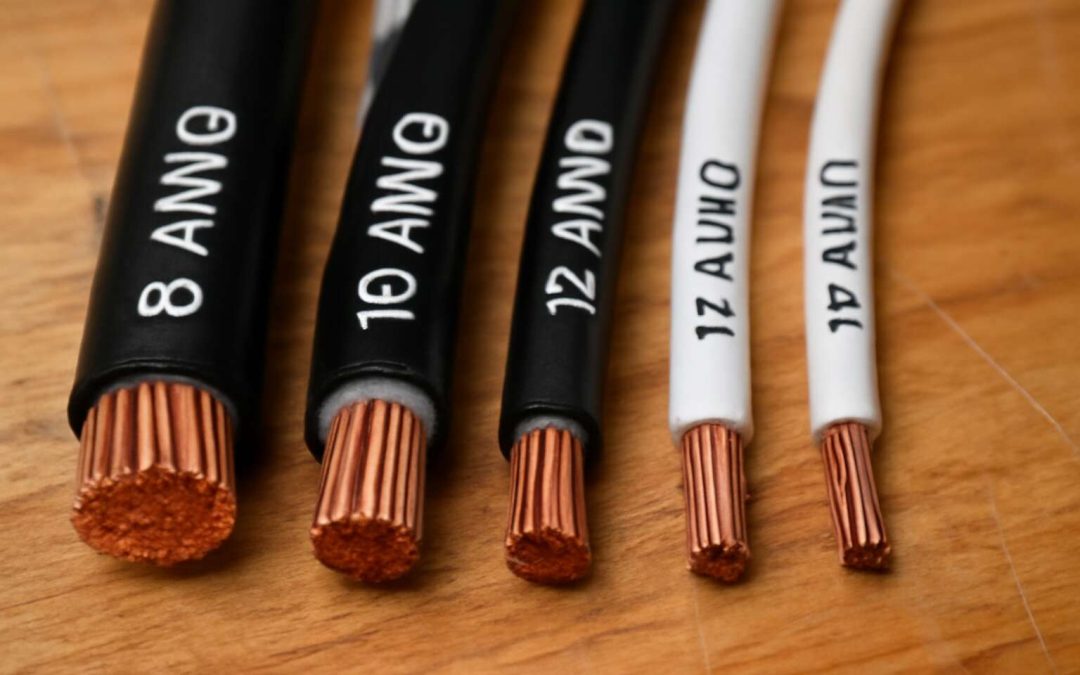

To simplify, here’s a quick overview of common gauge sizes:

- 12 AWG – suitable for general household circuits.

- 10 AWG – used for appliances drawing more power.

- 14 AWG – ideal for low-power fixtures.

Choosing the proper electrical cable gauge is not just about convenience. It’s about safety and efficiency, especially in environments like South Africa where power reliability can vary. Proper gauge selection guarantees your wiring is up to standard and ready to handle the load.

History and Evolution of Cable Gauges – Brief overview of how gauge standards have developed over time

The story of electrical cable gauge is one of constant evolution, shaped by technological progress and the growing demands of everyday life. In the early days of electrical wiring, standards varied wildly, and gauges were often determined by simple wire gauge charts that lacked uniformity. Over time, as electricity became more integral to our homes and industries, the need for standardized measurements became clear. This led to the development of the American Wire Gauge (AWG) system, a method that introduced consistency and precision to wiring practices.

Today, the electrical cable gauge is a crucial aspect of safe electrical systems. The standards have been refined through decades, ensuring that wires can safely carry increasing loads without overheating. The evolution of these gauges reflects a broader commitment to safety and efficiency, especially in regions like South Africa, where power demands are surging. The adoption of uniform gauge measurements makes it easier for electricians and homeowners alike to select the right wire for every application, from household circuits to heavy-duty appliances.

