Understanding Electrical Cable Grommets

What Are Electrical Cable Grommets?

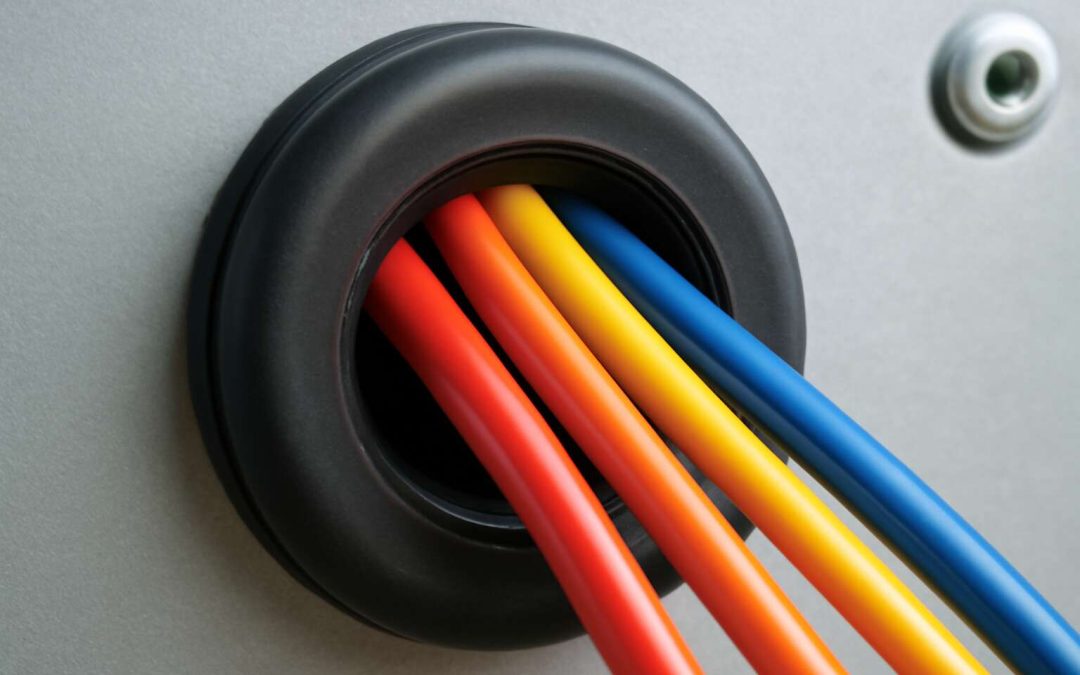

Electrical cable grommets might sound like tech jargon, but in the world of wiring, they’re the unsung heroes—those little rubber or plastic rings that keep your cables cozy and your equipment safe. Think of them as the bouncers of the electrical world, preventing cable chaos and shielding wires from the brutal reality of sharp metal edges and abrasive surfaces.

What exactly are electrical cable grommets? Simply put, they are protective fittings inserted into holes in panels, enclosures, or walls. They serve a crucial role: providing a smooth, rounded edge for cables to pass through, which helps prevent insulation damage and reduces wear and tear over time. This seemingly simple component is vital for maintaining the integrity of electrical systems, especially in high-stakes environments like South African factories or home workshops where ruggedness is a must.

- They help prevent electrical shorts

- Make cable management neater and safer

- Extend the lifespan of your wiring

Materials Used in Grommets

In the shadowy realm of electrical components, the materials used in manufacturing electrical cable grommets are the silent guardians of durability and performance. Often crafted from rubber or plastic, these materials are chosen for their resilience against the relentless assault of environmental elements and mechanical stress. The choice of material can truly make or break the longevity of your wiring system, especially in the rugged terrains of South Africa where exposure to dust, moisture, and abrasive surfaces is relentless.

Rubber grommets, revered for their flexibility and shock absorption, are ideal for environments prone to vibration and sudden impacts. Meanwhile, plastic variants—specifically thermoplastics—offer a lightweight yet sturdy alternative, resistant to chemicals and corrosion. For those seeking superior durability, some electrical cable grommets incorporate a blend of materials, creating a fortress that shields cables from the brutal realities of industrial settings.

Understanding the composition of these grommets reveals their true purpose: to serve as the first line of defense against damage, electrical shorts, and premature wear. As the macabre dance of wires continues behind the scenes, these seemingly humble components stand as sentinels—silent, steadfast, and essential.

Types of Cable Grommets

In the shadowed corridors of electrical installations, the variety of electrical cable grommets reveals a silent symphony of purpose and precision. These components come in diverse forms, each crafted to serve a specific role in shielding cables from the relentless assault of environmental foes and mechanical threats. Understanding the different types of electrical cable grommets can unlock the secret to a resilient wiring system, especially in the unpredictable terrains of South Africa where dust, moisture, and abrasive surfaces lurk around every corner.

Among the most common variants are the standard rubber grommets, revered for their flexibility and shock absorption, making them ideal for vibration-prone environments. Plastic grommets, often made from robust thermoplastics, provide a lightweight yet durable barrier against chemicals and corrosion. For more demanding industrial settings, some grommets feature a hybrid composition—melding materials to forge an impenetrable fortress against wear and tear.

To navigate this labyrinth of choices, consider these primary types of electrical cable grommets:

- Rubber Grommets

- Plastic Grommets

- Sealing Grommets

- Reinforced Grommets

Each type is designed with a unique purpose, yet all share the common goal of preserving the integrity of your cables, ensuring they remain unscathed behind the scenes of your electrical system. The selection of the right grommet becomes not just a matter of functionality but a safeguard against the relentless forces of nature and industry’s harsh realities, standing as a testament to the silent guardianship of these unassuming yet vital components.

Key Features and Benefits

Electrical cable grommets are often overlooked, yet they are the unsung heroes of safe and durable wiring systems. Their key features include flexibility, durability, and resistance to environmental factors, making them essential in protecting cables from damage. In areas prone to dust, moisture, and rough conditions—like many parts of South Africa—these components provide a vital barrier that keeps cables intact and functioning optimally.

One of the most significant benefits of electrical cable grommets is their ability to prevent abrasion and cut-through, which can lead to costly failures or safety hazards. They also reduce vibrations and noise, contributing to a quieter, more stable electrical setup. Their adaptability allows them to fit various cable sizes and installation environments, ensuring a snug, protective seal every time.

Choosing the right grommet involves understanding the specific demands of your environment. Whether you need rubber grommets for shock absorption or sealing grommets to keep out moisture, each type offers tailored solutions. The right selection ensures your cables remain protected against the relentless forces of nature and industrial wear, ultimately extending the lifespan of your electrical system.

Applications of Cable Grommets

Industrial Equipment

In the bustling corridors of industrial equipment, electrical cable grommets serve as silent guardians, safeguarding vital connections from the relentless march of wear and tear. These unassuming accessories are pivotal in environments where heavy machinery and high-voltage systems intertwine, ensuring safety and longevity. When cables traverse through panels or enclosures, the application of electrical cable grommets becomes a strategic move to prevent abrasion, insulation damage, and potential electrical faults.

From manufacturing plants to maritime machinery, the versatility of electrical cable grommets is truly remarkable. They are often employed in:

- Control panels that demand meticulous cable management

- Heavy-duty machinery exposed to vibration and movement

- Electrical enclosures safeguarding sensitive components

In these settings, the grommets act as a resilient buffer, absorbing shocks and preventing sharp edges from compromising cable integrity. Their adoption is not just about protection; it’s about ensuring that the pulse of industrial operations remains uninterrupted and secure!

Electrical Enclosures

In the intricate dance of industrial progress, electrical cable grommets occupy a silent but vital role. Their application within electrical enclosures is more than mere protection — it is a moral imperative to preserve the integrity of vital connections in environments where chaos and vibration threaten to unravel the very fabric of safety. These components serve as a resilient barrier, preventing abrasion, insulation damage, and electrical faults that could spell disaster.