Types of Electrical Cables and Their Gauges

Residential Wiring – Typical gauges used in home electrical systems

Electrical cables are the silent backbone of every home, especially in the heart of South Africa where rural life relies heavily on sturdy, reliable wiring. When choosing the right electrical cable gauge, understanding the different types of cables and their gauges becomes essential. Residential wiring typically demands specific gauges to ensure safety and efficiency. For example, a common electrical cable gauge for lighting circuits is 1.5mm², while power outlets often require a thicker gauge like 2.5mm² to handle higher currents. The right gauge prevents overheating and ensures longevity, which is vital for rural households that depend on consistent electricity.

In rural South Africa, where electrical infrastructure can be varied, selecting the correct electrical cable gauge is more than a technical choice—it’s a safeguard for everyday life. Whether installing new wiring or upgrading existing systems, understanding the nuances of gauges ensures that homes remain safe and functional. The importance of choosing the right electrical cable gauge cannot be overstated, especially in areas where access to emergency services may be limited, yet the need for dependable power is constant.

Commercial and Industrial Applications – Gauges for heavy-duty applications

In the realm of commercial and industrial electrical systems, the choice of electrical cable gauge is critical for safety and performance. Heavy-duty applications demand cables that can handle substantial currents without overheating or compromising structural integrity. Unlike residential wiring, where modest gauges suffice, industrial environments require robust gauges such as 16mm², 25mm², or even larger, depending on the load. These thicker cables ensure efficient power transmission over long distances, reducing voltage drops and maintaining system stability.

For high-power applications like manufacturing plants, data centers, or large-scale machinery, selecting the correct electrical cable gauge isn’t just about capacity—it’s about safeguarding lives and assets. The gauge determines how much current the cable can carry safely, preventing potential hazards. When dealing with such demanding environments, understanding the nuances of cable gauges—be it for heavy-duty power distribution or specialized equipment—is essential to keep operations running smoothly and safely.

Underground and Exterior Wires – Special gauge considerations for outdoor use

When it comes to outdoor and underground wiring, choosing the right electrical cable gauge isn’t just a matter of plugging in and hoping for the best—it’s about ensuring durability, safety, and efficiency in the harshest conditions. Unlike indoor cables that can get away with a lighter touch, outdoor wires face the elements: moisture, UV rays, and temperature extremes. That’s why special gauge considerations are essential for underground and exterior wires.

For outdoor applications, thicker gauges such as 10mm² or 16mm² are common, providing the capacity to handle long runs without excessive voltage drops. These cables often feature robust, weather-resistant sheathing—think of it as armor for your electrical nerves. When selecting an electrical cable gauge for outdoor use, it’s crucial to consider not only the current load but also the environment’s unique challenges.

Here’s a quick rundown of typical gauges used in exterior wiring:

- 10mm² for general outdoor power feeds

- 16mm² or larger for high-power setups such as garden lighting or pumps

- Specialized UV-resistant and waterproof cables for exposed runs

Remember, the right gauge and quality of outdoor electrical cables can mean the difference between a reliable system and a costly, hazardous failure. It’s always wise to consult local standards and expert advice when planning underground or exterior wiring projects—after all, safety and efficiency should never be optional in the electrifying world of electrical cable gauge choices.

How to Choose the Right Electrical Cable Gauge

Load Requirements – Calculating electrical load and selecting appropriate gauge

Choosing the right electrical cable gauge is akin to selecting the perfect steed for a grand quest; it must be strong enough to carry the load yet agile enough to navigate the treacherous terrain of electrical demands. When embarking on this journey, the first step is to meticulously calculate the electrical load that your project will demand. This involves summing the wattage of all devices and appliances that will draw power, ensuring no detail is overlooked. Once the load is known, the magic truly begins — selecting an appropriate electrical cable gauge that can handle this burden without risking overheating or voltage drops.

For safety and efficiency, it is essential to understand that a smaller gauge number signifies a thicker cable capable of carrying higher currents. In practical terms, this means that a 2-gauge cable might be needed for a heavy-duty workshop, whereas lighter circuits in a residential setting could require only 14 or 16 gauge. When determining the optimal gauge, consider the distance the current must travel, as longer runs demand thicker cables to compensate for voltage loss. By aligning load requirements with the appropriate electrical cable gauge, you ensure your electrical system remains robust, resilient, and ready to face any challenge that comes its way!