Electrical enclosures are often the unseen guardians of sensitive equipment, and the inclusion of electrical cable grommets ensures that cables pass through these barriers with grace and security. Whether in control panels, heavy-duty machinery, or maritime environments, they help manage complex wiring systems, reducing wear and tear over time. In some cases, their use extends to:

- Protecting cables from sharp edges that could sever insulation

- Absorbing vibrations to prevent fatigue

- Facilitating organized cable management in confined spaces

In this web of interconnected systems, electrical cable grommets are more than just accessories—they are the unsung heroes that uphold operational longevity and safety. Their strategic placement ensures that the pulse of industrial activity continues unabated, undeterred by the chaos of the environment. When cables are passed through enclosures, these small yet formidable components serve as the moral backbone of electrical safety, embodying resilience in the face of relentless wear.

Automotive Wiring

When it comes to automotive wiring, electrical cable grommets are the unsung heroes that keep everything running smoothly—and safely. In the high-octane world of vehicle manufacturing and maintenance, these tiny components play a monumental role in protecting wiring systems from the relentless onslaught of vibration, heat, and rough terrain. Without them, cables risk being shredded by sharp edges or worn down over time, leading to potential electrical failures or, worse, fires.

In South Africa’s rugged landscapes and bustling highways, durability is non-negotiable. Electrical cable grommets ensure that wiring passing through engine compartments, dashboards, or chassis panels are shielded from abrasion and environmental stressors. Their application isn’t limited to just new builds; they are crucial during repairs and upgrades, providing a safeguard that prolongs the lifespan of the entire electrical system.

For those seeking an organized and resilient wiring setup, consider the following:

- Routing cables neatly through tight spaces without risking damage

- Preventing insulation cuts that could lead to shorts or failures

- Absorbing vibrations that would otherwise cause fatigue and disconnection

In the realm of automotive wiring, electrical cable grommets are more than just rubber rings—they are the frontline defenders of electrical integrity, ensuring your vehicle’s wiring stays intact amidst the chaos of the road.

Marine and Outdoor Use

When it comes to marine and outdoor applications, electrical cable grommets are the silent guardians against the relentless assault of the elements. In South Africa’s coastal regions and rugged terrains, exposure to saltwater, UV rays, and moisture is unavoidable. These environments demand a level of durability that only specialized electrical cable grommets can provide. They serve as a vital barrier, shielding wiring from corrosion, abrasion, and environmental stressors that could compromise electrical integrity.

Whether installed on boats, outdoor signage, or electrical enclosures exposed to the elements, these grommets prevent water ingress and reduce wear on cables. Their ability to maintain a tight seal ensures that moisture doesn’t seep through, averting corrosion and electrical failures. For outdoor and marine environments, selecting the right electrical cable grommets is paramount, as they must withstand harsh conditions without deteriorating or losing their protective qualities.

- Sealing cables passing through boat hulls and decks

- Protecting outdoor lighting fixtures from environmental damage

- Ensuring long-term durability of wiring in outdoor industrial setups

In the unpredictable South African climate, electrical cable grommets are more than just accessories—they are essential components that preserve the safety and functionality of electrical systems in marine and outdoor settings. Their resilience and sealing capabilities make them indispensable for projects where exposure to the elements is a constant threat.

Factors to Consider When Choosing a Grommet

Size and Diameter

Choosing the right size and diameter for electrical cable grommets is crucial for effective cable management and safety. An ill-fitting grommet can compromise insulation and lead to premature wear or damage. When selecting a grommet, consider the diameter of the cable to ensure a snug fit that prevents movement and abrasion.

A good rule of thumb is to measure the cable diameter accurately—remember, a slightly larger grommet can accommodate different cable sizes while maintaining a tight seal. For multiple cables passing through a single opening, opt for a grommet that can handle the combined diameter without stretching or tearing.

In some cases, flexible or multiple-channel grommets are advantageous, especially when future upgrades or additional wiring are anticipated. The goal is to balance protection with ease of installation, ensuring that your electrical cable grommets provide a durable, reliable barrier against environmental factors and mechanical stress.

Material Compatibility

Choosing the perfect material for electrical cable grommets is akin to selecting the right fabric for a tapestry—each thread must harmonize with its environment to withstand the test of time. In South Africa’s diverse climate, where coastal humidity, arid heat, and sudden downpours are common, the material must be resilient and compatible with its surroundings. The wrong choice can lead to deterioration, exposing cables to potential damage and jeopardizing safety.