Wire Length and Voltage Drop – Impact of wire length on gauge choice

As currents weave through the labyrinth of wires beneath our feet, the influence of wire length on electrical cable gauge becomes an unspoken truth. Longer runs, whether threading through a sprawling workshop or an expansive outdoor setup, demand a more substantial gauge to mitigate voltage drop and preserve the integrity of power delivery. The subtle dance between length and gauge shapes the resilience of your electrical system, ensuring it remains steadfast against the relentless march of electrical demands.

Understanding this relationship is crucial—an undersized cable can lead to overheating and inefficiency, while an oversized one might be unnecessarily costly. When selecting the right electrical cable gauge, consider the distance the electric current must travel. For instance, a 50-meter run in a high-demand environment might necessitate a thicker gauge than a shorter, lighter circuit. In practical terms, this means paying close attention to the specific load requirements and the environment in which the wire will operate.

- Longer wire runs increase resistance, which can cause voltage drops

- Thicker gauge cables reduce resistance, maintaining voltage levels

- Choosing the right gauge balances safety, efficiency, and cost

In the pursuit of electrical excellence, the impact of wire length on gauge choice is an essential piece of the puzzle—one that ensures your electrical installation remains both robust and resilient, capable of standing firm amidst the shifting currents of modern life.

Material Considerations – Copper vs. aluminum wiring and their gauge differences

When choosing the right electrical cable gauge, material considerations are paramount. Copper wiring remains the gold standard for most applications due to its excellent conductivity and durability. It allows for thinner gauges while delivering reliable performance, making it a cost-effective choice for many installations. Aluminum wiring, on the other hand, offers a lighter, more affordable alternative, but it typically requires a thicker gauge to handle the same current. This is because aluminum has higher resistance, meaning it’s less efficient than copper for conducting electricity.

Understanding the differences in gauge for copper versus aluminum wiring can prevent costly mistakes. For high-demand environments or long runs, selecting the appropriate electrical cable gauge tailored to the material can significantly impact safety and efficiency. Remember, thicker gauges in aluminum wiring help counteract its higher resistance but may increase material costs. In contrast, copper’s superior conductivity often means smaller, more manageable gauges, though at a higher initial price. Balancing these factors ensures your electrical system remains resilient and efficient, no matter the material used.

Safety and Compliance – Standards and codes influencing gauge selection

Choosing the right electrical cable gauge isn’t just a matter of picking a number out of a hat; it’s a critical decision that influences safety, efficiency, and compliance with strict standards. In South Africa, regulations like SANS 10142 set the gold standard for electrical installations, ensuring that the gauge selected can handle the load without overheating or risking fire.

Safety and adherence to local codes are non-negotiable. A cable gauge that’s too thin for the current can lead to dangerous heat buildup, while an oversized gauge might blow your budget with unnecessary material costs. It’s essential to consult the relevant standards and match the electrical cable gauge precisely to the application’s demands. Remember, when it comes to wiring, a little extra thickness in your cables can be a lifesaver—literally!

For those venturing into complex setups, consider the load requirements and the impact of wire length on voltage drop. Proper gauge selection ensures reliable power delivery and peace of mind, making your electrical system a well-oiled machine rather than a ticking time bomb.

Understanding American Wire Gauge (AWG)

What Is AWG? – Explanation of American Wire Gauge system

Imagine a universe where every wire, every electrical current, flows seamlessly through a conduit designed with precision and purpose. That’s the magic behind understanding the American Wire Gauge (AWG) system—a numerical language that deciphers the strength and capacity of electrical cables. The AWG system is a standardized method used primarily in North America to measure the diameter of electrical cable gauge, ensuring consistency across a myriad of applications. As the gauge number decreases, the wire’s diameter increases, allowing it to carry higher electrical loads with ease. This inverse relationship might seem counterintuitive, but it’s the key to selecting the right cable for any project. When choosing an electrical cable gauge, knowing this system unlocks a world of possibilities—helping you prevent overheating and ensure safety while optimizing performance. In essence, AWG acts as the blueprint for safe, efficient, and reliable wiring—an invisible hero in every electrical masterpiece.