When considering material compatibility, think about the environment in which the electrical cable grommets will operate. For outdoor use, UV-resistant and weatherproof options like rubber or silicone are often ideal, offering flexibility and longevity. Conversely, in industrial settings, high-temperature or chemical-resistant grommets made from specialized polymers may be required. Here are some factors to ponder:

- The exposure to environmental elements such as moisture, dust, or chemicals

- The temperature range the grommets must endure

- The compatibility with other materials, preventing galvanic corrosion or degradation

Ensuring material compatibility is not merely about durability—it’s about safeguarding the integrity of your electrical system while maintaining ease of installation. When selecting electrical cable grommets, envision them as guardians, silently but steadfastly protecting your cables against the relentless forces of nature and time.

Environmental Resistance

Choosing the right electrical cable grommets isn’t just about fitting a hole; it’s about ensuring your cables can brave South Africa’s wild climate without throwing a tantrum. Environmental resistance is the secret sauce—think of it as giving your grommets a superhero cape. Moisture, dust, and chemicals are relentless foes, so selecting grommets with superior weatherproof qualities is essential. If your setup faces direct sunlight or harsh outdoor elements, UV-resistant options will keep degradation at bay, extending the lifespan of your electrical cable grommets.

Temperature fluctuations are another factor that can turn a simple installation into a fiery ordeal. High-temperature grommets made from specialized polymers will prevent melting or cracking, while chemical-resistant variants shield against corrosive substances common in industrial or marine environments. Remember, in South Africa’s unpredictable weather, your grommets must be more than just pretty—they need to be tough enough to survive the elements.

Ease of Installation

Installing electrical cable grommets might seem as mundane as threading a needle, but trust me, ease of installation can make or break your project—and save you from a world of frustration. In South Africa’s rugged environment, where dust and debris are just part of the daily grind, you want a grommet that slips in seamlessly without causing a headache. The good news? Many modern electrical cable grommets are designed with user-friendliness in mind, featuring quick-fit designs or snap-in features that cut installation time dramatically.

When choosing the right grommet, look for options that offer flexibility in installation, especially if you’re working in tight or awkward spaces. Some grommets come with pre-drilled holes or come with easy-to-follow instructions, making the process almost foolproof. Remember, a well-chosen grommet doesn’t just protect your cables; it also saves you time and effort during setup—because who wants to wrestle with stubborn parts when you could be tackling more pressing job site challenges?

For those tackling complex projects, consider the importance of compatibility with existing setups. A grommet that’s too stiff or cumbersome to install can lead to damage during fitting, undermining the very purpose of choosing quality electrical cable grommets. Prioritize products that combine durability with straightforward installation—your future self will thank you when the cables are snug, secure, and ready to face South Africa’s unpredictable weather!

Compliance and Certifications

When selecting the perfect electrical cable grommets, compliance and certifications are often the unsung heroes of a successful installation. In South Africa’s unpredictable climate—where dust, humidity, and temperature swings are routine—it’s vital that your grommets meet stringent safety standards. Certifications such as SABS (South African Bureau of Standards) approval or ISO compliance aren’t mere bureaucratic checkboxes; they are assurances that your electrical cable grommets have been rigorously tested for durability, safety, and environmental resilience.

Moreover, choosing products with reputable compliance credentials can save you from costly rework or, worse, safety hazards. Some key certifications to look for include:

- SABS certification for local standards adherence

- ISO 9001 for quality management systems

- IEC standards for electrical safety

In essence, ensuring your electrical cable grommets are certified isn’t just about ticking boxes—it’s about safeguarding your project, your team, and the longevity of your electrical infrastructure in the rugged South African environment.

Installation Tips for Cable Grommets

Preparation and Precautions

Proper installation of electrical cable grommets is crucial to ensure long-term safety and functionality. A common mistake is rushing the process; taking the time to prepare the opening correctly can prevent future damage. Before installing, double-check the size and compatibility of the grommet with your cable to avoid unnecessary wear or electrical faults. When preparing the panel or enclosure, smooth out any rough edges around the hole—sharp edges can compromise the integrity of the cable grommet and lead to insulation damage.