Gauge Numbering and Diameter – How gauge numbers correspond to wire diameter

Imagine a world where the silent language of electricity is written in numbers—each one whispering secrets about the strength and capacity of a wire. This is the essence of understanding the American Wire Gauge (AWG) system, a numerical code that reveals the true nature of electrical cable gauge. As the gauge number decreases, the wire’s diameter grows, allowing it to carry more current and power heavier loads. This inverse relationship might seem counterintuitive at first, but it’s the key to unlocking safe and efficient wiring choices.

In practice, the electrical cable gauge determines not only how much current a wire can handle but also influences safety and performance. For example, a 12-gauge wire in South Africa might be perfect for household circuits, while industrial settings demand thicker, lower gauge cables. Recognizing how gauge numbers correspond to wire diameter ensures seamless compatibility across various electrical applications. Such knowledge is vital for avoiding hazards like overheating and ensuring compliance with safety standards, making the electrical cable gauge an invisible yet essential hero in every electrical installation.

Current Capacity and Ampacity – How gauge affects current-carrying capacity

Understanding the American Wire Gauge (AWG) system is like deciphering the secret code of electrical wiring. It’s a numerical language that tells you how much current a wire can handle without throwing a tantrum or, worse, starting a fire. The gauge number directly impacts the wire’s **current capacity** or ampacity—think of it as a wire’s ability to carry a hefty load without overheating.

As a rule of thumb, lower gauge numbers mean thicker, beefier wires capable of supporting more amperes. For example, a 10-gauge wire can typically handle up to 30 amps, making it suitable for heavy-duty appliances or industrial machinery. Conversely, a higher gauge like 14 or 16 is perfect for light fixtures or low-power devices. Recognizing how your **electrical cable gauge** influences current capacity helps prevent dangerous overloads and ensures compliance with safety standards.

- Thicker wire = higher ampacity

- Thinner wire = lower ampacity

In South Africa, where electrical safety standards are paramount, selecting the correct gauge isn’t just a matter of convenience—it’s a legal necessity. Whether for residential wiring or industrial applications, understanding the relationship between gauge number and current-carrying capacity safeguards your investments and peace of mind. Remember, choosing the right **electrical cable gauge** is essential for safe, efficient, and reliable electrical systems—because no one wants their wiring to be the weak link in the circuit chain.

Importance of Proper Gauge Selection

Preventing Electrical Failures – Risks of undersized or oversized cables

Choosing the correct electrical cable gauge is not merely a matter of convenience; it’s a foundational pillar of electrical safety. An undersized cable can overheat, leading to insulation failure, short circuits, or even catastrophic fires—risks that threaten both property and lives. Conversely, an oversized cable, while seemingly safer, introduces unnecessary expense and rigidity, complicating installation without tangible benefit. The delicate balance hinges on understanding the precise load requirements and environmental conditions.

Imagine a scenario where the wrong gauge causes a critical connection to falter under peak demand. Such failures are often rooted in neglecting the importance of proper gauge selection. To prevent this, engineers and electricians meticulously evaluate current capacity and voltage drop, ensuring that each electrical cable gauge aligns with the unique demands of the circuit. This nuanced approach safeguards against potential failures and ensures compliance with safety standards, ultimately fostering durability and peace of mind.

Ensuring Efficiency – Optimizing performance with correct gauge

The significance of selecting the correct electrical cable gauge cannot be overstated; it is the silent guardian of electrical efficiency and safety. An optimal gauge ensures that power flows seamlessly, minimizing energy loss and reducing the risk of overheating—a danger lurking silently within the hidden corridors of wiring systems. When the gauge aligns precisely with the load requirements, it not only safeguards against potential failures but also bolsters the longevity of the entire electrical infrastructure.

Choosing the right electrical cable gauge is a nuanced dance between capacity and practicality. Oversized cables, although seemingly more robust, introduce unnecessary rigidity and cost, complicating installations without delivering proportional benefits. Conversely, undersized cables strain under peak demand, risking overheating and short circuits that can escalate into costly repairs or dangerous fires. Engineers and electricians meticulously evaluate current capacity, voltage drop, and environmental conditions to determine the ideal gauge, ensuring optimal performance and adherence to safety standards.

In the realm of electrical wiring, precision is paramount. The right gauge acts as a conduit for efficiency, empowering electrical systems to operate flawlessly under varying loads. It’s a delicate balance—one that hinges on understanding that the right electrical cable gauge is not merely an accessory but a vital component of resilient, efficient, and safe electrical networks.

Safety First – Reducing fire hazards and safety compliance

In the realm of electrical engineering, the choice of electrical cable gauge is akin to selecting the right enchanted blade—precision and purpose dictate its power and safety. A misstep in gauge selection can unleash chaos, turning what should be a conduit of safety into a potential harbinger of fire hazards. Ensuring the correct electrical cable gauge is not merely a technical detail but a vital safeguard that shields homes and workplaces from unseen dangers.

When electrical cable gauge aligns with load demands, it acts as an invisible guardian, preventing overheating and the subsequent risk of fires. Safety compliance standards in South Africa emphasize the importance of precise gauge selection, especially in environments exposed to diverse weather conditions or high demand. An improperly gauged wire, whether too thin or too thick, can compromise the integrity of the entire electrical system. It’s a delicate dance—matching the gauge to the load and environmental factors—ensuring both safety and efficiency without risking costly failures.

Common Mistakes to Avoid When Choosing Cable Gauge

Ignoring Load Calculations – Risks of not considering electrical load

Ignoring load calculations when selecting an electrical cable gauge is a perilous oversight, often leading to disastrous consequences. Many underestimate how crucial it is to match the cable gauge precisely with the anticipated load; after all, a wire too thin for the task is a ticking time bomb. When the load exceeds what the electrical cable gauge can handle, it results in overheating, potential fires, and damage to appliances—an expensive and dangerous misjudgment.

A common mistake is assuming standard gauges suffice without considering specific household or industrial demands. For example, heavy-duty applications require thicker gauges, yet some overlook this fact, risking safety and compliance. Remember, the right electrical cable gauge isn’t just about capacity; it’s about ensuring longevity, safety, and efficiency in every connection. Ignoring these vital load calculations is akin to driving a sports car on a dirt road—unnecessary risk with potentially catastrophic results.

Using Incorrect Wire Materials – Copper vs. aluminum issues

Choosing the correct electrical cable gauge isn’t just a matter of picking a number off a chart; it’s a decision rooted in safety, efficiency, and longevity. One common mistake homeowners and even some professionals make is selecting the wrong wire material—particularly confusing copper and aluminum wiring. While both are used widely in electrical systems, they have different properties that significantly influence the correct cable gauge to use.

Copper, known for its excellent conductivity and flexibility, generally requires a smaller gauge for the same capacity compared to aluminum. Aluminum, being lighter and less expensive, has a lower conductivity, meaning you need a thicker gauge to handle the same electrical load. Failing to account for this difference can lead to dangerous overheating or fire hazards. For example, using an aluminum wire with a gauge suitable for copper can result in insufficient current-carrying capacity.

It’s essential to understand that an incorrect electrical cable gauge based on wire material may compromise safety and violate local standards. Always verify whether copper or aluminum wiring is appropriate for your application, and select the right gauge accordingly. This careful attention ensures your electrical system remains resilient—protecting your home and loved ones from unforeseen dangers.

Overlooking Local Codes – Importance of adhering to electrical standards

Choosing the correct electrical cable gauge is more than a simple matter of numbers; it’s a moral decision rooted in safety and responsibility. Yet, one of the most common mistakes made in the process is overlooking local codes—an oversight that can have devastating consequences. South African electrical standards are designed to protect lives and property, but they are often ignored or misunderstood by those eager to cut corners.