To make installation seamless, consider applying a small amount of lubricant or silicone spray to the grommet’s edge. This reduces friction and makes fitting easier, especially in tight spots. If you’re working with multiple cables, organize and label them beforehand to streamline the process. Remember, safety is paramount—wear protective gloves and eye gear to prevent injury. Lastly, always verify that the electrical cable grommets used meet the necessary compliance and certification standards for your project’s environment. Proper preparation and cautious handling ensure your cables stay protected against environmental factors and mechanical stress.

Step-by-Step Installation Guide

Contrary to popular belief, installing electrical cable grommets is not a task for the impatient or the faint-hearted. A slip-up here can turn a simple project into a hazardous affair—think frayed insulation or, worse, electrical faults. To avoid such pitfalls, a meticulous approach is paramount. Start by selecting the correct size of the electrical cable grommet; a snug fit not only looks professional but also ensures robust protection against environmental assault.

Next, gently insert the grommet into the prepared hole, but don’t rush—applying a smear of silicone spray around the edge can make the process smoother, especially in tight spaces. For multiple cables, organize and label them beforehand; chaos in wiring is a recipe for disaster. Remember, patience during installation not only prolongs the lifespan of the electrical cable grommet but also keeps your wiring system compliant with safety standards. Once fitted, double-check for any gaps or misalignments—attention to detail can save hours of troubleshooting later.

Common Mistakes to Avoid

In the shadowed corridors of electrical craftsmanship, even the smallest detail can spell the difference between safety and catastrophe. When installing electrical cable grommets, one common mistake lurks in the darkness: forcing the grommet into a hole that’s either too tight or too loose. Such missteps can compromise the integrity of your wiring, exposing cables to frayed insulation or environmental damage. To avoid this, always verify the size of the electrical cable grommet before proceeding—an ill-fitting grommet is a silent harbinger of future troubles.

Another perilous pitfall is neglecting the organization of multiple cables. Chaos in wiring is not just an aesthetic flaw; it’s an invitation for electrical faults. For complex installations, consider using a systematic approach, such as:

- Label each cable thoroughly to track its purpose and pathway.

- Maintain a tidy arrangement inside the conduit or enclosure.

- Ensure each electrical cable grommet is seated securely without gaps or misalignments.

Applying a light coating of silicone spray can ease the insertion process, especially when working within confined or awkward spaces. Patience, a virtue in the dark art of electrical installation, ensures that each grommet not only fits snugly but also preserves the longevity of your wiring system. Remember, haste can unravel the delicate tapestry of electrical safety, turning a straightforward task into a hazardous ordeal. Embrace meticulousness—your wiring, and perhaps even your life, depend on it.

Maintenance and Troubleshooting

Inspecting Grommets for Wear and Damage

Regular inspection of electrical cable grommets is often overlooked, yet it is vital for maintaining the integrity of your wiring system. Even the most durable electrical cable grommets can succumb to wear and tear over time, especially when exposed to harsh environmental conditions or mechanical stress. Neglecting these signs can lead to compromised insulation, increased risk of electrical faults, or even short circuits—outcomes that any professional or hobbyist would prefer to avoid.

During routine maintenance, it’s essential to thoroughly examine each grommet for cracks, deformation, or signs of deterioration. Damaged grommets no longer provide the necessary cushioning and protective barrier for cables passing through panels or enclosures. To assist in this process, you might consider creating a checklist:

- Check for visible cracks or tears in the grommet material

- Ensure the grommet remains securely seated in its opening

- Look for signs of discoloration or brittleness that indicate aging

By adopting a proactive approach to troubleshooting and inspecting electrical cable grommets, you can prevent costly repairs and ensure consistent electrical safety across your installations. It’s a small step that preserves the longevity of your wiring and highlights the importance of meticulous maintenance in complex electrical systems.

Replacing Old or Damaged Grommets

Over time, even the best electrical cable grommets can become brittle or cracked. Regular maintenance is crucial to prevent potential hazards in your electrical system. When replacing old or damaged grommets, it’s vital to choose the correct size and material to ensure optimal protection. Damaged grommets no longer cushion the cables, increasing the risk of insulation failure or short circuits.