Failing to adhere to these standards isn’t just risky—it’s reckless. When the electrical cable gauge selected doesn’t meet local regulations, the system becomes a ticking time bomb. Overloaded wires, overheating, or even fires can emerge from this negligence. It’s essential to recognize that the standards are not arbitrary but rooted in a deep understanding of electrical load, material properties, and safety protocols.

To truly respect the integrity of your electrical system, always verify compliance with local electrical codes before choosing the cable gauge. Remember, safety and legality are intertwined—ignoring this crucial step can lead to catastrophic failure. The right gauge, chosen with precision and adherence to standards, is the silent guardian of your home’s resilience against unseen dangers.

Tools and Resources for Determining the Correct Gauge

Gauge Calculators and Charts – Using online tools and printable charts

When navigating the intricate world of electrical wiring, having the right tools at your fingertips can make all the difference. Online electrical cable gauge calculators have revolutionized the way professionals and DIY enthusiasts approach gauge selection. These intuitive digital tools allow you to input variables like load requirements, wire length, and material type to receive precise gauge recommendations. Complementing these are printable charts—timeless resources that serve as quick references during on-site assessments or during the planning phase.

For those who prefer a more tactile approach, these printable charts display standardized gauge ranges, wire diameters, and current capacities, making them invaluable for ensuring safety and compliance. As you harness these resources, remember that choosing the correct electrical cable gauge is essential to prevent overheating, reduce fire hazards, and optimize electrical performance. Whether you’re working on a residential project or a commercial installation, these tools empower you to make informed decisions with confidence, rooted in accuracy and safety.

Consulting Professionals – When and why to seek expert advice

In the complex realm of electrical wiring, precision can be a matter of life and safety. When choosing the correct electrical cable gauge, consulting professionals becomes almost an imperative. Their expertise ensures that every wire not only meets safety standards but also maximizes efficiency, especially in demanding industrial environments or intricate residential setups.

Seeking expert advice is essential when dealing with unique load requirements or unconventional installation conditions. An electrical cable gauge that’s perfect for a standard home might fall short in a commercial or outdoor setting. Here, specialists can assess variables such as local electrical codes and material specifics—copper versus aluminum—that influence gauge selection.

For those venturing into complex projects, a professional consultation can prevent costly oversights. They often rely on tools like advanced load calculators and in-depth knowledge of current capacity standards. Remember, the right gauge isn’t just about compliance—it’s about safeguarding lives and ensuring peak electrical performance in every scenario.

Manufacturer Guidelines – Following product-specific recommendations

Choosing the correct electrical cable gauge isn’t just a matter of convenience — it’s a crucial step in ensuring safety and efficiency in any electrical installation. To navigate this complex terrain, reliable tools and resources are indispensable. Manufacturers often provide detailed guidelines that serve as the foundation for selecting the right gauge, especially when dealing with specific materials like copper or aluminum. These guidelines help prevent common pitfalls such as overloading or undersizing wires, which can lead to dangerous failures.

Modern electrical professionals increasingly lean on gauge calculators and charts—powerful online tools that simplify complex calculations. These resources consider variables like wire length, load requirements, and voltage drop, making it easier to match the electrical cable gauge precisely to your project’s demands. For those preferring a tangible reference, printable charts from reputable manufacturers can be invaluable, offering quick, at-a-glance guidance in the field.

In South Africa, where electrical standards are tightly regulated, consulting manufacturer guidelines alongside local codes ensures compliance and safety. Whether it’s a residential setup or a heavy-duty industrial application, utilizing these tools and resources helps avoid costly mistakes and guarantees that every wire is fit for purpose. Remember, the right electrical cable gauge isn’t just a technical detail—it’s the backbone of a safe, reliable electrical system.

Future Trends in Electrical Cable Gauges

Advancements in Material Technology – New materials impacting gauge standards

As the landscape of electrical engineering evolves, so too does the framework governing electrical cable gauge standards—driven increasingly by breakthroughs in material technology. New composite materials, such as high-performance polymers and innovative alloys, are redefining the boundaries of what cable gauge can achieve, especially in terms of flexibility, durability, and conductivity. These advancements allow for thinner, more efficient cables without sacrificing safety or performance, which is particularly vital in the context of South Africa’s diverse infrastructure needs.

In particular, the adoption of advanced materials influences how we interpret electrical cable gauge specifications. Instead of relying solely on traditional copper or aluminum, engineers now consider hybrid and nanomaterial-infused conductors that push the envelope of current capacity and thermal stability. This shift not only optimizes cable performance but also expands the possibilities for energy efficiency and safety compliance, especially in high-demand environments.

- Reduced gauge sizes for similar or increased loads

- Enhanced resistance to environmental stressors such as corrosion and temperature fluctuations

- Improved flexibility, facilitating installation in confined spaces

Looking ahead, these material innovations are poised to revolutionize how electrical cable gauge is determined, enabling safer, more sustainable, and cost-effective electrical systems across residential, commercial, and industrial sectors. As the market embraces these cutting-edge materials, the future of cable gauge standards promises a fascinating interplay between scientific ingenuity and practical application, ensuring that electrical infrastructure keeps pace with the demands of modern society.

Smart Wiring and IoT Applications – How modern tech influences gauge needs

As technology accelerates into an era where connectivity and energy efficiency are paramount, the trajectory of electrical cable gauge standards is undergoing a profound transformation. The advent of smart wiring and the proliferation of IoT applications demand a reevaluation of traditional gauge paradigms, pushing the boundaries of what conventional copper and aluminum conductors can achieve. In South Africa’s rapidly evolving infrastructure landscape, this shift is not merely academic; it has tangible implications for safety, performance, and sustainability.

Innovations in materials and design are enabling the development of ultra-thin, high-capacity cables capable of supporting the burgeoning network of connected devices. These advancements facilitate the integration of complex IoT systems within residential, commercial, and industrial settings, where space constraints and energy demands collide. As a result, electrical cable gauge selections are increasingly driven by the need for enhanced flexibility, thermal stability, and environmental resilience, especially in outdoor or harsh conditions.

Furthermore, the future of electrical cable gauge is intertwined with the rise of smart systems that monitor and optimize energy consumption in real-time. This evolution enhances not only operational efficiency but also safety, as better gauge choices reduce the risk of overheating and electrical failures. The convergence of innovative materials, intelligent design, and digital integration promises a landscape where electrical cable gauge will become more dynamic and adaptive—an essential enabler for South Africa’s energy future.

Eco-friendly and Energy-efficient Wiring – Sustainable practices affecting cable choices

As South Africa’s energy landscape evolves, so too does the future of electrical cable gauge. Eco-friendly and energy-efficient wiring practices are no longer optional—they are essential for sustainable development. Innovations in materials—such as biodegradable insulations and high-conductivity composites—are driving a new wave of ultra-thin, high-capacity cables. These advancements enable more power to flow through less space, making them ideal for smart wiring and IoT applications.

Environmental considerations are pushing manufacturers to prioritize eco-friendly options without compromising safety or performance. In particular, cable gauges designed with recycled materials reduce waste and carbon footprint, aligning with South Africa’s green energy ambitions. This shift also influences the selection process, with a focus on minimizing energy loss and ensuring thermal stability in diverse conditions.

- Increased adoption of lightweight, flexible cables that support complex IoT networks.

- Development of smart cables capable of self-monitoring for overheating or faults, enhancing safety.

- Utilization of sustainable materials that sustain durability in outdoor and harsh environments.

Ultimately, the future of electrical cable gauge hinges on balancing energy efficiency with environmental responsibility. As technology advances, so will the capacity for smarter, greener wiring solutions—transforming the landscape of South African infrastructure and powering a more sustainable tomorrow.