During troubleshooting, inspect each grommet carefully. Look for signs of wear, such as tears or discoloration. A quick visual check can save time and money in the long run. If a grommet shows any damage, replace it immediately. Using the right tools and following proper installation procedures ensures that the new grommets stay secure and provide a reliable seal. Remember, maintaining your electrical cable grommets is a simple step that significantly enhances safety and prolongs your wiring’s lifespan.

Ensuring Proper Sealing and Insulation

Ensuring proper sealing and insulation with electrical cable grommets is essential for the longevity and safety of any electrical system. Over time, even the most durable grommets can deteriorate—cracking, tearing, or becoming discolored—compromising their protective function. Regular maintenance involves inspecting these grommets for signs of wear, especially in environments exposed to moisture or extreme temperatures. A thorough visual check can reveal cracks or brittleness that might otherwise go unnoticed.

If damaged, replacing old or compromised grommets promptly is crucial. Proper installation not only guarantees a secure fit but also maintains an effective seal, preventing dust, water, and pests from infiltrating electrical enclosures. Remember, the integrity of your electrical cable grommets directly impacts insulation durability and reduces the risk of short circuits or electrical failures, safeguarding both personnel and equipment.

Where to Buy Quality Electrical Cable Grommets

Trusted Suppliers and Brands

Finding reliable sources for high-quality electrical cable grommets is essential for ensuring safety and durability in any electrical installation. In South Africa, trusted suppliers and brands are the cornerstone of a successful project, offering products that meet stringent standards and environmental demands. When sourcing electrical cable grommets, it’s crucial to partner with vendors that prioritize quality, compliance, and innovation—attributes that safeguard your wiring against wear, moisture, and mechanical stress.

Many reputable suppliers now operate both online and through specialized distributors, making it easier than ever to access premium electrical cable grommets. A good starting point is to look for brands that are recognized for their adherence to international safety standards, such as ISO and local certification bodies. For those seeking top-tier options, here are some trusted suppliers known for their superior products:

- Global industrial suppliers with a dedicated South African branch

- Specialist electrical component distributors with extensive catalogs

- Local manufacturers committed to innovative and environmentally resistant grommets

By choosing established brands and trusted suppliers, you ensure the longevity and reliability of your electrical systems. Whether you’re outfitting industrial equipment, electrical enclosures, or automotive wiring, sourcing from reputable vendors guarantees that your electrical cable grommets will perform seamlessly, protecting your wiring while contributing to safer, more resilient installations across South Africa’s diverse environments.

Bulk Purchasing and Custom Options

Finding the right source for bulk purchasing of high-quality electrical cable grommets can significantly streamline your project costs and ensure consistent quality. Many suppliers in South Africa offer specialized options tailored to meet diverse industry needs, from industrial machinery to automotive wiring. Opting for reputable vendors not only guarantees compliance with safety standards but also provides the flexibility to explore custom options, such as specific sizes or environmentally resistant materials.

When considering where to buy electrical cable grommets in bulk, look for suppliers that provide extensive catalogs and flexible ordering options. Some companies even offer bespoke grommet solutions, allowing you to select materials, diameters, or environmental resistance features that suit your unique application. This customization ensures your wiring remains protected against moisture, abrasion, and mechanical stress in any environment. Whether you’re outfitting a large manufacturing plant or a specialized automotive project, sourcing from trusted suppliers with a focus on quality and innovation is paramount.

Pricing and Value

Finding the right source for quality electrical cable grommets at a competitive price can make a significant difference in project budgets. In South Africa, many suppliers offer a range of options that balance affordability with durability. It’s worth exploring vendors who specialize in electrical cable grommets, as they often provide better value and consistent quality compared to generic alternatives.

Many reputable suppliers offer transparent pricing structures and flexible bulk purchasing options. Whether you need a few pieces for a small project or large quantities for industrial setups, sourcing from established vendors ensures you get the best value for your money. Some suppliers even provide detailed catalogs that help you compare different materials, sizes, and environmental resistance features, so you can choose exactly what suits your application. This tailored approach guarantees your wiring remains protected while keeping costs manageable.

For those seeking optimal value, consider suppliers that offer competitive pricing on bulk orders of electrical cable grommets—an investment that ensures longevity and safety for your wiring systems. By prioritizing trusted brands and suppliers committed to quality, you can secure the best balance of price and performance, critical for any professional electrical installation or industrial project in South Africa.

Future Trends and Innovations in Cable Grommets

Eco-Friendly Materials

As the world leans more toward sustainability, the future of electrical cable grommets is taking an eco-friendly turn that’s both exciting and necessary. Companies are now exploring materials that reduce environmental impact without sacrificing durability or performance. Imagine a cable grommet that’s biodegradable or made from recycled plastics—sounds like a win-win, right? These innovations not only help lower carbon footprints but also align with global regulations on environmental responsibility.

In fact, some forward-thinking manufacturers are pioneering the use of plant-based rubber compounds and bio-based polymers in electrical cable grommets. This shift opens a new chapter where sustainability and safety go hand in hand. Additionally, the development of smart grommets equipped with sensors could revolutionize how we monitor cable insulation and wear, potentially alerting users before issues become costly or hazardous.

- Use of recycled and biodegradable materials

- Integration of smart technology for real-time monitoring

- Enhanced durability with eco-conscious compounds

With these innovations, the next generation of electrical cable grommets promises to be more than just protective barriers—they’ll be pivotal in creating a greener, smarter infrastructure. It’s a future that’s both resilient and eco-aware, ensuring our cables are as sustainable as they are secure.

Advanced Installation Designs

Future trends in electrical cable grommets are shaping up to be nothing short of revolutionary. Advanced installation designs are making the process quicker, safer, and more intuitive—think snap-fit mechanisms and modular grommet systems that practically install themselves. These innovations aim to reduce downtime and minimize the chances of damaging cables during installation, a common headache in industrial settings.

On the innovation front, smart grommets equipped with sensors are set to become the new norm. These intelligent electrical cable grommets can monitor cable insulation status in real-time, alerting users to wear or potential failure before catastrophe strikes. Imagine a world where your cable management system warns you about impending issues—talk about peace of mind! Moreover, future designs will likely include eco-friendly materials that are biodegradable or made from recycled plastics, aligning with global sustainability goals.

To truly harness the benefits of these advancements, manufacturers are focusing on:

- Enhanced ease of installation with ergonomic and modular designs

- Integration of smart technology for proactive maintenance

- Use of durable, eco-conscious materials to extend lifespan and reduce environmental impact

As these trends unfold, it’s clear that the next generation of electrical cable grommets will be more than just protective barriers—they’ll be vital components in creating smarter, greener infrastructure. The future promises a seamless blend of innovation and sustainability, making cable management not only more efficient but also more environmentally responsible.

Enhanced Durability and Environmental Resistance

As technology advances at a dizzying pace, the future of electrical cable grommets is set to be nothing short of transformative. Enhanced durability and environmental resistance are at the forefront of these innovations, ensuring that cable management systems can withstand even the harshest South African climates—think scorching heat, relentless humidity, or salty coastal air. Modern designs are incorporating materials that resist UV degradation, corrosion, and extreme temperatures, extending the lifespan of electrical cable grommets and reducing costly replacements.

In addition, cutting-edge electrical cable grommets are embracing eco-friendly materials, such as biodegradable plastics and recycled polymers. These sustainable options align perfectly with global efforts to reduce plastic waste and carbon footprints. For example, some manufacturers are now offering grommets with increased resistance to chemicals and oils, making them ideal for industrial environments where exposure to aggressive substances is common.

- Superior resistance to environmental factors

- Use of eco-conscious materials for sustainability

- Enhanced mechanical strength to withstand vibration and impact

With these advancements, electrical cable grommets are evolving from simple protective barriers into highly resilient and eco-friendly components that play a vital role in reliable, sustainable electrical infrastructure. The emphasis on durability and environmental resistance guarantees that these grommets will keep cables safe, intact, and functioning seamlessly, long after traditional options have worn out or failed.